Posts Tagged vanagon

Vanagon – tire and wheel comparison

I just installed, at last, some new wheels and tires. I dithered for so long and ended up with a compromise. The wheels are Mercedes alloys,15″ x 7″, ET of 25. The tires are Yokohama Geolander ATS 215/70-15.

The offset is a bit lower than perfect, the wheels stick out a little more but that gives a tad more clearance on the suspension side and the sliding door clears tire by a good 3/8″.

Simon left his van with me while he is on a trip to an un-namable place so I had a chance to do a visual comparison” his wheels are 15″, ET 30, and I think 6.5″ wide, South African carats. The tires are nokian WRC, 205/70-15.

I have only riven a short distance on my new tires but I lie, what I feel so far. Smoother over bumps, little tire noise. They change the feel of the van in a very good way.

Here is quick vid of the two vans, Simon’s van is the high top.

Trip – Much of the same

Another weekend trip to favourite places. A little different this time as there was little fog. I hope the residents of Neah Bay across the straits took the opportunity to hang laundry.

Obligatory clear cut shots.

And one of our favourite creeks.

Saw lots of shipping with the lack of fog. Cruise ships, oil tankers, and container ships. a few of this kind went past. I like how the containers are stacked in a subtle wedge shape.

Came across a doe and new born fawn. Fawn was very shaky and wouldn’t get out of the way.

“and my axe”

Mmm, chicken

ok, another cheesy vid, this time the creek

Trip – same old same old, but finally the first trip of the year

For various reasons we haven’t managed to get out using the van for its intended purpose until this last weekend. It was just an overnighter to familiar places, but still a fun outing.

Driest May on record here this year, and the Thursday and Friday before we left felt like August. It wasn’t quite August out on the west coast, the wind was coolish, but the sun was warm.

The syncro was a champ, hauling us up loose gravel and rock logging spurs, and the newly installed big assed auxilliary battery didn’t even blink about the amount of electricity we used. The battery truly is way bigger than we will ever need, its both daft and kinda fun to have it.

And yes, we camped beside clearcuts 🙂

On our way, we realized we had left the Thai themed marinated chicken thighs back at home, so we picked up some meat strips in Sooke.

Where’s Waldo?

Vanagon – big battery installed

Posted by albell in vanagon, vanagon mods on May 24, 2015

It took longer than making a baby but I finally have my big battery installed. I got this Northstar 200 AHr battery some time ago, I think I mentioned it in this blog post. The size and shape of the battery made it seem like it would fit easily under the rear seat but it just doesn’t ( without taking up more space than it needs, if that makes sense). I toyed with the idea, and went as far as making brackets, of mounting it up under the van between the door sill and frame rail but no, that didn’t look right. So I settled upon the admittedly dubious spot of where the spare tire sits. A couple of problems with this placement. Number one is that I now have to find a spot for the spare tire. Ah but what about my much talked about swing away spare tire carrier? More on that at the end of the post. The other dubious characteristic of this battery location is that it places 128 lbs forward of the front wheels. I’m a little worried that it might make a difference in how the van negotiates dips and ditches in logging roads. Skipping a head a bit, I have had the battery installed for a week and I really don’t notice any driving different on paved roads. I made a carrier for the battery quite a while back, crikey, it was a year ago, since then I welded in some locating brackets that the battery fits into, and some tabs on the side tubes for supporting brackets. The brackets are made from 1X1/8″ stainless and I bent them to fit to the van frame rails. They are secured to the frame rails by 5/16″ stainless bolts that I will someday change to 8 mm. The bracket to the tab connection is done with 1/4-20 bolts and instead of nuts I used stainless ring nuts. The rings are to secure nylon straps that cross the battery and hold it very securely to the tray. Ok, some pics of it installed. First pic taken from driver’s side, one stainless bracket not fastened. Gives you the general idea of how the battery lies.

And on the passenger side. You can probably make out the red nylon hold down straps going up over the battery.

I had thought of making aluminum side splash plates but I was dissuaded by the changing angles and company curves needed so I used some scavenged treadmill material. I installed 1/4-20 riv nuts in the existing holes in the van frame and bolted the treadmill material.

It’s not great but it’s not bad. It’s just there to reduce water splashing on the battery. Not shown in the pic are tubes leading from the battery vent up over the battery and on up to behind the front grill. When I did that I was thinking I was clever, I thought that leading the vents up high would prevent water getting into the battery if I happened to go through a deep puddle. But I found out later that the battery vents have a valve in them to prevent water ingress. A note on the wiring. I ran a short length of 4 gauge wire from the negative terminal back to the bolt holding on the transverse member supporting the front differential. On the positive terminal a short length of 4 gauge comes off the terminal and up into a black box (attached by Velcro) on top of the battery. In that box is a Blue Seas Maxi Fuse block, with a 70 A fuse.

Update: in the comments Marius wondered about battery cold weather performance. Here is a graph I found in one of Northstar’s documents .

Then out of the box and through some plastic sheathing and a sealed bulkhead fitting into the battery compartment behind/under the driver’s seat. Then it continues on to connect with my Blue Seas ACR. I’ll write more on that when I tidy up the wiring, I’m going to change the auxiliary power distribution layout there. I was surprised and pleased to discover that when all is bolted up tight the stainless straps from the tray to the frame seem to support the entire weight of the battery. The bolts at the rear, where the tray hinges on, have no weight on them. So that pretty well sums up the installs the battery. As mentioned I will post more on the auxiliary power distribution set up when I finally fix the positions of the various components. So… The spare tire, where does it go? It’s time for a confession, I couldn’t get my swing away tire carrier to work the way I wanted to. I’m not going to explain all the things I tried, and I did try a lot of things. But I could not get happy with the rigidity of the set up. The tire vibrated in the carrier when I smacked it with my hand. It bugged me no end. I finally lost my patience and removed it, cut out the hinge from the bumper and welded the bumper back together and painted it. I’m going to make a hatch mounted tire carrier, don’t laugh… Yet. In the meantime I’ve pulled my old Paulchen rack out and I have the tire bolted on that.

Then out of the box and through some plastic sheathing and a sealed bulkhead fitting into the battery compartment behind/under the driver’s seat. Then it continues on to connect with my Blue Seas ACR. I’ll write more on that when I tidy up the wiring, I’m going to change the auxiliary power distribution layout there. I was surprised and pleased to discover that when all is bolted up tight the stainless straps from the tray to the frame seem to support the entire weight of the battery. The bolts at the rear, where the tray hinges on, have no weight on them. So that pretty well sums up the installs the battery. As mentioned I will post more on the auxiliary power distribution set up when I finally fix the positions of the various components. So… The spare tire, where does it go? It’s time for a confession, I couldn’t get my swing away tire carrier to work the way I wanted to. I’m not going to explain all the things I tried, and I did try a lot of things. But I could not get happy with the rigidity of the set up. The tire vibrated in the carrier when I smacked it with my hand. It bugged me no end. I finally lost my patience and removed it, cut out the hinge from the bumper and welded the bumper back together and painted it. I’m going to make a hatch mounted tire carrier, don’t laugh… Yet. In the meantime I’ve pulled my old Paulchen rack out and I have the tire bolted on that.

And the bumper… well its ok, but I’m not ecstatic about how far the end caps stick out, oh well maybe I can say it provides better side protection and its Mk I. And i still have to paint the tow loops and the receiver hitch.

Vanagon – kinda crazy sway bar mod to help install homemade drop links

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on April 25, 2015

This value of this modification to the sway bar is debatable. But hey, don’t let fear and good judgement hold you back from having a bit of fun. And god knows I’m not going to sit here and tell you this is an original idea, I’m old enough to know that someone somewhere has done this before.

I didn’t look forward to installing the sway bar drop links with Whiteline polyU bushing. It can be a bit of a struggle getting the drop link onto the sway bar. Mind you, Chris at T3 Techiniques makes it look easy in his video. By the way, T3 Technique is a place to buy polyurethane bushings and other suspension parts.

http://www.youtube.com/watch?v=7oXY68F8Uwo

I had thought about the notion of cutting the knob end off the sway bar then drill and tap a hole so a thick washer could be attached to replace the knob. But I didn’t like that idea for a few reasons.

So what I did do was this, I welded a 3/8″ stainless steel bolt to the end of the sway bar. Well I should say sploodge welded the bolt on, not pretty.

So what eh? Well now I made a bullet shaped tool, tapped for the 3/8″ bolt on the blunt end and tapped for 1/2 NC on the pointy end.

Some tubular spacers, lube, and a nut and the bushing ( already fully seated in the drop link by squeezing the two together in a vise) and hey presto, the bushing and link can be easily pushed on to the sway bar. Hey don’t rely on this pic for correct orientation of the sway bar bend to the sway bar, I was just doing a test run and didn’t take care. I did get it right in the final assembly… I think 🙂

i made a Delrin cap to fit over the exposed bolt. Tidies things up and may help to prevent the drop link coming off the end of the sway bar. This has happend with the softer urethane Powerflex bushings, maybe not as likely with the harder Whiteline bushings I have used, but hey, it’s another justification for this mod.

And of course I scraped the heck out of the paint on the sway bar installing it on the van.

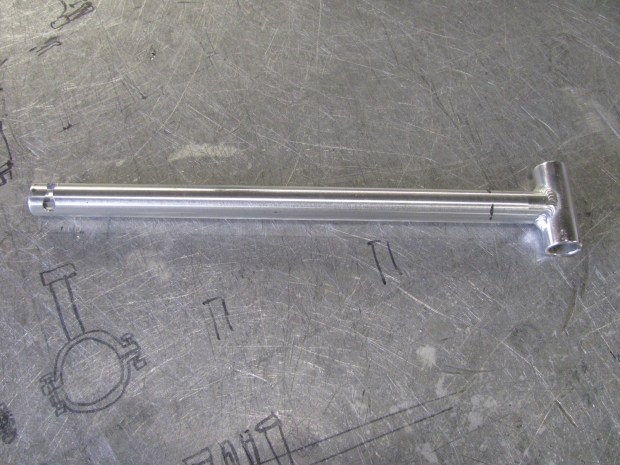

I guess I should show hey finished drop links. I had machined them a while back, 3/4″ (19 mm) stainless rod and heavy walled ( sorry I forget the wall thickness) tubing which had ID of 1 1/2″ (38mm) very close to to the stock link. Threaded the end M12X1.5, and a section approximately 17mm in diameter where it passes through the drop link bushings. No spacer in this set up, we’ll see how that works out, but is not an original idea.

I guess I should show hey finished drop links. I had machined them a while back, 3/4″ (19 mm) stainless rod and heavy walled ( sorry I forget the wall thickness) tubing which had ID of 1 1/2″ (38mm) very close to to the stock link. Threaded the end M12X1.5, and a section approximately 17mm in diameter where it passes through the drop link bushings. No spacer in this set up, we’ll see how that works out, but is not an original idea.

I bent them on a friend’s press using a quickly made set up that does leave some dimples in the bar. I think I took about 8 tons of force to bend them. I was shooting for 4 degree bend, but I went a degree or so more. I don’t think that will be a problem.

I cut them to length and ground a chisel point on the end. One root pass, then two straddling passes of weld, then I washed over with the torch. I got a bit of under cut on the rod, I could have done better but it will be strong enough. Notice the pattern on the ring portion, patented “Chattr-Mastr” finish on the bevel.

I used the cup washers I made a while back, but welded on a smaller diameter flat washer to the should of the drop link as I was worried that the enlarged hole of the cup washer would get pressed over the shoulder under hard use in the van. I think you might spot that washer in the pic of the sway bar install. I’m happy with these drop links, maybe not in the same league as Burley Motorsport’s, but ok for an amateur.

And another thing, with the bolt welded to the bar it is possible to make some little adapter so one could use a puller to remove the drop link from the bar easily. Ok, that’s a pretty weak advantage of this modification but I’m trying to find other reasons to account for the time and effort.

Vanagon – frustrating sidetrack

Posted by albell in vanagon, vanagon mods on April 19, 2015

Had a really frustrating week, seemed as though everything I touched went sideways. Most annoying was trying to eliminate vibrations in my swing away tire carrier. The latch pulls the swing away tight to the bumper assembly and I am pleased with how that finally worked out, but I don’t like the small amplitude vibration I get on the holder when the tire is attached. I think I am going to weld on a stiffening gusset to the upright and see if that will stiffen things up.

I bought a cheap rod bender from Princess Auto, this one here. It was on sale for 79 bucks. It works ok for what it is, and I thought instead of just bending random shapes while I try it out I would actually make something “useful”.

Well, I tried making a tail light protector and I soon realized that you REALLY NEED TO MAKE A JIG!

I’m showing you the result as a warning, think things out before you start merrily bending stock 🙂

The the tricky part was locating the little stand-offs accurately on the screw holes in the tail light. It’s obvious that the tail light is thicker at the top, but it also has subtle curves laterally and I was trying to match those curves and that made placing the little hollow studs for the mounting screws maddeningly difficult. You can see the nasty welds at those studs, result of tacking, checking, cutting, tacking, checking, cutting…

You really do need a jig.

And I think the guard would look a whole lot better if the vertical cross wires were not welded on top of the horizontal wire but welded to the middle of the section. I’m not going to try another until I make a jig, but even assuming I pop one off without pulling out my hair, these would be fussy and expensive Vanagon jewellery.

Vanagon – Simon feels small

Friend Simon traveling this last week, parked beside white van at Hood River Oregon.

Vanagon – attempts at making cup washers

Posted by albell in vanagon, vanagon mods on April 6, 2015

Not quite an unqualified success, but not a complete failure, I’ll settle for that. One of my sway bar drop links broke again and instead of the kind of repair I did previously , I decided to make new ones from stainless and beefier stock. I’ll detail that build when I have them welded up and bent. But I needed new cup washers and rather than buy them ( aren’t they around 13 bucks each?) I thought I’d have a go at making some from 2″ stainless washers. Here are my results.

First I tried pressing a ball bearing into the washer with a socket as a back up. You see on this test washer that it doesn’t make a good profile.

And on the 2″ washer.

So then I tried a different approach. Pretty self explanatory.

Useda friend’s press,applied between 10 and 15 tons of pressure. I also tried both ends of the male die, but the result wasn’t that great.

So I tried again. A quickly made female die with a rough profile of the shape I wanted, and a not very close match on the male.

Back to the press and…

Well not great either, but I’m going to stop. I’d didnt do any research on how one should make dies for this purpose, i bet I am missing something quite obvious

The end of my unfinished drop link.

And with polyurethane bushings and the new washers. Hey, note that I have ground a rough radius on the inboard side of the bushings. This helps them fit into the recess on the lower control arm. No’ they aren’t quite that same as the stock washers. The stock washers have a larger un curved area and turn up more quickly at the edges. But I figure when the bushings are compressed when installed, the washers will make enough contact and still allow some lateral movement of the drop link.

Vanagon – rear bumper, swing away tire carrier latch

Posted by albell in vanagon, vanagon mods on April 3, 2015

As I’m now using geological time scale in describing the progress on my rear bumper build, this latest update comes very quickly after the back up light install.

I needed to make a latch that would secure the swing away carrier tightly, but yet be reasonable easy and quick to use. I tried four designs, my designs, conclusively crappy designs. This, my fifth attempt would be my last, next stop would be buying a de staco type draw latch.

I still had the Delrin cone and socket arrangement that was for my first design. The cone and socket does work well to locate the arm to the steel back stop that is welded to the bumper subframe. So I kept that and made a draw latch.

Reinventing the wheel.

But I learned a bit while doing it. It’s interesting how the effective lever arm changes on an offset hole draw mechanism like this. The pivot points, effective distance, changes from about 3/4″ when draw hole ninety degrees from the pivot to zero when draw pivot are inline. This gives great mechanical advantage when closing the latch, and the over centre part helps keep the latch closed.

I occurs to me that describing all this is a bit of a mug’s game. Maybe some of you think that I should have bought a latch and be done with it, a very valid point. Some of you are probably not very interested in some damn latch – just show the finished project, an equally valid point. And some might think I’m boasting about making the darned thing. It’s that last suggestion that bothers me.

You could make the case that writing any kind of blog is a tad egotistical. But believe me, the best thing about writing this kind of blog is finding out that you might have helped or at least nudged someone in the right direction.

Ok, enough blether.

I made the handle from 1″ thick aluminum. Part of some offcuts from the water jet guy. Had a nice curve and I continued the curve ti make the working end. Drilled holes for the pivots, slotted the end for the fixed pIvot ( that attached to a little bracket that was made from some 1/8″ thick stainless, mounted to the carrier with 1/4-20 bolts, helicoil inserts in the carrier).

I turned and milled a bit of stainless to hold the bail ( the moving pivot) and the bail is a bit of 5/16″ stainless rod that I bent into a U shape and threaded the ends.

I used some 1/8″ stainless plate and 1/4″ rod to make the little catch on the backstop that hooks onto the bail.

I was worried that there wouldn’t be enough give in the mechanism, so I stuck in some hard rubber washers under the nuts on the bail. You can see them in the first two pics. I found that there was enough flex in the backstop latch that the washers weren’t needed.

Ok, the handle and fixed pivot.

And mounted on the bumper.

See how I have to use some spacers to match the thIckness of the cone and socket bases to give the upright of the carrier a bigger surface to pull against? I’ll try and make a nicer version of the spacers, maybe one piece.

I have to make a plug for that hole. Also a fair bit of grinding and sanding to be done before painting. But hey, I’m making some headway.

Oh, and I have yet to weld on some sort of tab thing on the end of the handle so I can pin it to that curved tube as a safety or even a lock.

Vanagon – 85 Doka

Ive been doing little work on my neighbour’s ’85 Doka recently. It was originally white but he did a quick paint job which I think looks very good. The colour scheme works well. He also lowered it and put on some 18″ wheels.

I pulled the dash and heater box to replace the motor and re-foam the heater box flaps. I don’t think the dash had been removed before but it all went easily, even the heater box bolts that go through the front body wall and are exposed behind the grill. Often those bolts get rusty and are a bear to remove.

The heater core was filthy but no leaks.

As a replacement blower motor I used a Vanagon A/C blower. The housing is identical and it fits in perfectly. The actual motor has, to my eyes at least, an improved end bearing/bushing. not as exposed as the stock motor. I added a little lube and then JB welded a bottle cap to cover. Kinda hillbilly, but it stuck on there well.

The other difference with the A/C motor are the electrical connections, but it is easy enough to splice it in. I know in the pic, the wiring looks a little sloppy.

As expected, the foam on the heater box was pretty well all degraded. For a replacement I used truck canopy foam tape found at local RV store. Its open cell foam with a clear plastic face on one side and adhesive on the other. The important thing, well I think so, with the foam is that it should be very compliant. The flaps have to be able to close with little effort. The plastic face on this particular tape reduced that compliance, but I discovered the face could be peeled off. On some of the flaps its a bit tricky to get the sticky backed foam in place, but you can remove one of the flap sets to make that easier. Oh, forgot to say, the heater box had not been touched before this so I had to cut off the tabs that are plastic welded together along the split seam. This time I used an angle grinder with a 60 grit flap wheel (blending disk) to grind the tabs off. That worked the best of all the methods I’ve tried over the years. There were a few metal clips on the seam, strange that wasn’t the full compliment to use when fitting the blower back together. But I had some in my parts stash.

But you’re not reading this, I hope, for a blow by blow description of the heater box R&R.

Old motor in the right, A/C on the left.

A/C motor, note end bushing.

And the old blower. It is tempting to say the end bushing is more exposed.

And the bottle cap glued on 🙂

Foam tape with the plastic faced peeled off.

Dash back in place. Stereo had unit still out, the PO had done a really poor job of wiring, I had to come back a week later and redo do all of it.

Vanagon – rear drum brake helpful image

I found this image on the Samba a while back, I think it was posted by Alaric. It’s a very helpful image to have around when you are working on the rear drum brakes. I know I get confused what goes where and in what orientation.

Vanagon – rear table socket

Posted by albell in vanagon, vanagon mods on March 24, 2015

Ok, this is not the most astounding modification of a westy, but it is a nice little touch. I was looking at the hole in the cabinet where the rear table leg goes in and I thought that it should have some sort of trim on it. I had the distinct idea that later westies did have trim there, but I found out later that my friend’s ’91 westy doesn’t. So I have no idea how the thought got into my addled brain.

I made a trim ring from some black Delrin.

Ok, that’s all well and good, but fellow Vanagon mailing list member Stuart wondered if I could make a leaking off plug for the hole as he doesn’t use the rear table. I had a little bit of some sort of South American hardwood that I had been hoarding for, I can’t belive it, 30 years, and it seemed like the right stuff to use for the plug. Stuart thinks it’s Cocobolo, and it might well be.

Vanagon – behind the rear seat sliding cover

For educational purposes…pdf file

Vanagon – quick throttle body re-bush

Posted by albell in vanagon, vanagon mods on September 13, 2014

A few years ago i tried re-bushing a spare throttle body using Delrin as the bushing material. I couldn’t get the throttle action smooth, it seemed as if the Delrin had a stiction property that I just couldn’t over come either by sizing the bushing or lubricating. So I laid the project aside and forgot about it.

Then this last summer I noticed some play in the shaft of the throttle body installed in the van. There was enough play to make adjustment of the throttle position switch very fussy. So i though back on my previous experiment and I thought I’d try making bushings again, but this time out of HDPE.

First let’s go back to my spare throttle body, the one I re-bushed with Delrin. I have a blog post here showing it before I started screwing around. I even went as far as cleaning up the wear marks in the bore and making a new butterfly plate to compensate for the now enlarged bore.

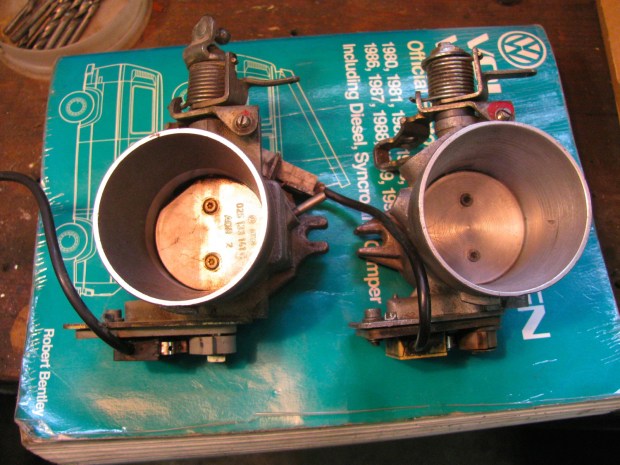

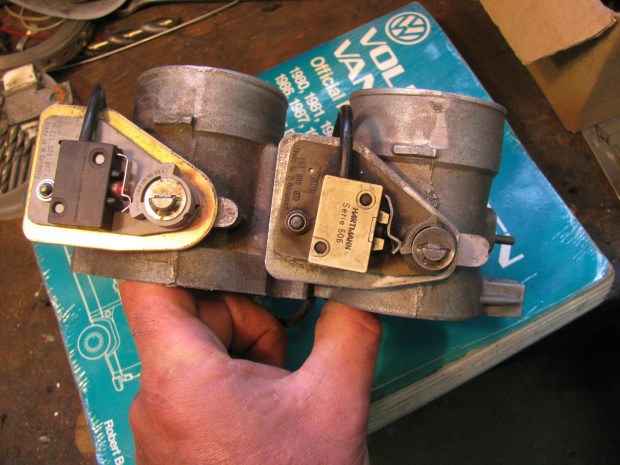

See the Delrin bushing?

And on the other side, the throttle position switch side.

My daily driver one on the left, the re-furbed one on the right.

Not the larger cam on the one on the left. This is the newer, revised throttle position switch system.

It appears like a lot of space around the butterfly, but it really isn’t that bad. I can’t recall the gap size (I measure with wire).

It kinda looked ok to me.

The dried up seal on one side.

And the other.

Wear in the bore from the butterfly.

I decided to leave bore and the butterfly untouched. I chucked up a hunk of polyE and turned and reamed a couple of bushings.

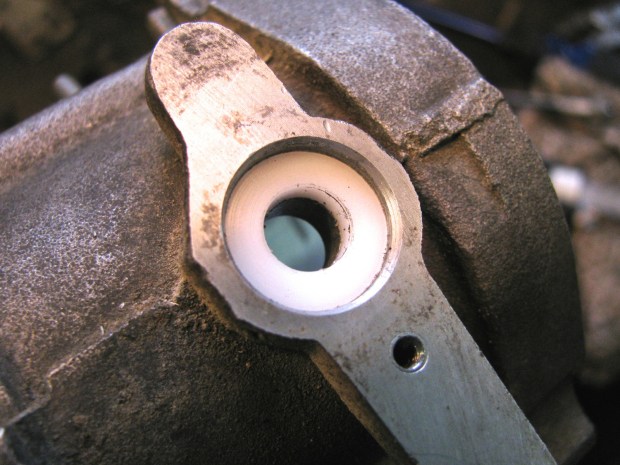

Recessed on the throttle position switch side.Why? because the switch plate has little locating tabs that fit into the hole.

Pretty well flush on the other side.

Gosh, i can’t recall for sure the butterfly shaft diameter, maybe it was 8 mm, yeah I think so. I do have an 8mm reamer. Anyhow, I did think about bearings instead of bushings. But the bearings I had on hand had a larger OD and that would have meant taking the throttle body to work to use the milling machine; tedious set up and then a boring head.

Assembled. I have to say the action of the butterfly is smooth as silk, much better than the Delrin. Come to think about, I wonder if I reamed the bushings the last time?

The throttle position switch now is easier to set, there is no wobble in the butterfly shaft.

Vanagon – front suspension bushing work

Posted by albell in syncro specific repairs, vanagon, vanagon mods on September 12, 2014

About a month ago i replaced a few bushings on the front suspension of my ’86 syncro. They were they sway bar to body bushings, the sway bar drop link to control arm bushings, and the steering rack bushings. I replaced them with Whiteline polyurethane bushing from Chris at T3 Technique. I can whole heartedly endorse Chris for his great customer service and products.

So first the easiest, the sway bar to body mount bushings. Here is a pic of the one of the original rubber bushings.

A couple of 13 mm head nuts and bolts and the mounting bracket comes off. Note the spacer used in the syncro bracket.

New bushing comes in pairs, and with a sachet of grease. Grease is important in polyU bushings. They do have a reputation that they squeak, so you must grease them up with s low wash out grease. T3 techniques sells a couple of greases, and I bought one of them, Accrolube. I didn’t know when i ordered that the Whiteline bushing come with their own grease. So you might see in the pics that i have used both the black grease from Whiteline, and the blue Accrolube. Note that the Whiteline package has instructions on where to apply the grease, important for bushings that undergo twisting motions.

Pretty easy install.

Next up are the drop link end bushings. You can read all about what I had done to the drop links a few years ago here and here

So far all the work has been done with van on the ground, but after I removed the nut at the end of the drop link I jacked the van up so that the drop link pulled up and out of the lower control arm. Be careful or course, block the van, support it etc etc. the drop link will come up out of the hole and then you can pull the sleeve and the topside bushing off. Look at that old bushing, that old home made bushing 🙂

The homemade sleeve is holding up fine. Interesting grease residue marks in the middle, showing the edges of the bushings? also note the shape of the new bushing. It is flat one one side, domed on the other. The domed side goes into the control arm recess, the flat side faces the dished washer. The flat side really should be slightly domed or at least bevelled, I think. Chris agrees. I modified the bushings on the other side, ground a bevel on them, but of course didn’t take a pic. I think the bevel roughly matching the curve of the dished washer would allow a little more articulation in the joint.

Now the install of the new bushings. Dished washer on the drop link first, convex side facing bushing, then a bushing with sleeve installed in it and the drop link inserted in the control arm. van lowered off the blocks so the drop link is pushed in the control arm. but the new bushing is tight and not much of the other end sticks out. So even with van fully lowered, wheel on the ground, not enough drop link is exposed to get the other bushing installed.

So i rigged up a ratchet strap and pulled the drop link down. Also disconnected the sway bar to body bracket. Even then it was a bear to get the lower bushing installed.

I certainly couldn’t get my dished washer installed so I pulled the bushing in as tight i could with a plain flat washer and the nut. I would do the nut up tight then remove it, put on the dished washer and try the nut…. just wouldn’t catch the threads. My home made stainless washer was too thick.

So i turned a recess in the washer and after a bit of a struggle and a lot of cursing, i got the washer and nut on. The other side was a tad easier with the modified bushing. But this part of the job took me a couple of hours.

Now on to the steering rack bushings. There are four of them, upper and lower, left and right. Here you can see the lower on the right hand side. The bolt goes throughout the bushing and frame member and there is a stover type nut on the end. I would advise you to soak the nut side with penetrating oil a couple of days before you do this job, there is a fair bit of exposed thread on the bolt and they can be rusty.

I started by loosening all four bolts, but not all the way. Then had at the lower left side bushing. I removed that bolt, oh careful, there is s slim washer under the nut. The with a slim small pry bar i pushed the bushing out from behind. Remarkably it came out quite easily. On a couple i grabbed the bushing with needle nosed vice grips to ease its passage.

They seem to be in pretty good shape.

The new bushings are two piece with supplied sleeve.

Pretty easy to install. I did one at a time but didn’t tighten up until all installed.

Yeah, supervisor was checking in.

Now on the driver’s side the steering rod (from steering gear box to steering rack) prevents the steering rack from being pried forward enough to both pry out the old bushings and install the new bushings. I disconnected the coupling at the forward end of the rod and loosened the slimed coupling at the u-joint in the rod. It was only later, looking at the pics did I notice the cracks in the rubber coupling, sheesh, another thing to replace.

Wrench access on the driver’s side is a bit restricted, so it take a little longer. But these bushing took less time to install than the drop link bushings.

So the verdict? I could really notice the steering response improvement, especially at highway speeds. I’d recommend the rack bushings even if your existing bushings are in good shape.

Vanagon – body insulation idea

Posted by albell in vanagon, vanagon mods on September 11, 2014

Saw this on the samba, i think it was syncroghia that posted in his thread about adding high top to his 16″ syncro. I thought it was a good idea so i gave it a go on the rear hatch.

It is just water pipe insulation, I think its foam polyethylene, cut to length and wedged into the cavity. Now that summer’s over one might find pool noodles going cheap and I think they would do too.

I like this because it is cheap and fast to install. No gluing and I don’t think it will trap moisture against the metal.

I stuck on a bit of peel and stick roofing stuff to dampen panel noise. My van had some factory applied bits already there. Remember this is a converted 7 passenger tin top. I don’t think we sties have the factory sound proofing in the back hatch, but they do have the dreaded fiberglass batting.

And just because i had some, i pushed in some 3/8″ thick closed cell foam. Left over pipe insulation stuck on lip of cut out.

I liked how it went in, I think I’ll do more of it.

Vanagon – sliding door rollers replacement

Posted by albell in vanagon, vanagon mods on September 8, 2014

About 2 months and no blog posts, sheesh, the next few posts will be playing catch up.

The 85 model year and newer vanagons have a much improved sliding door. Easier operating and a bit quieter than the old style but I thought it could be even better. I had tried UHMW polyethylene tape on the surfaces that the rollers ran on would be the ticket, blog post about that here. But the tape wore out after a year and a bit.

So i thought about a plastic version of the steel rollers. I made a quick and dirty prototype from some Delrin to try on the middle track (the track under the cover on the side of the van).

Not quite an exact copy and a bit out of focus. Here it is installed.

Verdict? Well it is quieter than the steel roller and it rolls just as easily. But with that track silenced a little, now I could hear the lower track roller noise. So some time later I set about making another middle slider roller and seeing what I could do about the lower track roller.

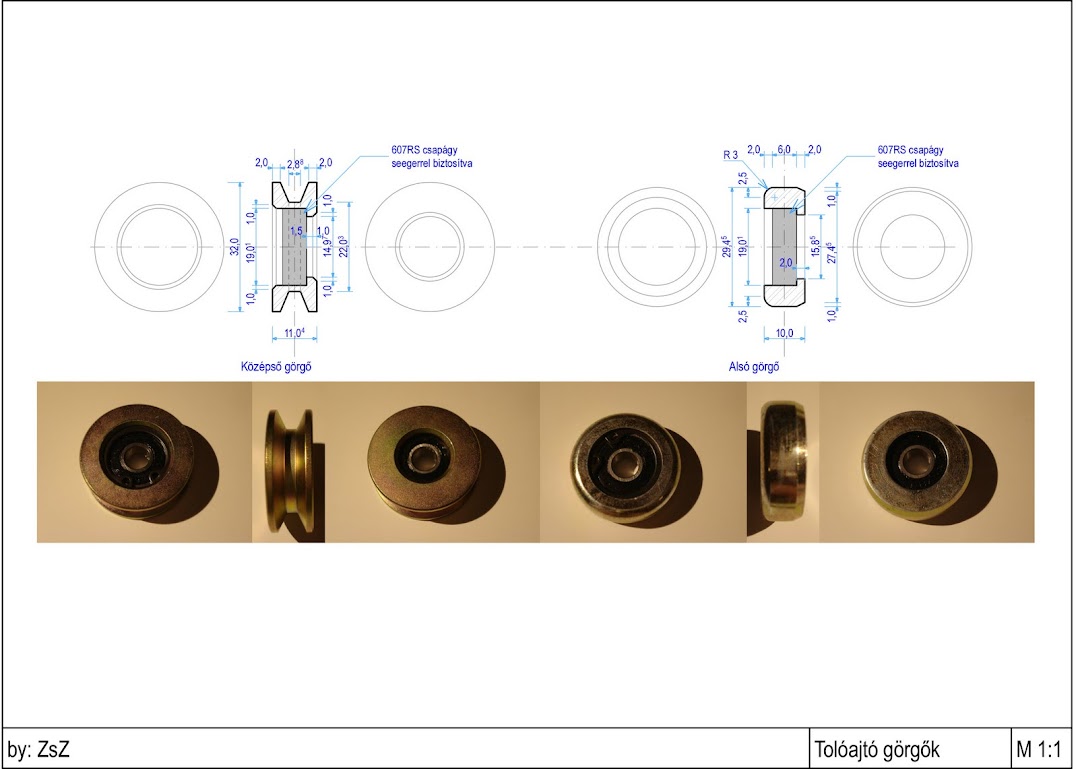

Middle roller, more care taken. Oh, I should mention that the bearing used in the roller is a 607RS. Dimensions are 19mm OD, 7mm ID, 6 mm thick, and rubber shield.

I took the sliding door right off as I was working on the lower roller at the same time. Here is the stock steel roller.

And my Delrin version installed. See the 2 other bearing above the plastic roller? They run in a vertical channel above the rail the main roller runs on. I didn’t do anything with them, but i probably should have thought about it.

I was going to make a lower track roller from scratch but I found a plastic roller in my junk pile. I think it was from a hanging door, but I can’t remember anything more about it. I wish I did because it is very close to the stock roller dimensions. I just had to reduce the OD by a few millimetres and replace the bearing with a 607RS. It originally had a 6mm ID bearing. The circlip retaining the bearing was a real bear to remove and I accidentally broke a little of the plastic.

here is the stock steel roller. The roller is on a post on the lower assembly , secured by a circlip. The plastic shield can be pried off and the clip removed and the roller pulled from the shaft.

This is not a roller with a pressed in bearing, the bearing and the roller are all one piece.

Has a rubber shield on the inside, the bracket side, face.

Comparison of the stock roller and the hanging door roller. Both have somewhat similar profiles. Close enough for me anyway. But as I mentioned before, I had to turn down the OD of the plastic roller.

Plastic roller with new bearing installed

And showing where I broke the darned thing.

And there it is installed on the door bracket.

So did it make a difference? Yes, it did. Again quieter and smoother. The door still is not as quiet as I would like and I think some of the noise is coming from those vertical bearings on the middle slider, the pair I should have paid more attention to.

You know, this is the kind of project that 99.9% of people would look at and shake their heads, mutter “get a life” and then wander off to chat with someone else. It is only when i sit down and write this post does that realization sink in.

Crikey, forgot to add an important thing… to thank “ZsZ” for posting measured drawings on this Samba thread. I’ll be cheeky and link directly to the drawing.

Trip – turned out to be more of the same

We were planning on exploring some new areas when we left late Sunday afternoon but were thwarted by closed gate on the access road. Where there is active logging the contractor usually restricts access to the area by locking a hefty steel gate across the road or even just a steel cable with signage. I think they do that mainly to reduce chances of vandalism or theft of machinery or equipment left on site during non working days. So we headed up to one of our fall back view point spots while there was still heat in the day and we could sit back and enjoy the view and some beverages.

So there we were, again.

Bridging ladder used to level the van. My van is a rolling advertisement for my slowness in finishing things. Sliding door skin repair, rear bumper build (well it is getting closer), still no tires for the 15″ alloys I bought a while back.

Took a walk, into newly logged area. I was taken by this cloud on the hill.

And took a bunch of pics for a pano. If you click on image it comes up in new tab/window, at my default image size of 1500 pixel max dimension. You might be able to make out the beach at Port Renfrew.

Then suddenly it seemed like someone turned on the smoke machine to film some post apocalyptic movie.

And almost as quickly turned it off.

You know, i never get tired of the view looking over to Washington, summer sunset. You notice the orange haze? Could be from a forest fire somewhere. A couple of summers ago we had amazing sunsets when camping in same general area that were due to forest fires in Russia. Hard to believe eh?

Next morning I got up early and took some more pics to stitch.

We left at about 0930 and made a few exploratory trips up roads like this. But we didn’t find a good spot to camp.

So it was a fall back to Loup Creek. It is pretty isolated, I don’t think many would make the effort over the moderately rough and slightly overgrown road just to be able to sit on a bridge. No, I’m not picking my nose.

The creek is beautiful, but quite cold. We hiked around, exploring a few km upstream and a little ways downstream. Here are a couple of pics of a little feeder stream, posted to point out a couple of things. First is that I find it really hard to take a pic of theses streams during mid-day. The river rock reflects light, the shadows and greenery suck the light up. I think i would have to set the camera on a tripod and take a series of pics with varying exposures/aperture and sam them together for an HDR image.

Second is that these short steep streams on the west coast of the island vary in flow tremendously.

You’ll find debris high up on the rocks or the bank that was deposited during floods.

All that white rock would be underwater during winter spate.

Supper time on the bridge. Chairs now on south end to catch the sun.

Eco-Que being used. Marinated chicken on flat steel skewers. Still haven’t used the grill surface of the Eco-Que. Yeah, just nine briquets.

Lid on to finish cooking.

Had this canvas bucket for years, US Army issue, one of the most useful accessories.

Next day we explored more, sunbathed more, read more, drank more, ate more, dunked in the frigid creek more, and then drove home in the late afternoon, early evening. Van ran like a champ, fridge worked from when it was lit at leaving on trip to when we got home. Garmin Glo and iPad mini remain a superb navigation combo – I should do a post on the software I use.

Vanagon – syncro clutch slave cylinder replacement adventure

Posted by albell in syncro, syncro specific repairs, vanagon on June 21, 2014

Seems to be a real busy time of the year for me, just the time to put a new slave cylinder into the old syncro. It had been leaking for a few weeks, but it still worked the clutch. I procrastinated replacing it until I felt like hurting myself.

I’ve swapped in a slave cylinder a couple of times on a 2wd vanagon, I4 powered ones at that, and it was not that bad. But the stock motor in the syncro makes access to the bolts holding the slave to the bracket really painful. The rear most bolt is somewhat accessible front he engine compartment but the nut for that bolt is pretty well hidden by the bracket. A good fix for that is to weld that nut to the bracket so you only have to deal with the bolt and no need to hold the nut. The front bolt is somewhat easy to access, from under the van. I tried to get those bolts off, but I couldn’t. I even bent a wrench to get it in there, but no luck. I had heard that some folk take the bracket and cylinder off as a unit and that means taking the actuating arm off the shaft that goes in the bell housing (and moves the throwout bearing). There is a cir clip on the end of the shaft and theoretically, on a brand new van, when the clip is removed you can slide the arm off the shaft. I don’t see how you can do that easily on any van that has seen any kind of use. The arm is on there but good.

I had a spare arm (and shaft) so I decided to grind the arm off. I used a steel burr on a die grinder. Yes I chewed up the shaft, I got sloppy. But I didn’t do enough damage to make the replacement arm a poor fit, still went on tight.

I tagged the bracket too.

The arm.

Now it was just a case of removing the 13mm head bolt on the bracket support strut and the 17mm bolt holding the bracket to the bell housing. Then you can ease the assembly down and let it hang by the hydraulic line. Great thing here is that the syncro has a flexible nylon line to the slave (and banjo bolt) rather than the steel line of the 2wd.

I had the new, FTE brand, cylinder already to go, bolted to a spare bracket. A bracket from a diesel vanagon… yes, you know what’s coming.

I had welded the two nuts to the bracket, here is a pic of the front nut. Yes, you know what’s coming.

Quick with the swap over and now bleeding with the cylinder hanging.

And up it goes into position… except I forgot the support arm is held to the bracket by that front nut which I had welded on. Doh, what a bonehead, ok off it comes with the zip disk. Right, up again with support arm attached…except it didn’t fit. The support arm would not line up with the bolt hole in the transmission. Son of a bitch. Out it comes, let’s compare with the old bracket.

Gee, whaddya know? They are different. It takes a special kind of bonehead to assume a 2wd diesel vanagon bracket would be the same as a wax syncro bracket. I am that special bonehead.

And, to add insult to injury, after cleaning off the muck from the bracket I could see someone had brazed on the rear nut and had brazed on the nut to the support bracket. So i could have removed the slave by itself after all. Well, no, not really. The bolts were in there real tight. Even with the bracket held in a vise I had to grunt with the spanner to remove the bolts.

Righty oh then, back to the van to install new slave and old bracket combo. All went well, replacement arm on shaft, cir clip in place, slave bled. I tried the clutch pedal. The friggin pedal stopped hard about 2″ above where it should stop, no clutch activation. What the heck was going on?

The arm would move when the pedal was depressed, but only a little way before the pedal felt like it was hitting metal. I pulled the push rod from the slave and compared it with the one from the old slave, it had a longer effective length. New push rod at the bottom of the pic.

With the rod removed the clutch pedal would not move, with the shorter old rod the clutch pedal would move down a bit, with no rod and the bleed screw open on the slave the pedal would press down full range. Can you guess what was up? I couldn’t at that point. I talked to Dave the mechanic, we both were stumped but were leaning to an internal problem, perhaps the throwout bearing retaining springs had come adrift. Looked like a tranny pull. I was so desperate that I looked on the Samba and found something interesting, here is the thread. Now I had some hope, so I quickly made a bit of an extension using the old rod (I removed what remained of the plastic that was inside the metal cup end) and some polyethylene.

I made a hole, stepped hole, to mimic a socket to engage the ball on the lever arm. I installed it and yes, more pedal travel. Not quite enough so a made another using some Delrin rod. Here it is. BTW, it is a press fit into the metal socket.

And, yes, success. Clutch works just like it used to, perfectly. Man, I was relieved. The modified pushrod had overall length of 112mm, socket in the Delrin was 4-6mm deep giving an effective rod length of 106-108mm. That’s 18-20mm longer than the new FTE push rod.

So what the heck was going on with the new slave? As I didn’t want to take it out and measure I can only guess that the new slave had a shorter piston stroke than the old one. And even with a longer push rod it was not enough to fully activate the clutch. And before you ask, I did have the slave cylinder properly installed in the bracket. I wonder if the syncro bracket locates the slave higher from the arm than the 2wd bracket?

Vanagon – new wheels and tire fitment

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on May 10, 2014

Too long i have suffered the jibes from fellow syncro owners about the teeny stock wheels and tires I use. Finally I found some wheels that might let me join the real mens club. They aren’t my first choice but the size, price, and offset were all right. They are 15×7 Mercedes 15 hole alloys from an early ’90’s 380SL. The offset is 25 which I kinda like, I wanted good clearance from tire to suspension components. Another good thing about these particular wheels is the thickness of the casting where the lug stud goes through. In this case it is only 11mm, some can be as thick as 44mm. I would have to install longer studs for any wheel thicker than 11mm and that was something i did not want to do (its a pain to do the front studs on a syncro). This wheel thickness will come up later.

Anyhoo, I’m not going to go into all the tire choices in this post. Im just going to show you what I did today to see if one particular tire would fit. The tire in question is a Yokohama Geolander GL AT-S 225/70 15. They have I think a load rating of 100, which is my, probably flexible, lower limit.

Here’s one bolted up. I sanded this one a bit (they all need painting) to try out a primer. The wheels have to have the stud holes drilled out to fit on the 14mm Vanagon studs. They were originally drilled to accept 12mm studs. You also have to get new lug nuts, the small seat ball type as opposed th the conical Vanagon variety. I got the hardware from T3 Techniques, and I also have received a lot of great advice from the owner Chris over the years.

Here is the small ball seat lug nut from T3 Techniques.

The trial fit was done on the rear wheel for a few reasons. First, the rears have the shortest stud projection, just flush with the stock steel wheels. With the alloys I got about 6.5 turns of the nut to hand tight. Now with the thread pitch being 14X1.5 mm that means the nut goes on 9.75mm. I would have liked more, 14mm would be the same as with the steel wheels. I don’t know if this amount of thread engagement is not sufficient, anyone have any thoughts?

edit: 9.3 turns would give me 14mm of thread engagement. That would be grand, but there is a German notice of requiring 6.4 turns minimum. So what to do? I am leaning towards longer studs for the rear. The front studs might be ok, there is a couple of threads exposed with the stock steel wheel, unlike the flush situation on the rears.

The second reason to check fitment on the rear wheels is to determine if rim and tire combo clears the trailing arm. I made a rough template of the tire profile from published data. What I am not 100% sure about is the sidewall height. I initially made the template so that the sidewall height was measured from the lip of the rim. When i held the template up to the wheel it interfered quite a bit with the trial arm. I thought this strange as I am sure I have heard of this size tire fitting the stock trailing arm, even on rims with higher offset. So i trimmed the template so that the sidewall height includes the tire bead section.

Not a great picture but you can see the notches I cut and you can see there is not only about 1/4″ of clearance between template and the pinch weld seam on the trailing arm. My template does not have radiuses corners so that might exaggerate things a bit.

I don’t know if this close up illustrates the clearance any better.

I’m reconsidering this tire size based on this quick and dirty measurement.

The other worry is that with a wide tire and a 25 mm offset rim there might be interference with the sliding door. Well no worries there, it clears with about 10mm to spare (close to my paper calculation).

I’m going to have to pour over the tire choices once more. Please, don’t mention Nokians, I know, I know.

During all this my friend was giving me skeptical looks.

Vanagon – stock tire carrier replacement idea

Posted by albell in syncro, vanagon, vanagon mods on May 10, 2014

I should have spent the time finishing the rear bumper build but over the last two days I grabbed a couple of hours alone in the shop and tried out an idea.

When I do get the rear tire carrier built, and I am almost there, I will be moving the spare from the front to the back. I guess I didn’t need to tell you that. The free space up front, what to use it for? Well I have that big assed AGM battery that I’m struggling to find a spot for. Why not put it up front? There are arguments pro and con for this idea, but I decided to have a go, at least a start.

There were three kinds of stock spare tire carriers. The tray type, in two sizes, and a cage type that you don’t see that often here in North America. Here’s a pic.

I like that carrier and i like Tigerbus’s take on it.

I can’t make anything as nice as that, but here goes with my attempt.

I’m using aluminum scraps again. Schedule 40 1 1/4″ 6061 pipe (OD about 1.66″, wall thickness 0.140″), some Shmoo shaped 1/2″ 6061 plate that were left overs from a water jet cut, a bit of 3/8″ plate that was cut out of a boat hull, and some 1″ x 2″ box section 6061.

The Shmoos were welded onto the ends of the pipe, attachment points to match up with the hinges on the van spore tire tray.

And at the other end the pipes notched and welded to the box section at a bit of an angle so it fits up against the back of the bumper where the stock tire tray bolts up.

Trial fitting.

More or less fits.

The rather skanky bit of hull.

Yeah, the other side is painted. That made welding a bit of a chore.

Tacked in place.

I did a full weld-out on the unpainted side. I welded it hard and fast so that the paint didn’t fume too much. I should have used the wire feed welder instead of TIG.

Now at the front, I will be adding more stuff there, coming up in front of the bumper similar to the Tigerbus version. Im also going to add some side pieces that will angle up to meet the frame rails on the van. These bits will add side protection and will be additional points of attachment to the van. I do worry about the thing falling off with that big battery.

Vanagon – bridging ladder

it’s been a while since i posted anything, busy at work and at home. I have some Vanagon stuff to post and I’ll get on it as I can.

This post is about a bit of fiberglas grating I picked up to use as a bridging ladder. I’ve been looking for off cuts of the is material for quite a while now and last week I finally found some. The source is interesting but I really can’t say where. This kind of bridging ladder is commonly used in the UK and Europe but I don’t see it being used much over here in Canada. Here is a link to a UK source.

What I found was slightly different as what you see on that link, it has extra webbing on one surface and a very coarse anti slip grit embedded on same surface. Also it had been partially cut, annoyingly so as it screwed up a neat division into two long usable pieces. And it is about 38mm thick, major grid size is about 1 1/4″ square. You have to love the mix of measurements.

I cut it it to get one good strip and gave it a test. You can see how it bends but doesn’t break.

They left over strip, still with the partial cut in it, was strong enough to make a ramp.

And the un cut section supports well.

I have to explain why i want something like this. On logging road spurs you often find water drainage trenches cut across the narrow road. Seems to be the norm nowadays instead of installing a culvert. The trenches can be deep and steep sloped, either by design or by the drainage water eroding the sides. Sometimes the shape of the trench makes a perfect tank, I mean, Vanagon trap. You only need a little help to get across and I think even one bridging ladder will do.

Vanagon – yet another bumper build update

Posted by albell in syncro, vanagon, vanagon mods on April 1, 2014

I got something done today on this never ending project. I bought some C channel steel (1″x2″, 3/16″ thick) to replace the stock bumper mounts. I cut them long enough so a third bolt can be used to secure, just like the stock VW trailer hitch set up, and just like the RMW bumper system. With those channels rough cut and inserted I was able to offer up the bumper to the van, fitting it to pretty well its final position.

I attached the unfinished swing away tire carrier.

And popped on a spare. I was worried that I had screwed up my measurements and the tire would cover part of the left rear light. But It clears it ok.

The bumper was not attached to the rails so it did tilt back a little. The tire carrier upright should be closer to the hatch.

And swung out, the tire clears the van.

Vanagon – jury rigged fix for deceased cat

Posted by albell in syncro specific repairs, vanagon, vanagon mods on March 28, 2014

This post might get me some guff, but please have patience, I will get a new cat. The catalytic converter on my van is old, very old. Recently I’ve suspected it really was a converter in name only. I took it off today and it was empty. All the rare earth metals and ceramic had blown out through my stainless muffler. Ok, so now what? I had the shell in my hands and I decided to do a little experiment before i hunted up a new cat.

I had this resonator muffler thingy hanging around the mess I call a workshop. It is a little longer than the cat but I thought I could slap it in place and see how it effects the sound of the exhaust. Ok, here goes..

The resonator, 2″ outlet/inlet. I scrounged a 3 bolt flange and cleaned it up on the lathe. Bored it out a tad so it would fit on the pipe.

You see? Pipe set into the flange.

And positioned not quite all the way through.

While I was at the lathe I necked down a nut to act as a threaded bung for the O2 sensor. Man, I just can’t recall the size of that nut right now.

Tacked the flange to the pipe.

Then a mostly autogenous weld inside.

If you squint you could imagine that hole was roundish.

Necked down nut pushed in hole.

And a bit of a heavy handed weld.

Two slits on the other end (tubing fits over the tubing inlet of the muffler. The slits will let the muffler clamp squeeze the assembly tight)

During installation my new lover was pestering me. For the last few weeks this goose has decided I am something special. I really don’t know what is going on with her.

I had to slide the muffler over a bit to get the resonator installed. It does look a bit funny, I admit. And did it change the exhaust sound? Yes it did, it is a bit quieter, with a hint of raspy with quick throttle off.

Vanagon – totally superfluous lantern holder

Posted by albell in vanagon, vanagon mods on March 24, 2014

This is the result of Felder Enterprises announcing a lantern holder made using a Bus Depot awning gutter clamp. I can’t let FE get ahead so before I got down to paying work I made my own version. It is based on a design I’ve seen on the web that uses PVC tubing and a PVC “T”. But I had some aluminum stock so I used that.

I milled a slot at one end to hold the lantern bail.

And a slot to go over the rain gutter.

And a bit of paint protection.

On the van.

And surprise, it clears the sliding door.

I have no pressing need for a lantern holder, I guess i was just in one of those moods this morning.

Addendum, 28/03/2014

Well it seems that i didn’t get the itch scratched, i made another hanger. This time from some scrap thin walled stainless tubing. Part of it was the end of a roll, so it had a little bend to it. I thought that might be interesting. I ground the welds out just to make it look a little sleeker. I don’t think it works as well as the aluminum version, the tubing is so thin that the slot that goes over the gutter spreads a little when weight applied to the hanger. But it might be strong enough, we’ll see.

h

Vanagon – swing away tire carrier – more on the latch

Posted by albell in vanagon, vanagon mods on February 20, 2014

Ok, I know this conical latch idea of mine is flakey but bear with me. I got some things tacked up today to see what was what. First is the upright that will hold the spare tire. In my last post I said how I had to make an adjustment to get the upright close, but not too close, to the back of the van. My solution was to cut and bend the upright to mirror the profile of the rear of the van. Here are some pics with the upright (not fully welded out yet) roughly in place. My swing away arm is just clamped to the stock bumper.

I think this might work.

Ok, on to the latch. I tacked welded a bit of U channel onto the upright and I also bored a hole for and tacked in the short section on alluvium tube that you saw in the previous post and that houses the female Delrin part of this cockamamy set up. Here is the latch assembly more or less assembled. But some notes of explanation needed. Of course the threaded rod has not been cut down to size yet, and that metal but you see right against the left most flange represents the back stop I have yet to weld to the bumper. the two flanges meeting (and I think I might slim them down a tad) are the male and female parts in tight congress.. on the right hand side of the box section upright you can just see a trimmed down nut on the threaded rod, the thread rod, then the hand wheel. See the collar in place inside the “cage”? I need to make a set screw for it. The collar does two things, keeps the hand wheel from falling out of the cage when it is unscrewed from the rod, and when the hand wheel is turned to unscrew from the rod the collar pressed against the cage and pushes the upright away from the back stop.

I really am not doing a good job of explaining this. You’ll have to wait for a video or something.

Face on view. Aren’t I a clever fellow making 5 holes in the hand wheel reflecting the five holes in the vanagon wheel? It’s this attention to useless details that distinguishes my crazy ideas from other crazy ideas. 🙂

(Here’s something educational. Click on the pic to bring it up in a new tab, then zoom in on the tack weld on the left side of the fully visible seam. You can just make out a hairline crack on the tack. This happens because the heat sink of the thick walled box section tubing draws heat away very quickly from the cooling puddle of the tack weld. To reduce the chance of this happening I should have warmed up the tubing, it was pretty well dead cold. )

Male and female separated. Time for a smoke.

I think I can weld out everything now, and trim down a few of the moving parts.

Update: 21/02/2014.

Dirk over on the IG16 syncro forum expressed some concern that the upright being made of aluminum would waggle back and forth like one of my dog’s tails. Any time a German engineer gives advice it behoves one to listen 🙂 . So today I welded up (not very well, i was rushing) the upright and tacked it to the swing arm, and I cut out a reinforcing piece to weld in (3/8″ thick 6061 stock). I am almost positive now that things will be wedding night stiff when finished.

Vanagon – swing away tire carrier latch – a start

Posted by albell in vanagon, vanagon mods on February 19, 2014

I’ve been amusing myself (!) by attempting to make a latch for the swing away tire carrier that’s going on my aluminum bumper. I have this almost unreasonable desire to make sure the horizontal arm of the carrier is fixed hard against a back stop on the bumper. I know other designs use an over the centre draw latch mechanism, and I am sure they work well. But I got in my head that I wanted to try another approach.

The back stop mentioned will be a sturdy bit of aluminum plate welded vertically to the forward top edge of the bumper. Something like a 4″ X 6″ bit of 3/8″ plate. It will be positioned at a point on the bumper were the end of the swing arm end up when the arm is “closed”. Now imagine a truncated cone projecting horizontally back from that plate that fits into it’s female mate that is in the swing arm. The cone arrangement will, I think, locate and secure the arm to the back stop.

Instead of a draw latch I decided to have a captured screw handle on the swing arm. This screw handle will engage a threaded rod projecting out from the male cone.

Yeah, it doesn’t seem very clear and I don’t have a sketch of my idea. But here are the parts I have made so far.

From left to right: hand wheel/screw handle, male cone (will be attached to back stop), female cone partially inserted into bit of tubing that will be welded into the swing arm.

The cone couple. 10 degree included angle, made from Delrin. It is a tight fit into the aluminum tube that will house the female cone. A bit of glue and a couple of countersunk screws on the flange will hold the Delrin in the aluminum.

The hand wheel (going to call it that from now on) is made from scrap aluminum with a centre section of stainless steel pressed in. I mean really pressed in, a shrink fit. I heated the aluminum and drove the stainless into, the somewhat enlarged by heat, hole. Then I fancied it up with a turned recess and some holes. The stainless centre is threaded for 1/2″ NC.

The other side. The narrow section will be inside the “cage” that I have yet to make that will hold the hand wheel to the swing arm.

Arranged in order.

I had to make a collar to put on the narrow portion of the hand wheel to stop it falling out of the cage when unscrewed from the threaded rod. Of course I broke the damned tap when i was threading a set screw hole.

Grr.

I didn’t want to make another collar so i ground down the stuck tap (carbide burr on die grinder) and drilled for another set screw.

I was so pissed that i broke a tap I didn’t get the new hole exactly centred on the collar. Too bad, thats the way it is.

Enough of this for today.

Vanagon – rear bumper build news

Posted by albell in syncro, vanagon, vanagon mods on February 12, 2014

Man, with this damn bumper build, have I been dogging it or what? Here is a post showing just how little I have done over the last few months.

I have the actual bumper more or less in the shape I want it. So I went on to building the swing away tire carrier. I drilled a hole through the driver’s side corner and welded in a section of aluminum tubing.

On the top surface I ground things down flush. What I haven’t shown is the heavy duty bracing I did to the bumper in this area.

Skipping ahead (too lazy to rearrange how the pics were inserted), making Delrin bushings.

The shaft is a bit of 1″ stainless rod let into a bit of 1/2″ stainless plate, welded to rod on top surface.

End of rod drilled and tapped 1/2″ nc.

Bushing for top of tube.

Bottom bushing is similar to top bushing but has a smaller flange. Here is top bushing being inserted into tube. The fit on the stainless shaft was a nice sliding fit, but the fit into the tube was tight. This resulted in the shaft having a very tight fit into the installed bushings, too tight really, so I had to take shaft out and take off a couple of thousands (inch).

Oh here we have the bottom bushing being inserted.

Just to be clear, this shows how the bushings fit on the shaft.

Skipping ahead again… today I offered up the bumper to the van. Bear in mind the bumper is sitting on the stock bumper mounts. I will be making new mounts which will move the bumper closer to the van by about 1.5″. Please keep that in mind when you look at the pictures, it is important.

You can see the swing away arm installed. More on that arm further down. But right now see how the arm hits the bumper? I did machine things so that the mounting surface was parallel to the arm so either the bumper has a curve or the tube welded into the bumper was not 90 degrees to the bumper top surface. I think the latter is correct. I will mill the arm mounting surface to correct this.

I’m liking the shape of the bumper more and more. I wasn’t pleased at first, but I think it is ok. If i had to quibble I would say the end caps are too thick. That’s Lily, one of our two dogs, looking very bored with what is going on.

Ok, time to explain the arm. I had some water jet off-cuts, 1/4″ 6061 aluminum, that had curved ends. And the ends matched the radius of the stainless disk welded to the shaft in the bumper. I cut the off-cuts to fit inside the arm and ground down the ends to extend the radius around. I then stacked and inserted into the arm (2″ box, 1/4″ wall, 6061 aluminum) and welded them up. Then I drilled 3 holes for 12mm cap head bolts and threaded 3 holes on the stainless disk to match. I’ll try and remember to get some pics of the end for the next update.

Now to determine where the upright should be positioned on the arm. I used and old bike wheel (25″ diameter) to help me decide. Now remember the bumper is sitting further out than its final position. So if I welded things up as shown, the upright would hit the hatch.

Figuring out the lateral position. Have to avoid the tail light.

And have to make sure there is clearance when arm swung out to the side. Too close here.

So moved the upright inboard about an inch.

Better clearance when swung out.

But still too close to hatch.

That means relocating the upright to the rear face of the arm. Not as tidy hand will mean some re-thinking of my latch/arm securing set up.

All for now, I really have to make the bumper mounts and do final welding of the trailer hitch sub assembly (which is hidden inside the bumper). That sub assembly will provide more support to the bumper – I’ll be screwing the aluminum down hard to it.

Vanagon – measuring axle runout

Apologies for the dearth of postings over the last month or so. I have been doing a little Vanagon work but nothing that was ready to blog about (I’m looking at you, Mr Bumper Project). This post is an effort to get back on track.

I made up a spare axle (rear) with cv joints and boots some time ago and carried it around in the van thinking it would be a talisman against breaking an axle or cv joint during one of our logging road trips. Additionally, I had made some end caps for the cv joints so the joint could be all greased up and ready to go. Good friend Simon envied the idea so I gave him the assembly as a Xmas gift.

I ad another spare axle so the other day I dug it out and started to make up another spare assembly. I stripped it down, degreased the shaft, and took off the old paint and rust. I put the shaft on the lathe, tailstock and centre supporting the far end, to make painting easier. Yeah, I know, pretty sloppy habit to paint something on the lathe. But I covered the lathe to protect against overspray, put the lathe in back gear and had the shaft rotating as I sprayed the paint.

As I was doing that I noticed that the shaft had a bit of runout, i.e. it looked a little bent. Today the paint was hard enough to allow me to measure just how much runout the shaft has.

Shaft was supported at each end by V-blocks and the dial indicator positioned roughly between. I rotated the shaft by hand and watched the dial indicator. About a 0.013″ runout.

I did the same at both ends, one end it was around 0.003″ and the other end about 0.002″.

To be sure, this was a very quick and dirty way of measuring the runout, and to tell you the truth I have no idea if this is an acceptable amount of bent-ish-ness.