ATA – Martin Mars arrival at Patricia Bay

Posted by albell in around the airport on August 12, 2024

Later, during night, is to be hauled up slip and moved across the road to airport, and the B.C. Aviation Museum

Got some pics with camera and iPhone. Here are a couple of phone vids. Sorry about the framing etc, I was going back and forth from dig cam to iPhone and also trying to experience the moment.

I’ll edit and post more pics later .

Update 12/08/2024. Plane still moored in the bay. I guess I was wrong about haul out time

Update again, local rag says…

The aircraft is big — really big. It is 120 feet long with a 200-foot wingspan and has the ability to drop 25,000 litres of water in one pass. Moving it from the water to the museum will take several days.

First, the aircraft will have beaching gears (wheels) attached and be “de-watered” and winched up a ramp and onto a concrete apron.

Between Aug. 19 and 23, Nickel Brothers Moving will lift the Hawaii Mars onto a heavy-haul trailer, and when airport operations have ceased for the night, move the aircraft through the airport lands.

That will require fencing, light posts and power poles along the route to be moved out of the way.

Vanagon – simple pouches

Posted by albell in vanagon, vanagon mods on August 4, 2024

Recent samba thread about dash mounted , mag attached, pouches for phones, specs, whatever, got me thinking . I dont need that on dash but I do need a pouch to put my specs in when sleeping back in the cabin.

So, bad sewing me tried to make simple ones today. Started with a canvas one and of course got a hem on wrong side. But it works. Single 20mm magnet in the top hem .

Tried again with thin leather. No turning inside out this time . It worked. Setting aside my bad sewing .

I like them, will be useful back in cabin .

Update a day later… my sewing isn’t improving…

Update two… fridge quoits … stand outside van and chuck them in …

Vanagon – rear seat molle panel

Posted by albell in vanagon, vanagon mods on July 31, 2024

This is not something I needed. But was just an idea I thought I’d like to explore . My front seat back molle panel I made and showed a while back is great, and useful. But one on the rear seat… well maybe. I have played with shock cord loops and shoes, sandals, boots before I had it powder coated … and that does work so I think that’s what the main use will be .

Anyway…

It’s 0.088” thick aluminum , powder coated slight texture satin black. I made some spacers with locating bosses to put in spot where I thought it need some more support. Bit of sticky pad ( not double sided tape) on those spacers just to conform and support better.

Mounting screws to stock bolt locations, countersunk and with support spacer there too.

Update …. Shock cord crudely attached… full house of foot wear

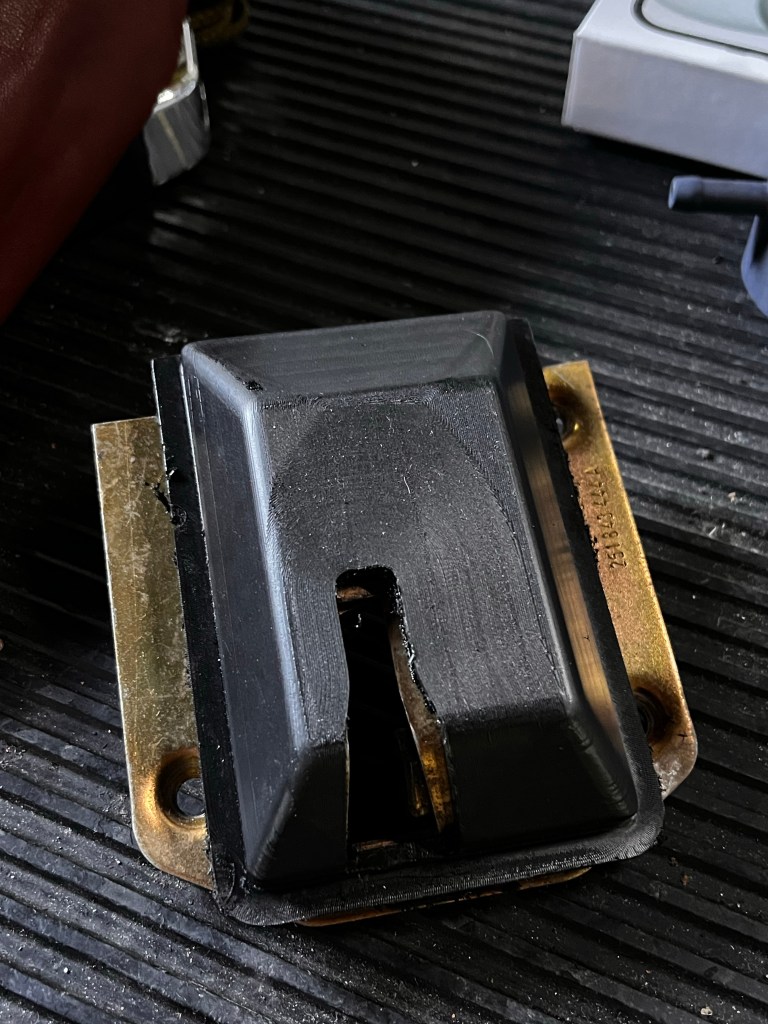

Vanagon – over the top slider door latch cover

Posted by albell in vanagon, vanagon mods on July 12, 2024

Update: Aug 2024

Finally powder coated and installed . Yeah not the best door card recovering, it’s a slightly waxed canvas.

My stock plastic one is degrading . My spare is degrading . Degradation all round.

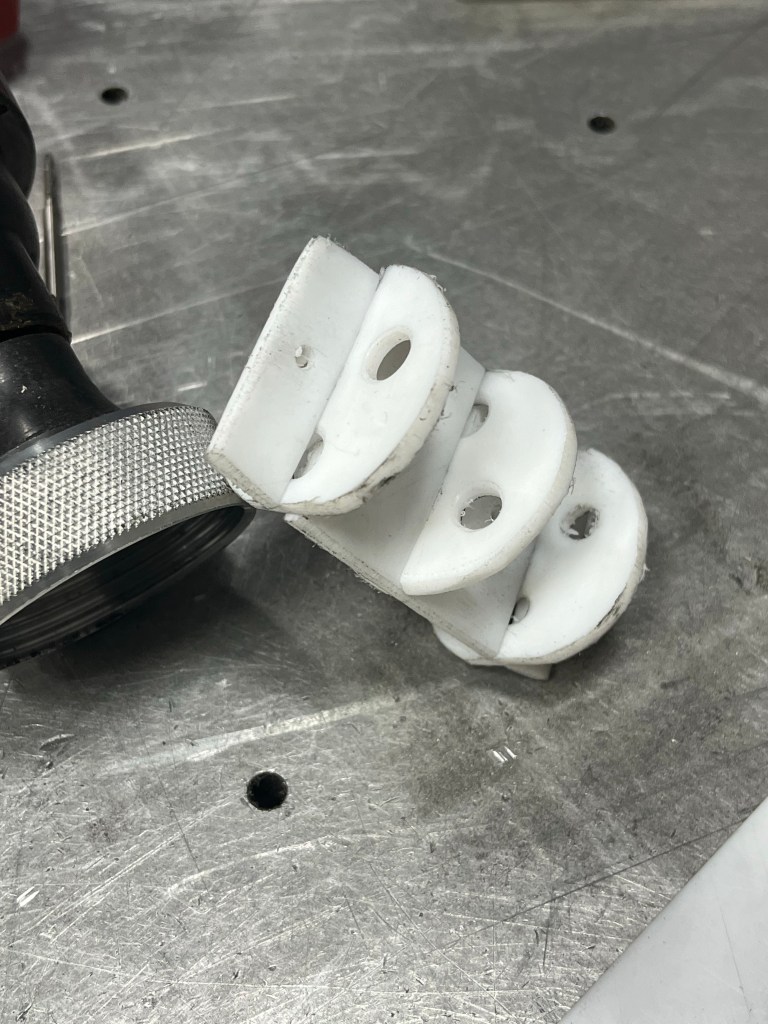

So I took one of my crappy stock plastic covers and really just measured up with calipers. Made a computer model and tried that out in hdpe. That plastic didn’t cut cleanly and I adjusted model cos the latch opening wasn’t right. Didn’t get that correction correct , but ok, good enough .

Went ahead with a block of aluminum , adjusted the shell thickness via stock to leave on the programming of cut . Turned out good enough .

Sandblasted it . I’ll powder coat black

Damn, forgot to add. If it fits I’ll post the step file of the model . you can 3d print it

Tools – sewing machine

Got this old singer 331k4 to do the canvas work I wanted to do on van. It’s a straight stitch industrial , clutch motor ,very fast.

I got it working ok, and learning to use it. Did I say it was fast? You that know, know that many convert the clutch motor to a more controllable dc servo motor. Or use jack shaft pulleys. Maybe one day, right now I have enough low speed control to do what I want.

Will punch through 1/8” leather even with fabric needle. Low speed control will be very very advisable if I’m going to do more leather. No second chance with leather.

Vanagon – kinda crazy recovering project

Posted by albell in vanagon, vanagon mods on July 2, 2024

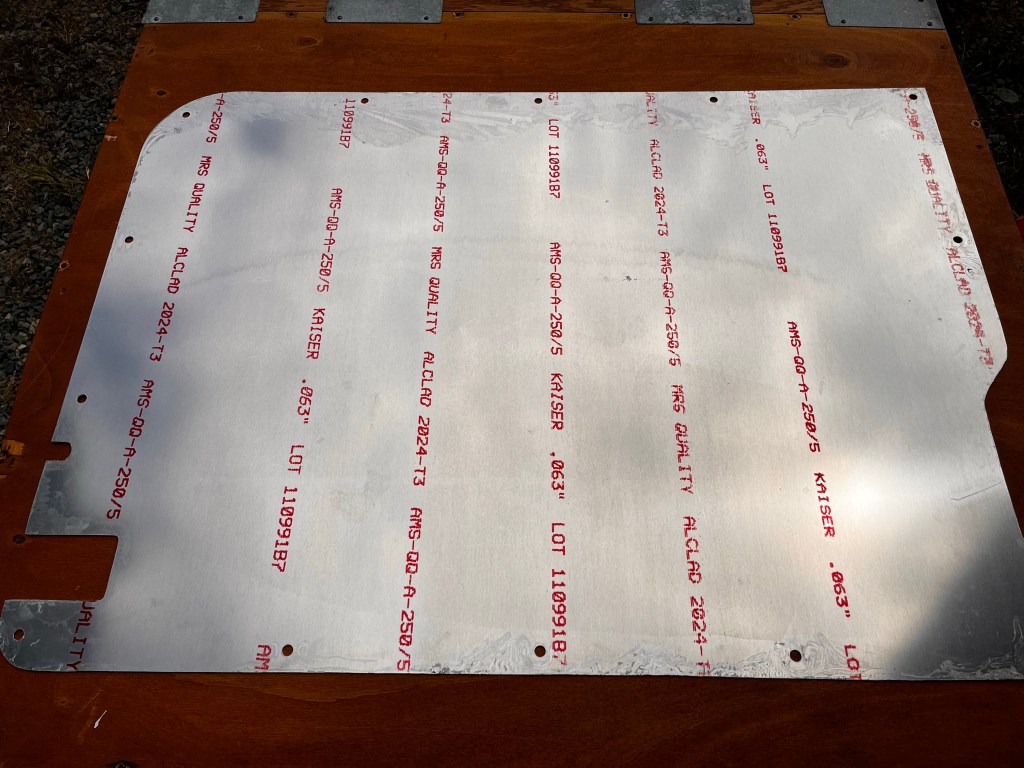

A few years ago I made an aluminum door card for the slider door. 1/16” 2024 , I traced the stock card and cut the aluminum by hand. No cnc 🙂

Been using it naked for all this time. But I had bought some olive drab water repellent canvas ( pic says 15 oz, but I recall now that weight was out of stock and I bought 12oz), and the crazy plan was to cover it with that.

Now I say crazy, as why would anyone do interior trimming in olive drab lightly waxed canvas?

Well I wanted that look, and I don’t mind the slight odour the fabric has. Yes, it has the waxed canvas smell.

Oh btw, I made my tintop syncro into a Westy 11-12 years ago using the parts from my ‘82 Westy.

I glued some 1/8” closed cell foam to the panel and then glued the fabric to the foam and wrapped it around the back. I had tested my contact cement a while back, how well would it glue the canvas to the aluminum. I was surprised that it really did glue it well.

The pleats you see in the corner in one of the pics were trimmed flat. Used some fasteners I found online to attached panel to door, they worked well and for the most part reusable (90% removed without damage from the naked panel )

Next day I refoamed and recovered the rear bench. Was way overdue. The stock foam was degrading. I had some 4” foam , but not quite enough to do it properly. Should have 1/2” or so of foam sticking out from the plywood base. I had enough foam to be exact match with plywood , I added quilting stuffing material to pad things out .

Oh and I don’t have an electric carving knife to cut the foam, but a hand held hacksaw blade worked very well

Corners sewn, fabric stapled to back of ply as in the stock 82.

Oh and I used 4” thick foam. I don’t know the density but it’s close to stock. The stuff I took off was about 3.5” thick. But it was old and compressed a bit. But… I think 4” foam might be a tad too thick. It’s tight between the seat back and the base. That’s not a problem sitting, or deployed as bed, but it’s impeding lifting the seat base fully to get to storage . I’m thinking of what to do.

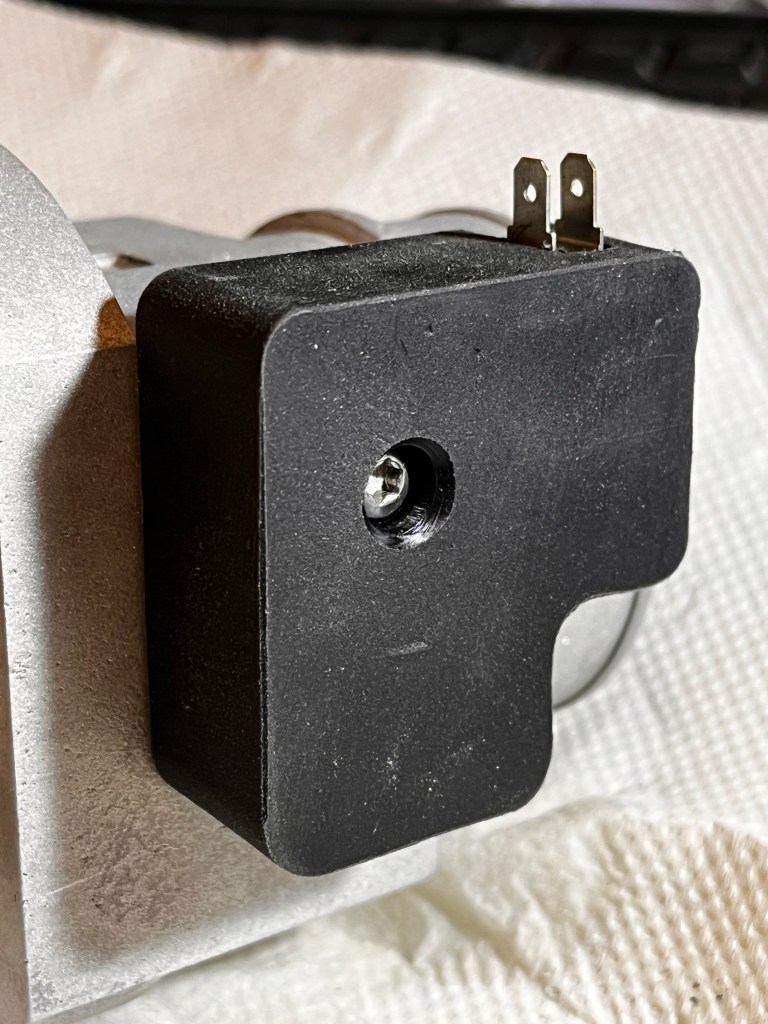

Vanagon – syncro fuel gauge sender ground

Posted by albell in syncro specific repairs, vanagon, vanagon mods on June 11, 2024

Did this mod a month or so ago, another one of Tom’s good tips. My fuel gauge had been reading low for quite a while , and then started acting even more erratic. Tom posted on samba a clever fix.

The short story is that the sender ground path is from the steel sender plate to a lug in the engine compartment, but the connection at the sender plate becomes corroded. Instead of trying to clean that corroded connection ( spade is steel not copper) , just add a ground wire from plate stud to somewhere close by on the body.

The only gotcha in this method is that the studs can be corroded and a stud may break when trying to loosen the nut. So plenty of penetrating oil and some good judgement in how much to force things is needed.

Pics are self explanatory , the samba link is the best reference.

This fix worked for me. Fuel gauge now much more accurate .

Vanagon – the THM ( Tom’s hatch mod)

Posted by albell in vanagon, vanagon mods on June 8, 2024

Update June 10, 2024: I’ve been told that in some countries it is illegal to have a rear license plate hatch that does not close by itself.

Old Tom, Sodo on the samba, decided he was sick of the springs on the license plate hatch at the rear. You know, coolant and oil checking hatch. Tired of propping it open. So he cut the springs.

His YouTube …

Being a Tom fanboy , I decided to do same. I didn’t have trouble removing screws as I lead a pure life , unlike Tom .

I bent the spring pigtail with the pliers, and it broke off. No need to grab angle grinder .

I gave the clip a bit of a push to the rear, left in pic. Didn’t seem to move, but it did clip better.

Antisieze on the screws back in, and a dab of grease on the clip.

Now I have a floppy hatch like the old Tom .

Vanagon – stock sink drain replacement

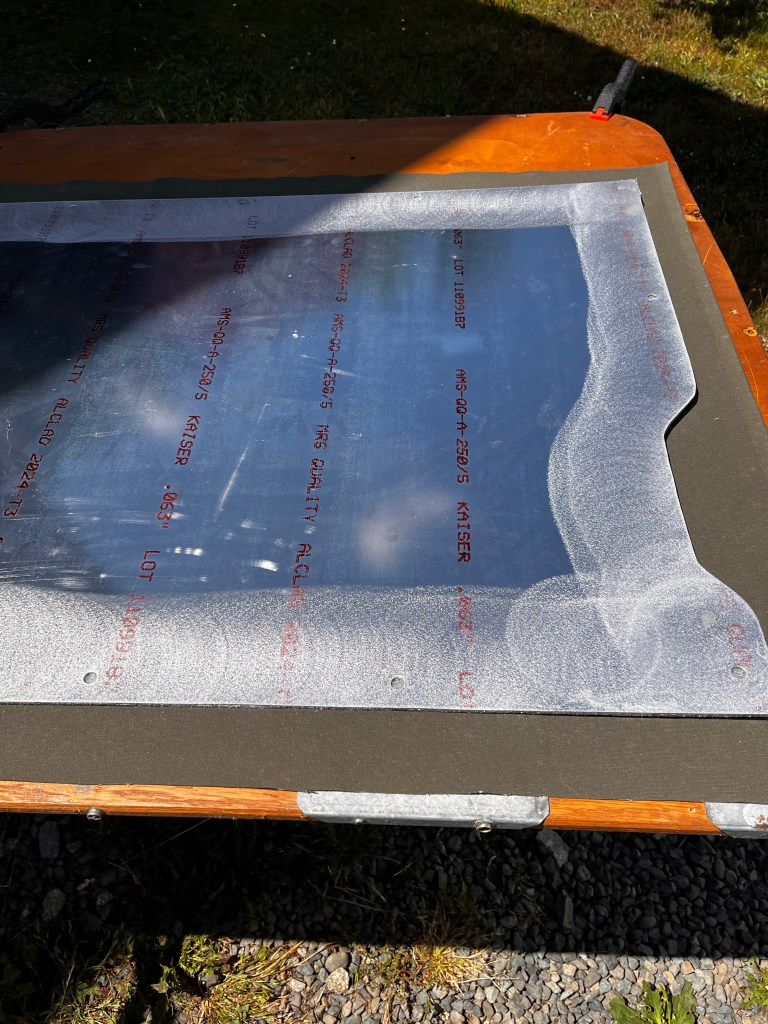

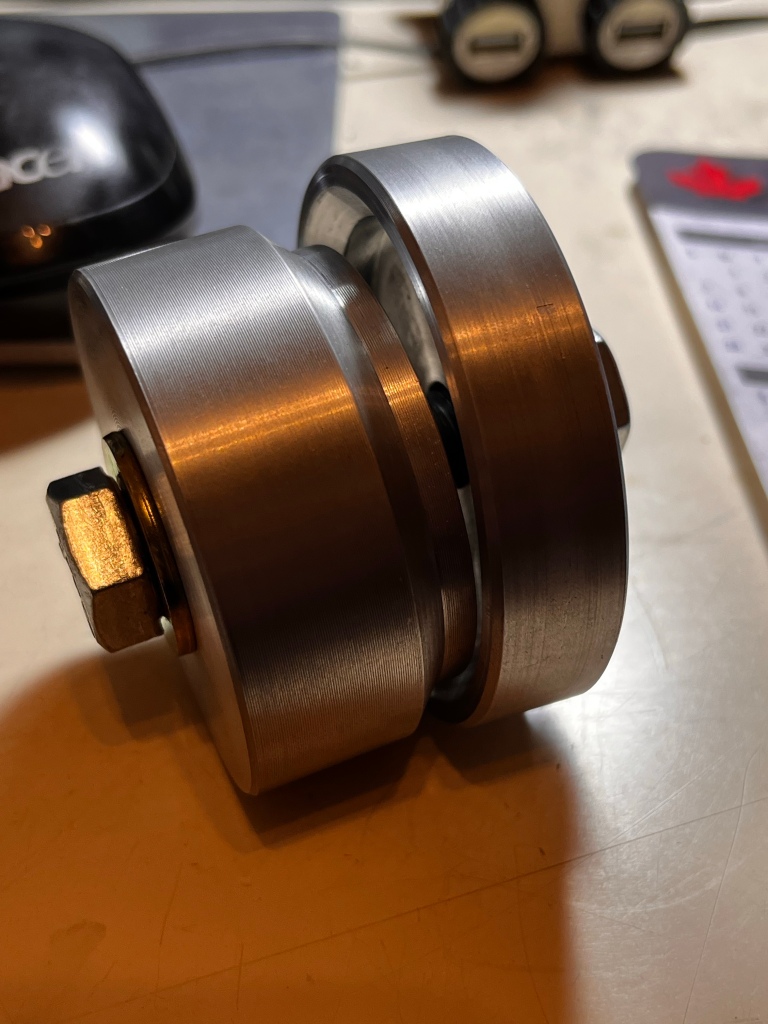

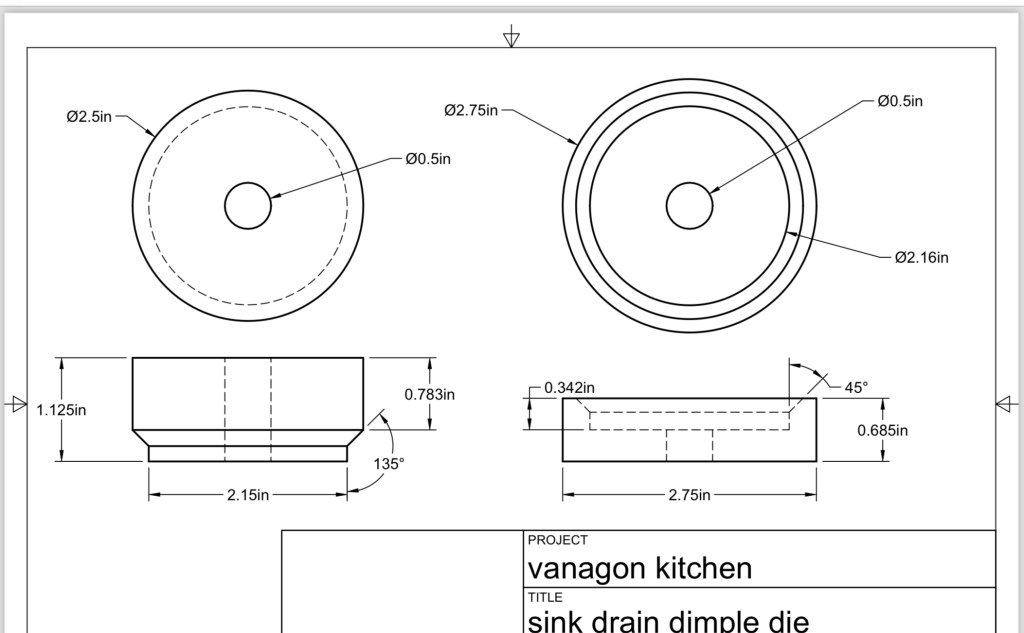

Posted by albell in vanagon, vanagon mods on June 3, 2024

Start of it, the low profile drain being used by the kids on samba

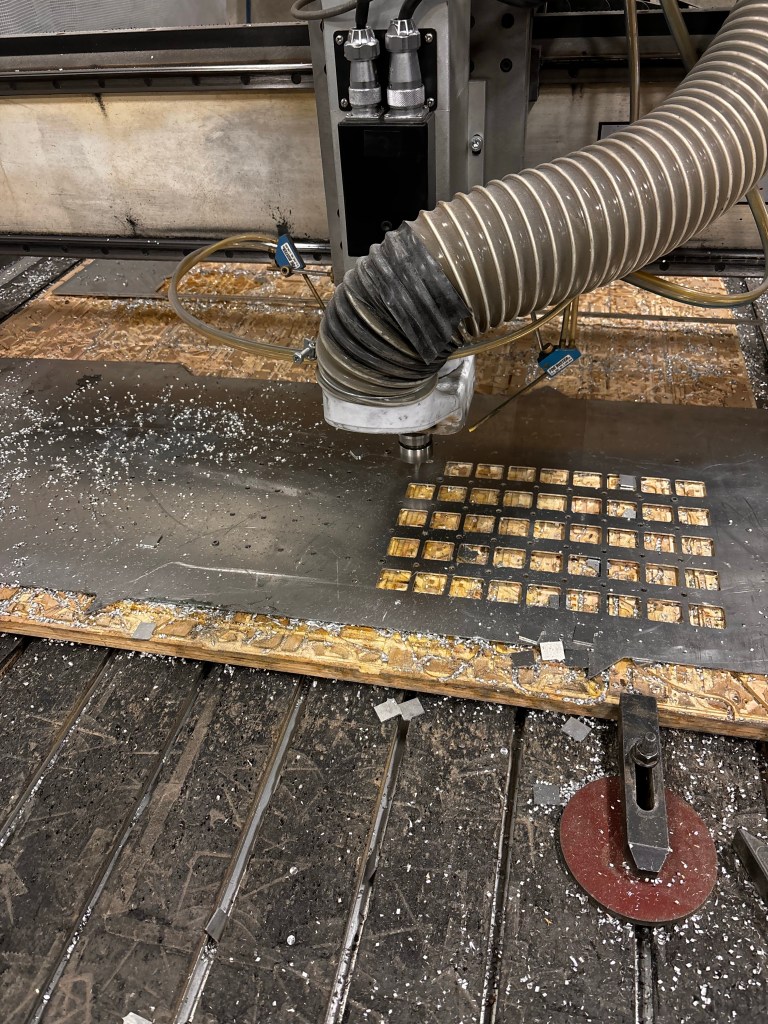

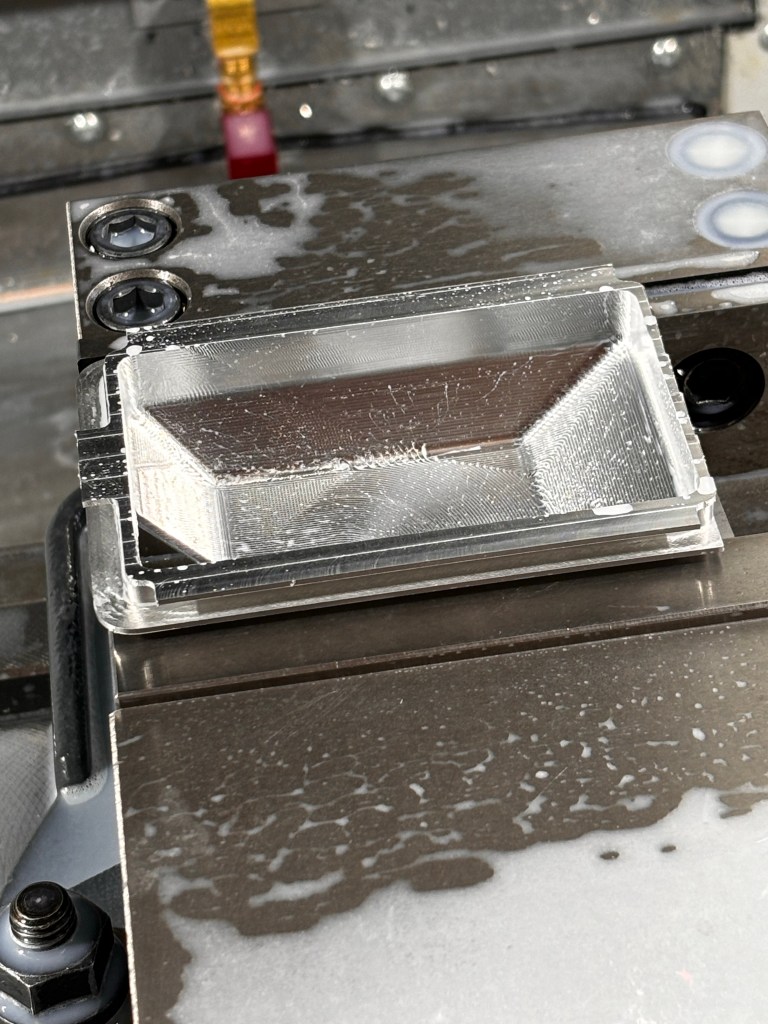

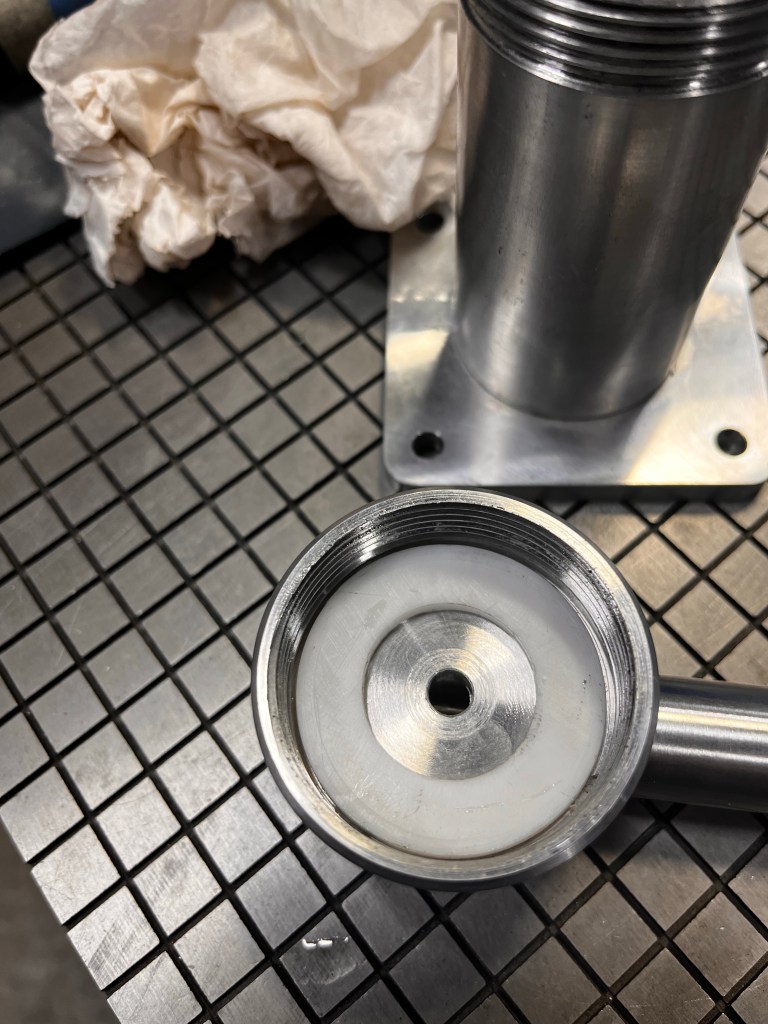

I didn’t like how the strainer fit into the sink hole. I didn’t like other methods of making it fit. So I made a dimple die thing.

Pics kinda explain it all. One note, if making the die , take another five thou ( inches) off the short straight section of the upper die. Shown as 2.150” in drawing . Make it 2.145”

Pics show the un mod situation and the adjusted .

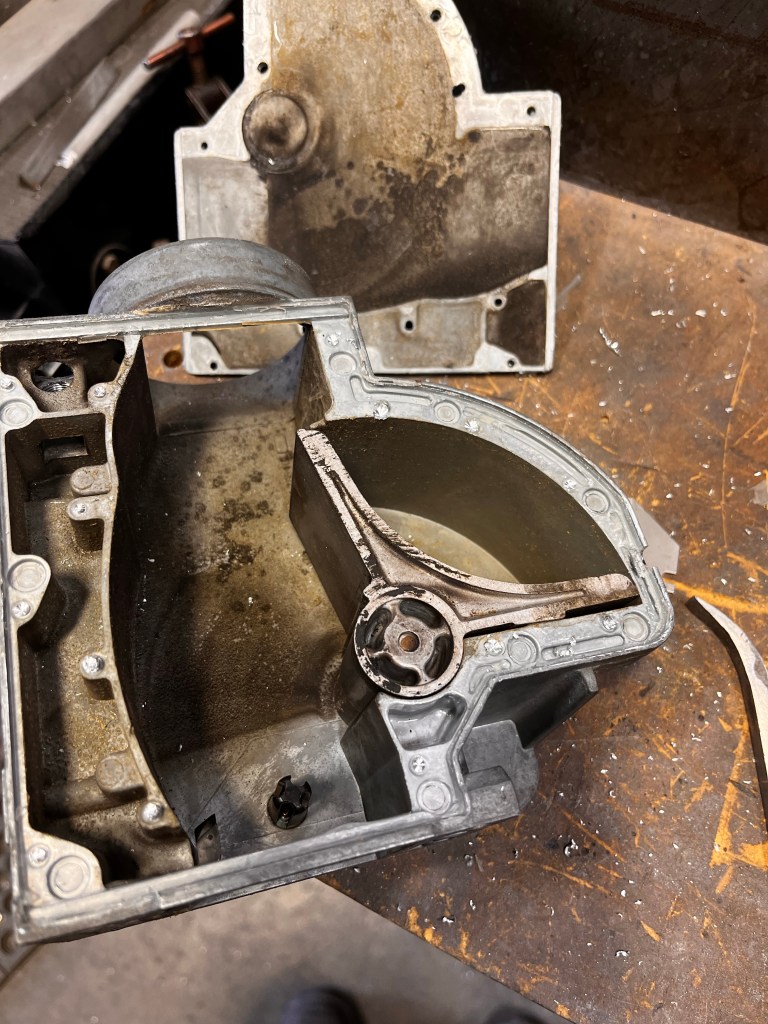

Vanagon – what does the AFM look like with back cover off?

Drilled out the rivets. Have a look . The bearing set up on the flap is a challenge … I mean trying to replace the bearings…

Vanagon – pre 85 slider door rear handle stud

Posted by albell in vanagon, vanagon mods on May 27, 2024

Was asked to make a pair for a friend. I had some 316 ss drops and machined the studs. Very much not the most efficient nor the most economical way to make them. I’ve posted a drawing and the step file. Sorry about the unprofessionally dimensioned drawing.

Oh, the step file … having issues uploading with the .stp extension so I’ve made it .txt

So change extension to .stp and it should be good

Vanagon – playing with old gowesty throttle body

Posted by albell in vanagon, vanagon mods on March 20, 2024

I grabbed the tb from a fire damaged van. So the anodizing on the body badly affected and all the meltables gone. That’s the tps and the bearing seals and additional shaft seals.

But the body was good. I blasted it, popped in new bearings, and thought I’d try to make an off the shelf, meaning my shelf, micro switch work as a tps sub.

Oh and I also had to make a cam for the switch , goes on the throttle shaft.

Oh yeah, of course, I made a delrin cover .

This was all just for the exercise. I haven’t tried it out .

Vanagon – AFM optical

Posted by albell in vanagon, vanagon mods on February 7, 2024

I’m testing this device. It’s the one on the right . The left hand AFM is what I’ve been using . Chinese made replacement board .

Only been a few days but has worked flawlessly . It replaces the carbon track board and the wiper with an optical sensor set up . More to come but I’ll say now it’s working perfectly. Smooth throttle response, prefect throttle tip in, no bucking on slow trailing throttle crawling .

Vanagon – another shift knob

Posted by albell in vanagon, vanagon mods on January 13, 2024

It got too cold for the aluminum shift knob I made a while back. I mean it, it’s not the greatest choice of material for a shift knob. So yesterday afternoon at end of work I quickly made one with a bit of wood. Scrap teak that I had at work for some reason. Could have been bigger in diameter but that’s what I had. Wood screwed onto a threaded boss in the aluminum base.

Pic of the cold all aluminum

The new semi wood

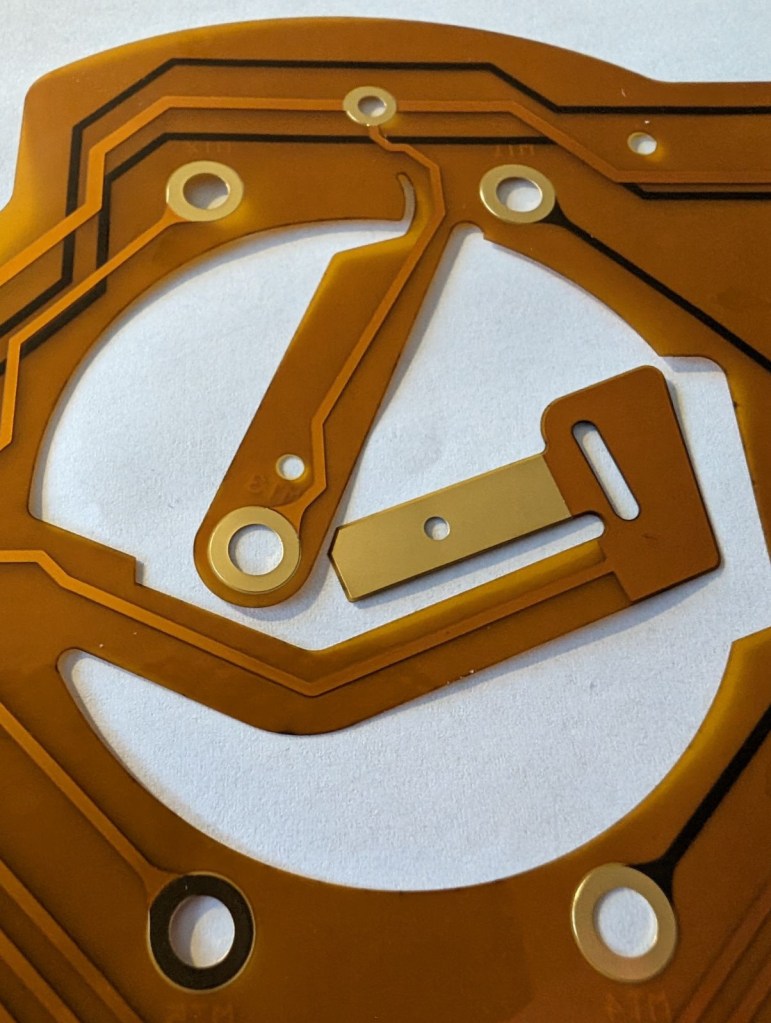

Vanagon – pre 85 instrument cluster foils

Good friend Greg who is making the post 85 model year dash foils has made some prototype pre 85 foils. They look good, gonna be testing them immediatley.

You can contact him here

greg@pathfinderdesigns.com

Vanagon – Molle panel thing with more stuff

Posted by albell in vanagon, vanagon mods on December 27, 2023

That thing I posted a while back, more stuff on it. Bag has the pump and shower head ( https://www.flextail.com/en-ca/products/max-shower).

Shower was Xmas gift from good friends Simon and Maria. Works very well testing it at home .

Tools – super rare Hazet

The tool caddy and can caddy, both very rare 🙂

Sitting in not so rare 172hd

Hope you all having time off and fun

Vanagon – front door, inside release surround

Posted by albell in vanagon, vanagon mods on December 24, 2023

I went down this silly rabbit hole about a month ago. I thought it would be easy to make a pair of door latch surrounds. Well it wasn’t , made mistake after mistake. Finally got something that works, but it sure wasn’t worth the effort.

Yes, there are aftermarket aluminum versions. I think it’s uniwerks that sells some UK made units. That set includes the trigger and the trigger mount. I chose to try and use the stock trigger and mount, and that was a huge part of my problem.

Pics show some of my attempts, including 3d prints. And my final attempt, the “good enough, I’m not gonna waste any more time” , powder coated and on the door.

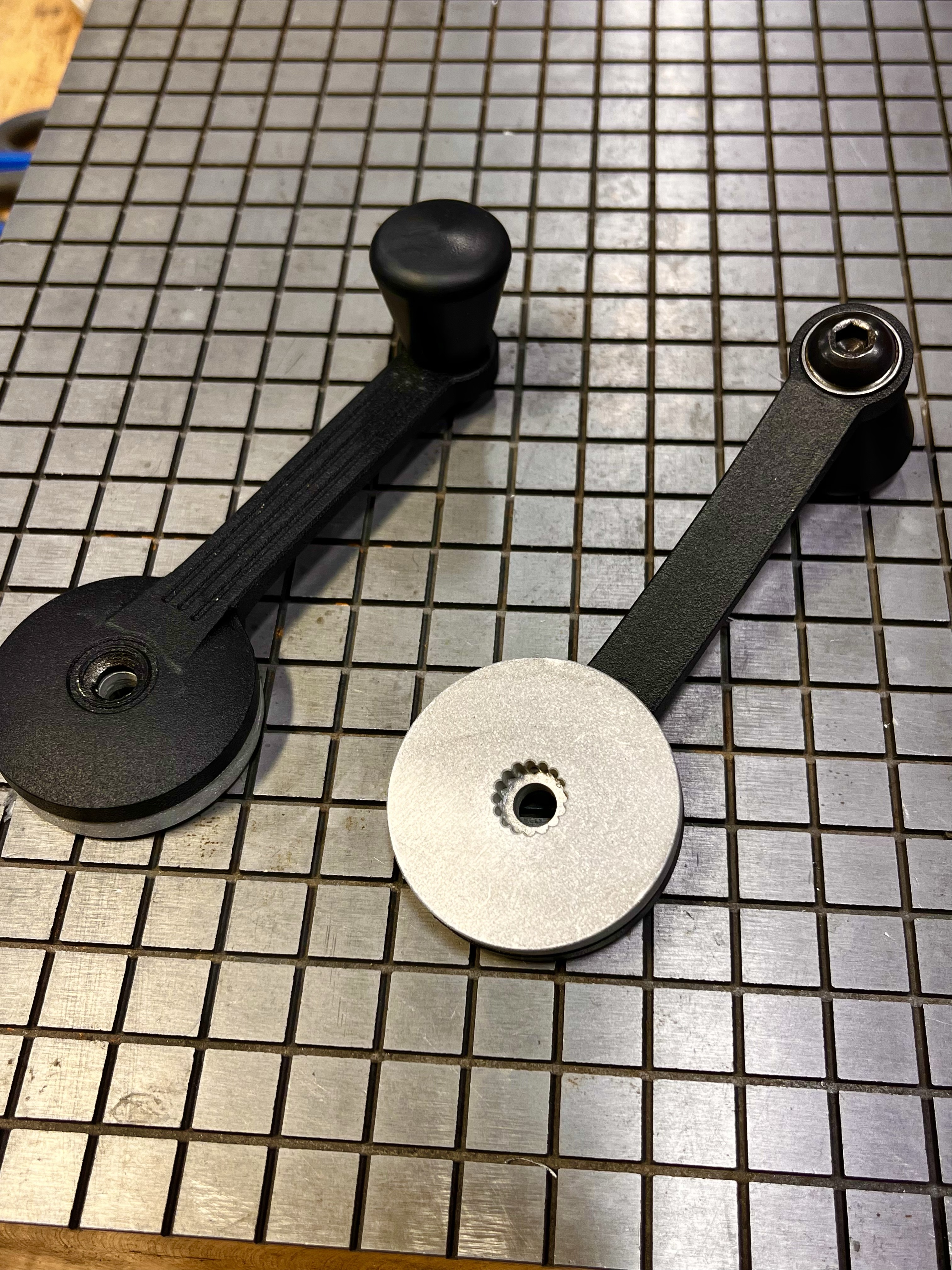

Vanagon – old project – window winders

Posted by albell in vanagon, vanagon mods on December 23, 2023

Started fooling with this about 4 years ago then I lost interest. Was more of a design exercise than anything else. I had this notion of a spacer set up, keyed to the handle…. Blah blah…

I don’t have a broach to cut the internal splines so I did a kludge by drilling small holes then boring a boring with a slight taper. Seems to work, but I haven’t used handles much.

The knobs are delrin, and a bearing pressed and glued into handle. That part of the experiment works well.

I think I’ll revisit this project soon and do a bent handle for more clearance. I’ll keep the delrin knob as I like that better than the knurled knob on the GW handles ( been using them for a year, I find the knurled knob kinda not great).

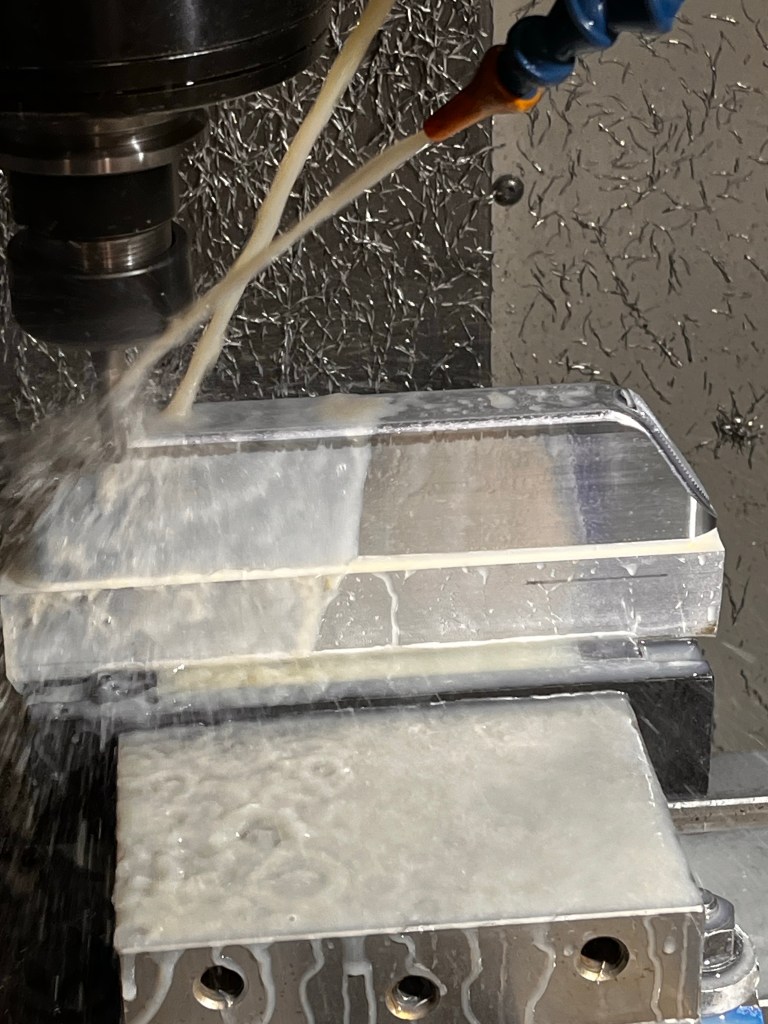

Vanagon – aluminum door handles

Posted by albell in vanagon, vanagon mods on December 9, 2023

Another thing I’ve been playing with. And I’ve posted about them but they deserve their own post .

Machined aluminum handles for front door. Yeah, there are some for sale on the market still, I think. Syncrotimes https://www.syncrotimes.com/

They do an anodized version for a crazy low price. Check them out.

Anyway, back to me .

I’m not a fan of “billet” aluminum things. Maybe it’s because I’m matching aluminum all day and I really don’t want to see it all the time 🙂

Plus they are cold, or hot depending on the weather, to the touch.

But I made these. Solid and ones with holes. And once they are powder coated, by golly I like them. Don’t seem as cold once painted.

It’s a two set up operation for machining as you can see in the pics.. Then I tumbled them, and painted some. I left a pair of the solid versions unpainted , polished the tumbled finish and wondering if I should try a partial leather wrap .

Notice I’m only using the two large screws that go into the plastic insert in the door. The smaller screws are not needed.

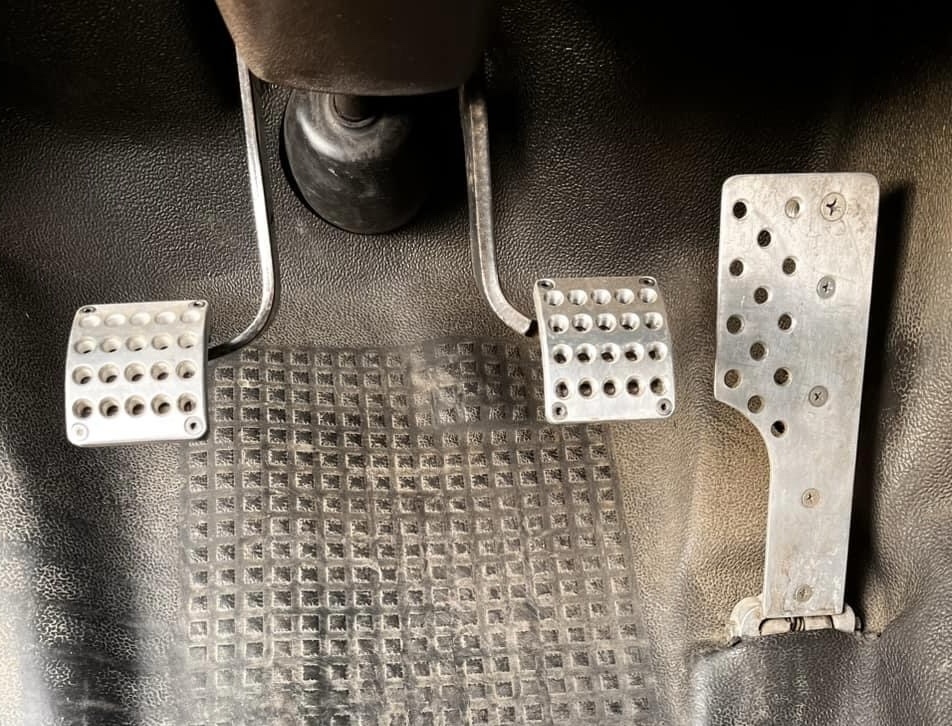

Vanagon – brake pedal pads

Posted by albell in vanagon, vanagon mods on December 9, 2023

I posted about them a few weeks ago but decided to post again by themselves .

Something I’ve been working on , on and off since summer. I’ve tried out various styles but I like the rectangular recessed ones best.

They are 1/4” 5052 aluminum, machined, bent, then powder coated. Held onto the stock pedal ( after the plastic stock pads are removed) by cross bars top and bottom, m4 socket headed cap screws. The bars go behind the pedal.

I’ve had a pair of non painted, raw aluminum ones on van since summer. There’s no problem with a wet foot slipping off pedal .

Pics show a sample of the designs I tried, the ones in the van, and the powder coated ones I’m going with.

Yes I’m going to make a few to sell.

Vanagon – behind seat storage rack

Posted by albell in vanagon, vanagon mods on November 30, 2023

Ok, right away, I know this will appeal to only a few. But it works well, it’s stiff and secure. I quickly machined a bear spray holder and printed a flashlight holder for examples of things to attach. Bag type things can use Velcro straps. Yes, it’s the molle/PALS type system.

I’ll make them to sell if I get enough interest

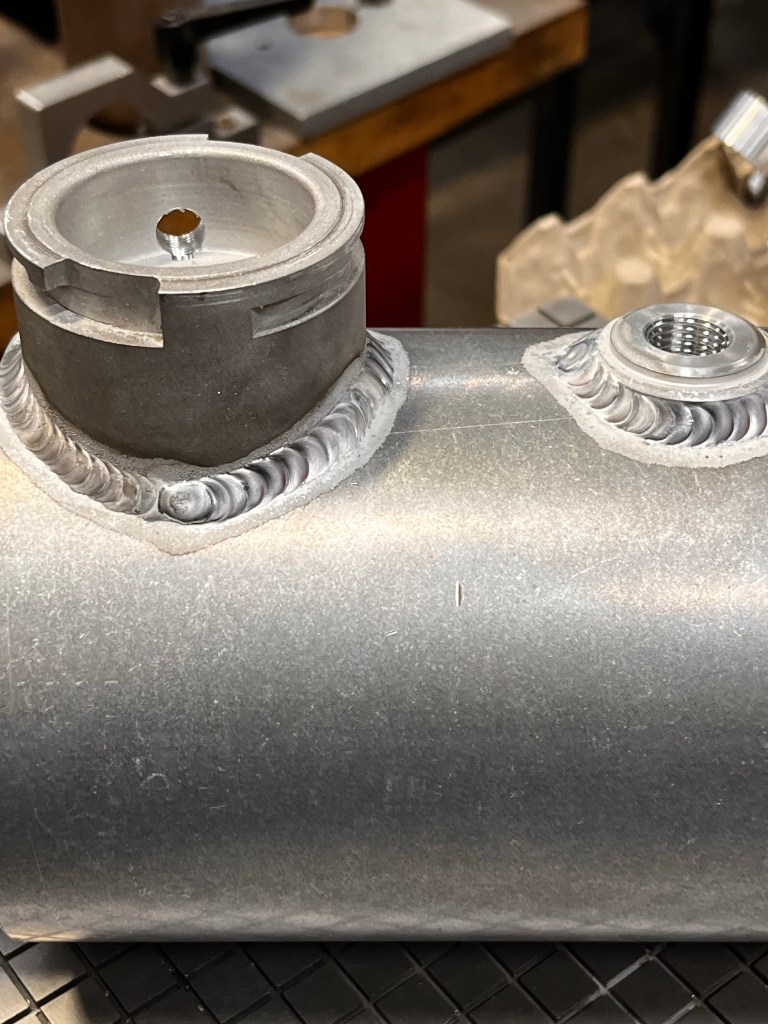

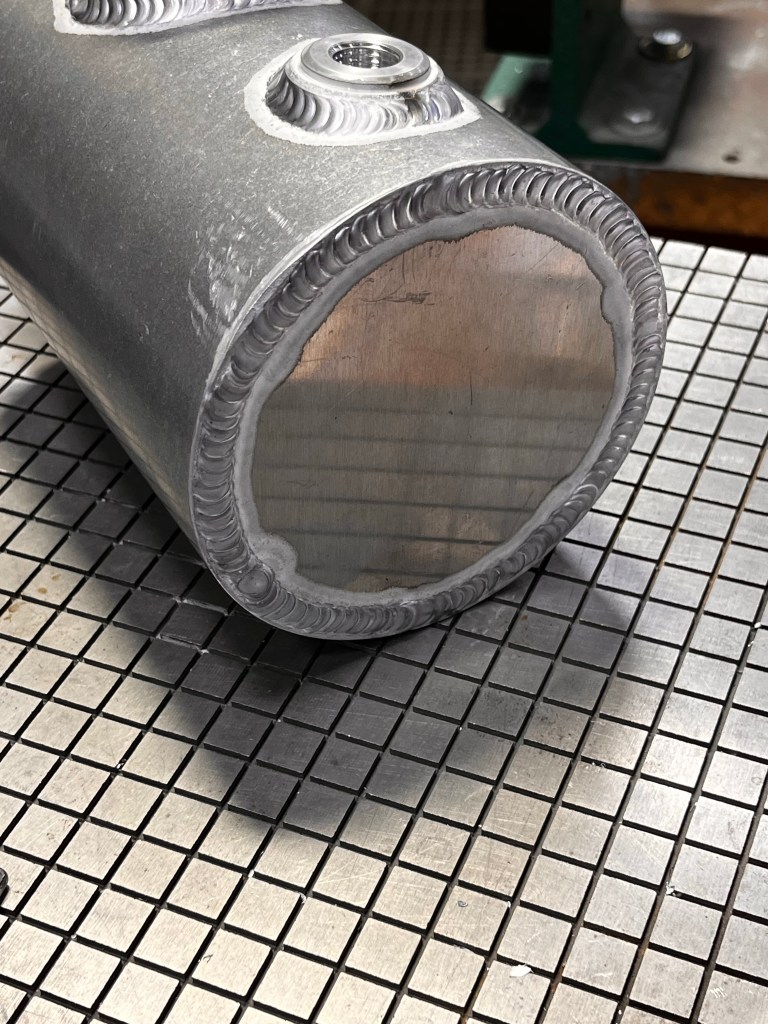

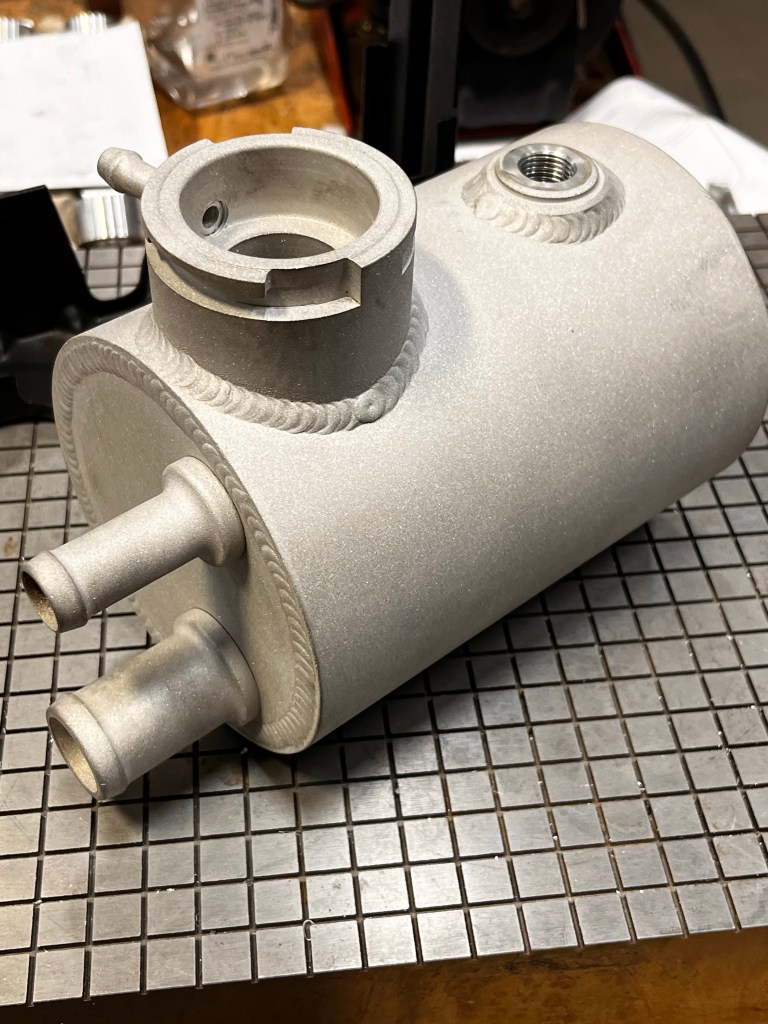

Vanagon – catch up

Been missing, I know .

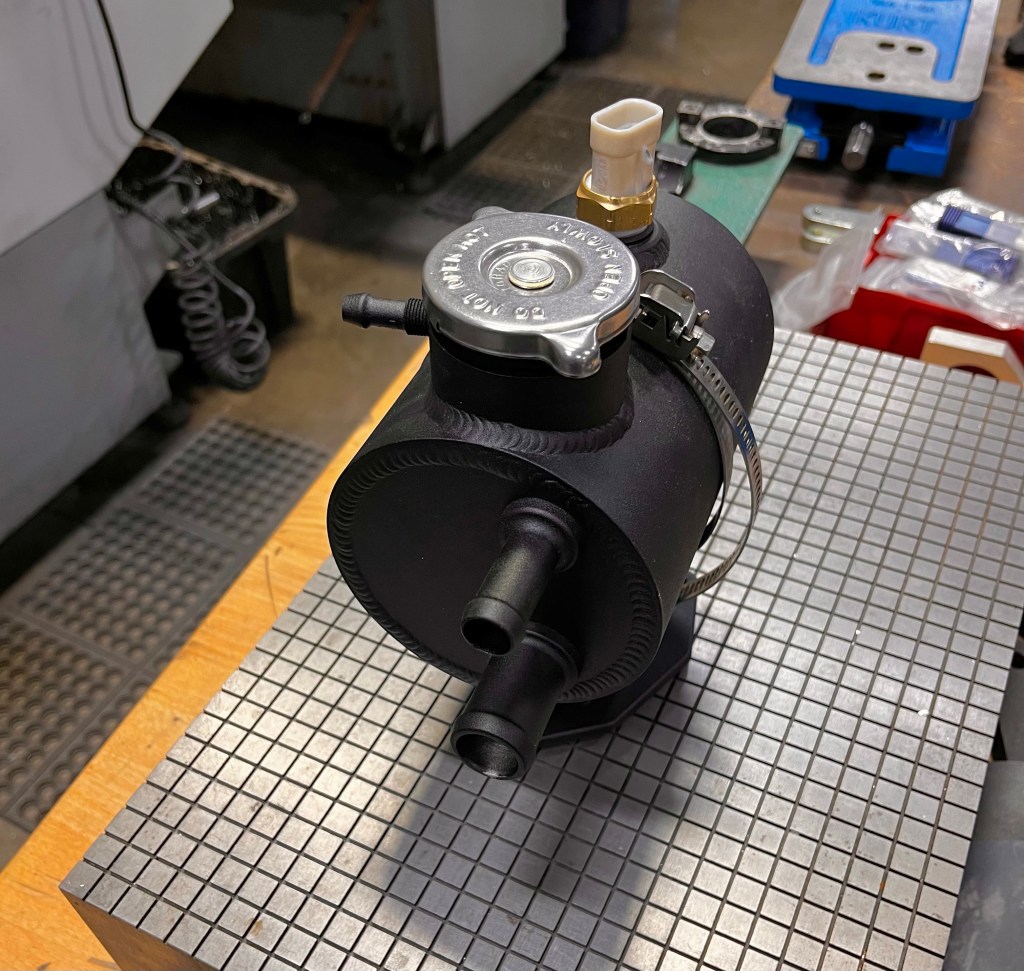

First up is crazy heavy duty expansion tank, I don’t like that name it’s more a header tank.

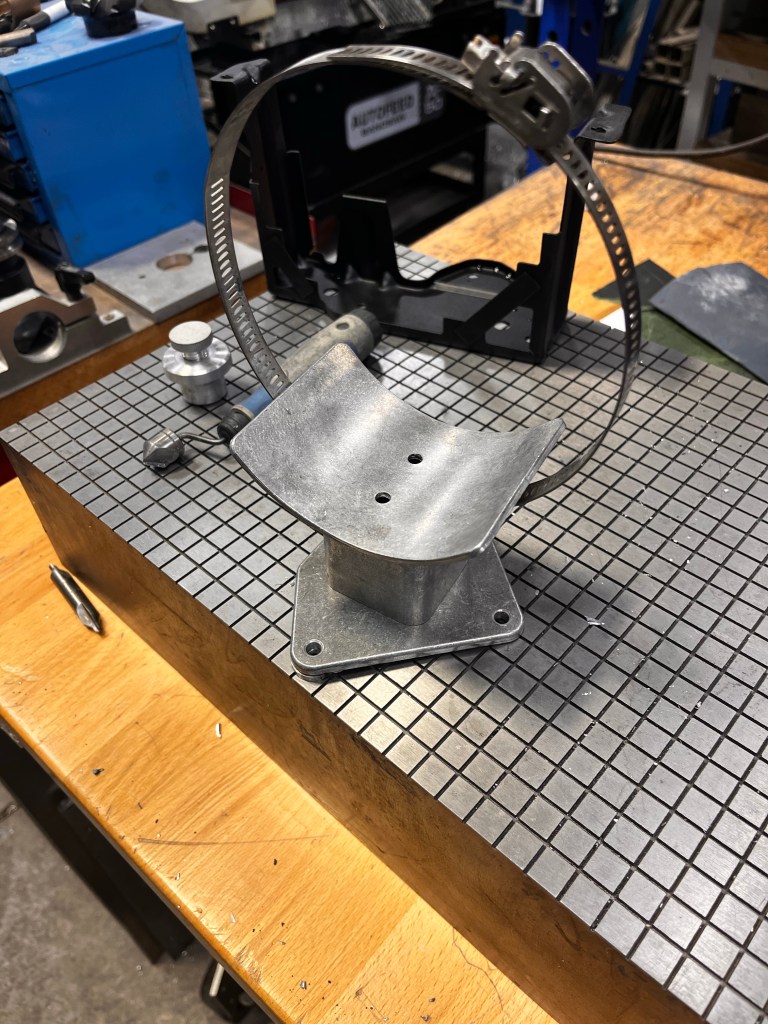

But here it is, different level sensor. It’s a bona fide proper one not the cheap import you might have seen elsewhere. yeah I did machine that cap spigot.

Not installed yet. Want to make rubber pads for under the clamp and on the pedestal base .

Nest up are more pedal pads. I think I’m close to a good version. There’s a pic here of a few of my prototypes. The powder coated black ones are what I’m going with

And billet, again I hate that term, aluminum door handles. I’m happy with this design that has holes in it. Feels good, looks good. Got pic of a solid version, unpainted but polished. Maybe that’s ok too, maybe better if partially leather wrapped .

Vanagon – oil tower vent thing

Posted by albell in vanagon, vanagon mods on September 2, 2023

Revised my thinking on an oil tower. I posted about original plan a few weeks ago. But now I’m not putting putting on a golf mkii “pcv” thing on top of my aluminum tower (Teflon baffles inside ) i took one apart and in all respects except for the diaphragm size, it’s identical to the van set up.

I’m doing this one free flow thru. I’ll see how it goes.

Hose barb Part just a tight press fit. Cap screws on , Teflon washer to seal.

If you want to read thru my understanding of the stock tower… here you go

The main body of the tower has a removable baffle . Above that you can see a right angled bent tube. This tube has a small hole in it facing down, towards the engine. This tube continues out thru the tower and is what connects to the engine air intake upstream of the throttle body via rubber hose. Also in that path is a heating element , with a narrow orifice, maybe 5mm diameter. Heating element to prevent icing , the narrow orifice presumably to restrict air flow to a degree.

Back at the tower, inside, where the tube curves 90 degrees up ( and again, mention of the small hole on the underside of that bend) the tube ends and there is a rather weak spring supporting a rubber diaphragm. The spring keeps the diaphragm off the end of that tube. In other words, the passage from the crankcase to the intake boot is clear. The diaphragm is attached to the tower top, with some space above it. There is a small hole on the underside of the top of the tower that connects to the space above the diaphragm, thus keeping that space at atmospheric pressure.

So when does that diaphragm do anything? Well… as far as I can tell the diaphragm is pulled down to block the bent tube leading out of the tower when you have greater than a certain amount of intake vacuum. Probably not at idle or at wide open throttle . More likely at some mid throttle range.

Btw, the pro training manual has description of the tower and function but I’m not sure about the statements made there of when there is high or low intake manifold vacuum.

That little hole at the bend of the tube inside.. I’m guess that allows some passage from crankcase even when diaphragm pulled down under high intake vacuum.

In short, my understanding is… the crankcase vapours are allowed to travel up thru the tower and then into the intake manifold when there is not sufficient intake manifold vacuum to overcome the spring pressure and pull the diaphragm down. When there is sufficient vacuum then the diaphragm is pulled down and the passage is closed saved for the little bleed hole .

Update December 2023. Been running it since I posted this. Seems to work fine, can’t detect any engine running differences. I had a look inside it after a couple of weeks, nothing much to report. Oh one thing, you see how I used a Teflon gasket instead of an oring. Was slightly worried that joint would weep oil. But it hasn’t. I’ll add those pics to the gallery. I’ll prob look inside again over the Xmas break.

Trip – Klanawa again

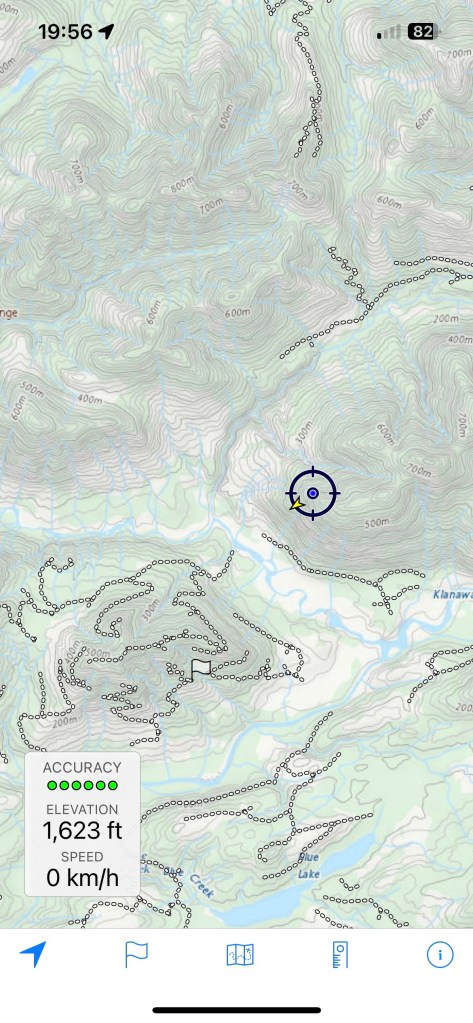

Couple weeks ago we took a week long trip to the Klanawa. First night was on the nitinat though, just upstream of the bridge. Then into the Klanawa valley, exploring a bit, finally settling at Tscowis creek. A campsite that we’ve used before. For some reason it doesn’t sit well with me. Dunno why. Nice creek which is always cold, the nearby logging road not busy. I dunno, I just prefer other spots. Anyway, two nights there then off exploring and with the idea of camping up ona hill over looking the Tscowis. I’ve marked a pic with arrow locating the high spot seen from Tscowis. Also I’ve included a map grab.

Lovely being high. Could see the pacific when the fog wasn’t in.

Saw couple of bear, some young elk, and Vauxs Swift ( at the high spot)

End of week the smoke from fires in the interior of BC came in, high up. Next day though the smoke was low, hazy and aromatic.

Vanagon – pcv Tower Experiment

Posted by albell in vanagon, vanagon mods on August 11, 2023

Just fooling with an idea. The 90’s era Vw pcv valve shown here is a place holder of sorts.

Tower packed with Teflon. Screw top in case needs cleaning without taking tower off engine block. I’ll try it out in a bit, going on holiday next week , exploring Klanawa again

Vanagon – jagdwagen syncro doka winch mount model

Had the mount scanned. Can play with model now, adjust it to fit modern winch bolt pattern.

Vanagon – rear heater hoses and tees

This is kinda not very informative. I didn’t get pics under the van showing the tee installation. I was grimy from the dirt falling from van, and working on gravel/dirt driveway, van not jacked up.

Last weekend noticed one of my rear heater tees was leaking . I fiddled around with it , trimming ends if hose, tightening clamps etc. finally it blew up under pressure testing. I had a spare plastic one and put it in. During the pressure testing I noticed one of the hoses to rear heater was weeping. So at that time I spliced in a section of hose to get by.

This weekend I had new hose and some parts I made. I showed the tees in previous post The hose from the tee under van to the rear heater is nominal 1/2”, but at the heater it swells to 5/8”.

Because of its routing I wasn’t confident I could run 5/8 from tee to heater. Plus there are grommets to pass thru . So I went 1/2” and used the stock hose ends at the heater. Yeah, means another connection.

All went ok, I’ll spare you the details except that I think routing the hoses is harder on Syncro. Plus one of them has a ninety at tee end. I managed to lead the hose well enough to not kink there.

Just a note, yeah the paper on the inside of rear bench is crap. It’s an 82 diesel westy interior inmy 86 syncro… I put in rear heater in my 82 and decided to mount it to one side to maximize storage under bench, so when I used that interior to westyfy my Syncro ….. that’s where the heater went.

Anyway…. No leaks so far

Vanagon – engine stand

Decided to make an engine stand a few months ago. Took me a while to finish. The computer model was not quite what I got in the end, I changed as I went.

It’s pretty solid. Since the pics taken it’s bolted to bench. Still not painted though , and still using nits as spacer on that bolt .