Posts Tagged vanagon

Vanagon – sliding window felt and interior light switch

Posted by albell in vanagon, vanagon mods on June 21, 2013

A couple of small things. First off is replacing the window felt in the sliding windows. You can only get at the horizontal felt with the window in the van. But if the entire window is out, then the frame can be spread and the sliding portion removed and you can get at the vertical felt seal. I found some felt seal at a local RV supply store, and I think that auto glass outfits can supply it too. I looked in the hardware store at some patio door felt seal but it wasn’t quite the right size. You might have better luck.

So open your window and at the forward end pull out the rubber seal a little, just so that you can get better access to the seal. Grab the seal and slip it out, little by little as it has to make a sharp turn out to get past the window frame. My old seal was very worn and brittle, kept breaking as I pulled it out. The new seal goes in the way the old seal came out. It is easier than it looks.

The new seal is so much fluffier than the old one and the window initially did not slide very easily. But after a day the felt compresses a bit and sliding is easier.

Picture time. Three felt seals: on the left is the new seal (yeah, not the same colour), middle is a bit of what looks like unused original seal (lord knows where I got it), and on the right is the old seal.

Back side. And yes, the new dark seal has an peel off backing, adhesive under. I din’t have any problem installing it with backing on.

An attempt at a side shot. The old seal is very worn out.

Installed. The dark colour is not that bad.

Next up is a silly little mod. My van was originally a 7 passenger tin top and so it has interior/cabin light switches on all doors, including the hatch. Factory Westies do not have door switches on the sliding door and the rear hatch. So what you say? Well, when you are camping, and you have the sliding door open then the interior/cabin lights are on whether you want them on or not. Kinda silly during the day, and not really needed at night if you have added lighting on a different circuit. Of course you can turn off each individual light, or you can find some of those door switches that have the little notch in the plunger so you can have the plunger stay depressed, but jings, where’s the fun in that?

So one evening I made a little switch plate to fit where my old Webasto BBW46 control panel was (I gave up on the heater, removed all the plumbing during the head replacement job). I didn’t use the sexiest of switches, but they are what I had. I used two just because one switch looked silly. And the two switches left an awkward space between them, so I added some LEDs.

So what I did with the wiring was to intercept the power wire to the interior lights (on my van it comes out out panel from B12 connection, then splits at connector T2c. That power feed also supplies radio and make-up mirror light. I did not have to worry about power to radio, I’m supplying it another way. Ok, I cut that power feed and connected it across on of the new switches. Just for fun I wired in the amber LED to light up when switch is closed. So to turn off all the door switched lights I just have to flip one switch.

The green LED is connected to my Blue Seas ACR and lights up when the main and auxiliary batteries are combined. The red LED is still waiting for a use, as is the other switch.

Vanagon – Q and D head replacement – catch up and conclusion?

So the deed is done, but the doer not quite undone. It turned out to be more of a chore than I bargained for. Let me see if I can relate what happened from the time took the engine off the stand to how things are today.

The engine had to be removed from the stand to get the clutch and flywheel on. I decided to replace the main oil seal there. This pic shows two used seals on top row, lower left is a seal I bought before I bought the Victor Reinz gasket kit, and the lower right is the seal that came with the kit.

Side view, from left to right, the 2 used seals, the kit seal, and the bought on its own seal.

I decided to use the larger seal. Before installing I de-burred the case.

Not quite all the way in, should be recessed a little more. One of the old seals was used between hammer and new seal. Pilot bearing got some moly grease.

I didn’t forget to install new felt ring and new O-ring in flywheel (I used the clutch install tool to form and settle the felt seal in place a little nicer than what you see in the pic.

i installed the flywheel and tightened the bolts. There is no nice way to say this, I fucked up. What happened was the thrust bearing (which sits behind the thin shims behind the seal) had fallen out of its recess and jammed as I tightened up the flywheel bolts. It smooshed over the the edge of its recess. When I figured out what had happened I was scunnered. I used a series of bearing scrapers to carefully cut away the smooshed part of the case, trying to not damage the flat section where the thrust washer sits. I checked the crankshaft endplay a few times and used a combo of shims to get at an endplay of 0.005″. Was the best I could do. So it was the thinner of the 2 new oil seals I finally ended up using (the thicker one destroyed during removal to fix thrust bearing).

Okay, after a little self flagellation I got back at it. The connection between the throttle body and the intake plenum needs a special gasket. A truncated cone affair and my old one was really torn up. Seems to be NLA, but I think a replacement is on the way to me (right Bill?) and in the meantime I wrapped some silicone repair tape around the plenum “spigot”. Turned out to be, well at least it appears to be, a fairly good fix.

Getting the engine mated to the transmission took me an entire morning. I had the transmission on a bottle jack so I could move it up and down, and the engine was on a hoist. Still it was difficult for me to get things connected. I finally got it on, and the joint sealed with silicone (one of those syncro things).

All the electrical, fuel, and coolant connections made. Engine filled with oil and coolant. Coil power feed removed and engine turned over. No oil pressure. None. Cranking and cranking, even a 10 second run with coil connected. No pressure. This job was killing me. Of course it turned out to be a rookie mistake by me. I should have packed a little grease in the oil pump to help it pull some prime. I got the pump primed by removing the oil filter and cranking until oil came out. Filter back on and then cranking.. pressure!

But not much pressure really. Cold idle was 25 psi, cold max pressure was 60 psi. When hot, oil pressure was close to zero, max was 25 psi. With oil temp >80C, and at 2000 rpm, oil pressure was 25 psi. What the heck could be going on? I’m going to make a long story short. I removed skid plate and then got at the pressure relief valve. Took it out and measured the spring. From the Samba I found out that a new spring is 62 point something mm long. My spring was 59 mm long. So I made a spacer.

Back in it goes, start up engine… I got 30 psi cold at idle, max 75 psi. Hot pressures were 7-10 psi idle, 45 psi max, and just shy of 20 psi at 2000 rpm.

During all this the oil drain plug hole stripped. Damn and blast, what else can go wrong? I took a 14 mm bolt, one that was longer than the drain plug, drilled and rapped for a 13 mmm head bolt, turned down the head of the 14mm bolts, made a Delrin washer and ended up with a new plug that was longer and caught some of the remaining un stripped threads in the case. This will do until I put an insert in the hole.

Back to the oil pressure. Next step was to pull the oil pump cover and check the gasket. Then I pulled the cover from the oil pump. I was *this* close to putting it back on sans gasket, but I decided to use a 0.004″ gasket I got from local mechanic. I did not have this gasket before. Ok, added a little grease to pump gears (to help in priming), all the other things all put back on, coolant replaced, oil replaced.

Engine start… cold pressures: idle 70 psi, max 90 psi. Hot pressures, idle 20 psi, max 60 psi, a solid 30 psi at 2000 rpm. Much better. Turns out the gasket in the kit, the one for under the oil pump cover, was 0.012″ thick. Far too thick. BTW, the endplay for the pump gears measured between 0.002 and 0.003″. After driving around for a week I am still not happy with the oil pressure, I think I can do better. Hot idle (after hwy run) is only about 7 psi. I am going to pull the pump cover again and re-install with no gasket, just sealant.

There were other annoyances after install – poor fitting (new) exhaust pipes was the big one, but I won’t bore you with my griping. So here we are, engine in.

A closer shot of how the oil pressure sender relocation manifold fits in. God I hate non-black cable ties.

So after a week or so of driving? Well apart from my lingering concern about oil pressure I have 2 other niggling issues. One is a little oil leak from the engine end of #1 cylinder exhaust push rod tube. Probably no chance of it sealing itself, so I’ll be putting in one of the spring loaded push rod tubes that I found on this engine. I cleaned one up and replaced O-rings.

The second thing is a funny, intermittent scraping, rattling noise. I think the forward exhaust pipe is sometimes rubbing on the skid plate. Only happens with some torque on the engine, and not when revving when van parked.

To finish up this post I’ll mention a couple of tools that made this job a whole lot easier. First one is a bit of a surprise, “The Larry” miniature trouble light. Was given to me by good friend Stephen and it really does do the job. The clip is magnetic so the pen sized thing will stick. Gets into tight places, puts the light where you need it and not in your face.

A set of hose clamp pliers. This is a pretty cheap set but works quite well. Well enough to make you love spring clamps.

This tapered punch came in handy to line up recalcitrant bolt holes on the exhaust and my skid plate/

The job is not completely over, but I’ll say it was a success. Tragedy + time = comedy, I’m laughing now.

Vanagon – front door speaker mounts – painted

Posted by albell in vanagon, vanagon mods on June 18, 2013

A year ago I made some speaker mounts to help hide the torn up lower half of the front door panels, and to mount the speakers more securely. It was a previous owner that installed (and cut some door metal) these speaker and it really wasn’t a very good job. My solution worked out ok, but I tired of the unfinished aluminum look and the speaker grills had been kicked repeatedly and were dented. I can’t really blame anyone for the kicking, the speakers are in a vulnerable spot.

So I pulled them off, took them apart, and reformed the stainless mesh grills back into a shallow dome. Then I painted everything with rattle can bed liner. I think the paint stiffens up the stainless mesh, gluing the wire crossings. I painted some plastic screw cap covers to match.

Original look:

New look:

Vanagon – auxiliary gauges

Posted by albell in vanagon, vanagon mods on June 18, 2013

I installed 3 old gauges, VDO Cockpit series, that I had in my old I4 powered ’82 Westy. It was sure easier to install the senders in that engine, no relocation manifold needed. But on the WBX I had to relocate the stock oil pressure senders so I could add an oil temp. sender and an oil press. sender.

I detailed the sender install in this post. That short temp sender (Beck Arnley part# 201-1098) seems to be the right one, the oil temp gauge is indicating pretty well expected readings. Yeah, yeah, I should have set up some boiling water and tested before installation. But I didn’t, so there.

Hey, if anyone has a mind to copy the aluminum manifold for the senders, give more room between each sender. I put them too close together, wrench access not so great.

The gauges have seen some wear and tear, and I replaced the bezels on two of them with bezels from salvaged gauges from an old Volvo 245 turbo. The bezels are crimped on so removing them means prying with a fine edged screwdriver and you can’t really get that back to factory condition. But from a distance it is not really noticable. During the bezel replacement I dropped 2, yes 2, of the glass faces. What a clumsy fool. I had one spare glass, and for the other I cut a circle of Lexan. I repainted the needles with fluorescent orange paint while I had the chance.

For wiring I used some old computer cable, 6 insulated wires in a grey sheath. Each wire was multi-strandded and the sheath was pretty flexible but I bundled the 3 cables in some black heat shrink tubing and the bundle is pretty stiff. I used a heat gun to warm up the bundle so I could manipulate it into the right route. And that route runs right in front of the padded dash to the corner of the instrument panel cover, where I made a rounded notch and the cable makes a 90 degree bend and a little down to end up close to the right hand side dash support strut. The bundle lays down with no glue or clips after the heat gun treatment.

At the sender end, I used a couple of spare wires from the now removed Webasto BBW46 heater wiring to send oil press. and temp signals up front. For the voltmeter signal I connected to “G5” terminal on the fuse panel (“15” power, ie hot when ign on). For illumination, I tapped into “G8″ (dimmer controlled power) on the fuse panel. To make things a little neater, I used an old terminal strip that has screw connections and used that to connect the gauge wires to the sender wires. This terminal strip was mounted to one of the dash support channels beneath the instrument panel.

The gauge pods were screwed onto a bit of 1/4” aluminum plate, painted black. One day I’ll get some black covers for the screw heads. The plate is glued to the dash with that foam cored double sided tape. That stuff seems to take dash heat better than other tape . The gauges seem to work fine, I didn’t confirm the oil temp or pressure with another method, but the values I see look reasonable.

Vanagaon – Q and D head replacement – quick update

I’ve had the engine installed for a little over a week now. I’ve had some niggling problems and I will write about them, but for now here is a crude little video of the engine running. Proof that I actually completed the job 🙂

(dirty lens, sorry. Oh the dipsy-doodle to the exhaust pipe was to try to record a bit of the exhaust note. Since the new exhaust pipes have been installed, my home made muffler does not sound as good as it did with my leaky exhaust. Wait, what? I dunno)

Vanagon – Q and D head replacement – closing in

A few more odds and ends before the engine goes back into the van. In no particular order…

My diff lock light has not been coming on for a while now. I narrowed the cause down to either a broken wire, a faulty switch on transmission, or a bad connection at switch. I had planned on pulling the switch, but as I didn’t pull the tranny with the engine, and as is (ie the vacuum actuator still attached to tranny) I could not get a wrench or a socket on the switch to remove it. See how tight (ie little clearance) it is?

So as I stand there, kicking myself for not pulling tranny, I decide to cut open the bundled wire sheath to see if there is a broken wire where they make some tight bends. No luck, all is good, so I pull back the rubber boot on the connector and one wire comes with it. Did I just pull it off or was it broken already? Of course I am pumping for the latter. I fixed the connection and put it all back in place. Fingers crossed.

I forgot to mention before this that I found a bent pushrod when I took the heads off. If I remember correctly, it was on the side with the (leaking) spring loaded pushrod tubes. How does a bent pushrod affect the engine if the valve adjustment is done correctly?

I’m re-using the clutch drive disk and pressure plate and I measured things to check if that was a good idea. There is still some good life in the disk and the pressure plate has all its finger and is flat. The flywheel is ok too, I de-glazed with fine emery and I replaced the O-ring. The old one was quite stiff.

I did some head scratching when it came to the support bracket on the rear exhaust manifold. Seems that the syncro muffler carrier has extra holes in it to attach the bracket. As I have home made aluminum muffler carriers I had to drill some new holes. Pretty tight, not much wrench clearance. I’ll curse myself if and when I have to get the bracket or carriers off.

Boy am I happy to see the engine finally in this state.

Oh, and when I was in the engine bay I looked into the holes in the frame members on either side of the bay. The frame members that further back house the bumper mounts. A lot of dirt in there.

Next job is to move the engine from the stand to the hoist so that I can get the flywheel and clutch back on.

Vanagon – Q and D head replacement – A little update

Life, god bless it, intruded on the project a bit. So really not much progress to report, but what I have I give to you. (sheesh!)

Way back when, I played around with an oil pressure switch relocation set up. I blogged about it here. I saw no reason not to whack it onto this engine. Some notes about the install:

– threaded hole between the pushrod tubes, where one of the 2 oil press. senders originally fitted, is M10X1.0 thread. I used a brass adapter, male M10X1.0 taper thread by female 1/8″ NPT. Note that I have got a male taper thread going into a female straight thread. I was assured that this will seal up fine.

– Then from the female 1/8″ NPT we go to 1/8″ soft copper pipe via a compression fitting. A better way would to be to go to brake line rather than copper, more vibration resistant.

– copper line sheathed in fuel line

– stainless steel cable tie securing line to pushrod tube. Not really needed, the line is pretty solid in it’s run (the covering stiffens things up a bit). I worry about the tubing vibrating and putting stress on the compression fittings, but as it is, the tubing is routed pretty nicely, tight and secure.

– the line runs up tight to engine case and out to the top surface between case and thermostat housing.

– I had to use a 45 degree 1/8″ NPT female to male to make the turn. A 90 degree fitting was too tight. Then we have another female 1/8 NPT to male M10X10 adapter which goes into the manifold.

-due to that little pipe that goes from water pump to Tstat, I had to make a little spacer to raise the manifold about 2 cm.

– that side pushrod tube protection plate had to be reworked a little. I’ll get a pic of that sometime.

At the rear of the engine, just to the right of the water pump, the now vacant M10X1.0 hole (which is actually a reduction bushing) can have a temp sender probe fitted. I had this nice VDO sender (used it for years on my I4 engine in my ’82 westy) and popped it in there. Later I broke the bugger when I Was going round checking that “I had tightened things up”. Bloody hell. Local autopart stores could not get me a new VDO sender anytime soon, so I took a chance went for this sender (MKII/MKIII Golf). I don’t care that it is shorter and not reaching as deep as the other one. Well I do care but will it *really* make that much difference? Pic showing senders and reduction bushing.

Installed in engine. Signal wire running up then back over top of engine and I’ll bundle that up with the oil pressure sender wires.

Remember my rotted coolant pipe? Well I found another. less rotted one and decided to patch that one up. It had one hole in the main pipe and another one in one of the side pipes. I brazed the holes closed and then slopped on more braze to fill in some minor pitting. That pipe, especially just at the bend where it comes up to connect to the Tstat housing is very exposed to the elements and heat from the exhaust pipe. The combo of heat and weather causes the paint to be eroded and the pipe to corrode. I had the idea to weld on some tabs to allow a little shield to be installed, but I had blobbed on the braze before I remembered and the TIG welder was being used on some serious stainless welding so I left the tabs off. I might try and clamp on a shield. Not the best way, the clamps might be a locus for corrosion starting. I painted the repaired pipe with POR 15, and then with some orange engine paint.

I encourage those of you with old 2.1 WBX engines to check this pipe. Poke at it with a screwdriver or an awl. Make sure it is not on the edge of failure.

I have to say that this project has been much more work than I thought it would be. I not regretting doing it, my god the rotted coolant pipe alone has made it worthwhile. But I have been distracted and unable to concentrate during the job and that is annoying me.

More to come, this job will end 🙂

Vanagon – Q and D head replacement – surprise

Catching up on my progress. I spent yesterday (Sunday) adding the bits and bobs that go on the motor. Intake runners and plenum, coolant lines, oil cooler, PS bracket, alternator bracket, dipstick, etc. A bit of a disappointment when I fitted up the spare rear manifold and found that the end did not line up with the end of the new front manifold. Not even close. I thought that the rear manifold was the same for all 2.1 engines (apart from, perhaps, the small support clamp and bracket) but this one was nowhere near close to working. The angle at the end of the pipe where it meets up to pair with the front manifold was all wrong. I bought a new one today and it works, but needs some slight adjustment.

But the real surprise yesterday was the coolant pipe that runs from the water pump forward along the left hand side of the engine to connect with the thermostat. I had forgotten all about it when painting other bits and yesterday, when I was going at it with the angle grinder powered wire brush I uncovered this.

Wow eh? I think the paint was all that was protecting me from a massive coolant leak. Talk about lucky. This one discovery almost makes this entire ordeal worthwhile. I’ll talk about what I did about this in a later post. One more pic, before I put the rear manifold on.

A personal issue has complicated things, but I hope to get this thing done in the next few days.

Vanagon – Q and D head replacement – am I winning?

It has been a bit of a chore.

I can’t recall if it was last Friday when I updated last, here goes with a catch up of what I did on Saturday. I think it was Saturday, my weekends and evenings are so filled with gallery openings, theatre premiers, cocktail parties, and the occasional orgy that I often lose track of time.

First off, a pic of how I keep the cylinders in place whilst rotating the engine on the stand.

Removing the head from cyls 3 and 4 was difficult. The heads were stuck fast. Lots of tapping with brass drift got #3 loosened, but #4 was a real bugger. I finally got smart and ground the end of my pry bar so it had a sharp edge to catch on the tabs on the cylinder top, final pry and it was free.

Oh that thin green O-ring at the top of the cylinders, not doing much now eh?

Digging it out (dental pick).

I was getting on fine with the clean up, then disaster struck. I inadvertently, or stupidly (take your pick), pulled #4 cylinder up too far and the bottom (oil) ring came out from the cylinder. “Oh darn it” I said.

Over the next few hours, during which I had no inclination to take any pictures, I pulled the cylinder right off, removed the wrist pin on #4 and took piston out, decided (rashly) to pull #3 cyl too but left that piston on con rod. With them on the bench it was easy to really clean the cylinders. And I was able to clean up #4 piston.

Ok, back to assembling rather than taking more things apart. I used a regular sized ring compressor to get #4 piston and cylinder together. Oh and I cleaned and polished #4 wrist pin, even so it was still a tight fit.

I cut down another of my ring compressors so that the compressing band was about 5 mm wider than the distance from top to bottom piston rings. This particular spring compressor could be taken apart. The head bolts and water jacket restricts access to #3 piston even with #4 piston and cylinder removed, bit the compressor worked like a champ and I got the cylinder over the piston first try.

But… when I was removing ring compressor a part of it fell into the open spigot of #4. “Oh gosh darn it”. The piece was aluminum and my Al magnet was at work. Rotating the engine didn’t work. I finally pulled #3 cylinder again and the lost part was tucked under the piston skirt.

Ok, again, cylinder back on, compressor removed very carefully, then the assembled (on bench) #4 piston and cyl brought over to do the gynecological insertion of wrist pin through water pump and into (flopping around) con rod. VW has a special tool to hole the cond rod in place, but I did it by getting the engine rotated on stand “just right” so con rod hung in position.

Phew!

Pic taken just before all that.

And after things back together. Also replaced black O-rings at bottom of both cylinders.

Back on the heads, using a spare cylinder I “lapped” where the cylinder meets the head.

Fine carborundum powder, oil, and twisting the cylinder back and forth. Then I cleaned up the heads, blasted with compressed air, re-installed valves (gave them a little lap love too), then degreased the surface where the rubber gasket seals.

Then on to the oil pump. What stalled me here was trying to remove all of the old paper gasket. The paper was really stuck on and one did not want to scratch up the mating surface. The endplay on the pump measure out to 0.002″ (wear limit is 0.004″) so I decided to use the new thin gasket during re-assembly. Some say to use just some sealant if endplay is close to wear limit. I lapped the pump cover to remove the pump score marks, don’t know how useful that is.

And now the rubber gasket. I used the Reinzosil sealant that came in the gasket rather than “The Right Stuff” (and I do have a tube of that). Why? Well why not? All accounts are that it is good stuff, improved from the original. A thin bead applied to the grooved side of seal and the seal placed on the water jacket. Then a thin bead down the centre of the mating surface.

Then the head….

Cleaned up pushrod tubes, checked them for length so they would have good “push” when compressed, put on new seals. Clean and dry holes in case and head.

I used cap nuts on 2 centre bolts to pull the head down (compressing pushrod tubes) enough to get the rest of the cap nuts on. Yellow sealant applied to the head rather than the base of the nuts. It all went rather easily. Torqued the head down in 3 stages – 10, 25, and finally 40 ft/lbs.

I numbered the cap nuts in torquing down sequence. I was nervous, numbering the caps calmed me down 🙂

And I got the other head on with no drama. I had to check the fit of my new exhaust manifold (Dansk) and it fit up to the heads as if it was made for the job.

Then I started putting things back on. A cleaned up, inside and out, breather tower with new O-ring, new waterpump, and one newly painted coolant pipe.

Enough for this post, I’ll try and catch up on my progress in next post.

Vanagon – Q and D head replacement – progress

I got somewhere today but realised that there is much more dirty than quick in this chore. I transferred the engine from hoist to stand then set about taking off all the ancillaries.

This pic shows the backside of my muffle mounts. Also shows my stainless steel flex hose repair to exhaust pipe (I whacked it badly on a logging road over a year ago).

More exhaust shame. I’ve re-kludged the end connection of that pipe many times over the years. Oh frabjous day when the new pipe goes in.

Example exhaust stud.

I mentioned previously that I noticed that my water pump was going fast. The pully and shaft was loose, and here you can see how the shaft looseness has allowed the impeller to score the pump body a bit. I don’t think this will affect the function of the new pump too much. BTW, even with the engine on a stand, getting the water pump off is not easy. I would not like to do it on the van.

The oily side of the engine. Hello, what’s this? Spring loaded pushrod tubes. I don’t think they worked very well, evidence of oil leakage especially on the one closest to camera.

I’ve kept the oil breather tower on during all this, just to cover the hole to the crankcase. I replaced the O-ring at the base of this tower about 2 years ago, but it has been leaking badly. I think I’ll re-install with some oil resistant sealer plus new O-ring.

Another view of that oily head. My god there was a lot of baked on crud to remove. I used a putty knife and old screwdriver to scrape the worst off, then some solvent and brass brush. I wasn’t trying to get the engine pristine, just to be able to work on it without getting angry 🙂

The dry head. Normal pushrod tubes here.

Time to take off a head, starting with the oily one.

I used some aluminum welding wire and tags to ID the pushrods. Does it *really* matter if they go back int he same hole? I don’t know.

The head nuts removed and the head rapped in various spots with a dead blow mallet. Then I could pry up the head a tad, remove the pushrod tubes and see to my dismay that the cylinders were stuck to the head. It took a fair bit of hitting with a brass drift and hammer to free the cylinders from the head. I only lifted up the head about 7/8″, just enough to get the drift on the cylinders. Prying on those tabs you see in the pic was not effective. I hope the bottom of the cylinders seal again, I believe they do, but… I have the feeling I will pull them and replace the seals down there. Grr.

Tops of pistons. I don’t know what normal, good, or bad is supposed to look like. I was happy to see the water jacket edge was not corroded.

And the head. The black stuff does note really look like sealant. Perhaps it si a mixture of corrosion and Holts Stop Leak. The exhaust valves look different than the ones on my replacement heads. These have a depression in the middle, the others don’t, just a small dimple. Now which type mean sodium filled stems?

Close up of the crud on the head. And do you notice the yellow paint on this head?

Closer look at valves, is that a crack between them?

Sure looks like it is.

Well there you have it, today’s work. I’m not getting it done as quickly as I thought I would (doh, when will you learn? Ed.), but it is getting done. Tomorrow I hope to get other head off and then start on the re=assembly. Will be so nice to put some clean parts on the beast.

Vanagon – Q and D* head replacement – engine out

*Quick and Dirty

Took me a while to do it yesterday. I had to clean up some of my mess to make room in the workshop, and I got confused and stalled by what to do with the heat shield that runs across the rear of the engine compartment about the muffler. I didn’t notice right away that the holes in it for the screws holding it to the van were actually slots, not holes. And I had one screw that would not come out (I ended up die grinding the head off). Turns out the shield comes off with the engine – so there is no need to spend time trying to take off the oil filler tube (plastic part does pull off with a little help from heat gun), or to take off the metal coolant pipe that runs from water pump to T-stat. I thought I had to do all that to gain some space rear ward so I could pull the engine back and off the tranny.

What’s that you say? I thought you were pulling tranny and engine as a unit? I did plan on that, then I realised that if I allowed the tranny to drop 4 inches or so (as described in Bentley manual), I could reach the spots on the tranny that I wanted to deal with (starter electrical connections and diff lock light switch). Leaving the tranny in meant I didn’t have to fuss with CV joints or clutch slave cylinder bleeding. But after all the time I spent trying to get the engine back off the tranny I am not sure I saved any time at all.

A couple of other excuses – no lift/hoist and tight working space. Ok, I agree, lame.

Anyway, the dirty oily thing is out and hanging on the hoist (engine was lowered by hoist and pulled out from under van as it was resting on hoist base). Today begins with shop clean up and transferring engine to work stand.

Here is the engine pretty well ready to be removed.

And out.

Tranny is resting on blocks in this shot and van rear is raised high to allow engine to come sliding out. No stress that I could see on tranny connections, but van lowered back down after pic taken. I was concerned about stress on CV joints, but I don’t think I’ve subjected them to any great angle.

Vanagon – quick and dirty head reconditioning

In my last one before last post I mentioned that I had been given a Subie 2.5 engine from good friend Simon. The engine needs to be gone over carefully before using and because I work so slowly and also because I am still not 100% convinced about putting a subie engine in the van (don’t start, I know my feelings are irrational) it won’t be going in my van any time soon. But I need to fix things on my current WBX engine, namely a rotten exhaust and a weeping headgasket (cold weather weep on one side).

I have a spare WBX, of unknown provenance, and I decided to take the heads from it, clean them up, and pop them on my current WBX. At the same time I can replace the parts of the exhaust system that have rusted away and also replace some seals and gaskets.

So I took the heads off that spare engine and noted that one head had some pitting and corrosion, the other looked like it was a newish addition. Both heads checked out ok in regards to valves and valve guide tolerance. I set about filling the pitted head with some JB Weld.

Here is the pitted head after a quick fly past with a sand blaster.

JB Weld smeared on the pitted areas.

Head weighted down on parchment paper on a marble slab.

After the JB Weld had cured.

100 grit sandpaper glued to marble slab and head being “lapped”

The result.

All the pits now filled with JB Weld. Even the ones in the pic that still look unfilled.

The other head, looking pretty nice.

And with its old gasket. A lot of sealant squeeze out, note that the sealant had blocked hole on upper left hand side.

Gasket flipped, squeeze out apparent, as is the “cast” that blocked the hole, now on the lower left hand side.

I’m taking the rest of the week off work (well work is slow anyway) to drop my engine and tranny and get these heads and the the rest of the needed stuff on.

Vanagon – small finds at the auto wreckers

Posted by albell in vanagon, vanagon mods on May 15, 2013

I had the afternoon off so I drove up to Malahat Autowreckers to see if there were any new Vanagons in stock. And indeed there were, 2 1990 MY passenger vans that were not completely stripped. One was a weekender, driver’s side jump seat and table still intact. Both had something I had not noticed on a Vanagon before, an aluminum sill plate on the sliding door entrance. I bought one, here it is.

The part number is 255 853 558. I think it is available from VW Classic parts, “scuff plate – sill panel- Einstiegleiste”,

Back side:

I also managed to find a couple of undamaged cup holders.

And some fairly new looking front door inside latch plates (they really get ratty, especially the brown ones), and a couple of surrounds.

A few relays and clips rounded out the shopping spree.

Vanagon – misc. updates

Posted by albell in vanagon, vanagon engine swaps, vanagon mods on May 14, 2013

I haven’t been posting much recently, work and garden chores have been taking my time. One good thing about the work time is that my welding is slowly improving. Helps having a good teacher and access to the best equipment. One day I might be able to make a good aluminum weld that is more than one inch long.

But some things are happening on the vanagon front. First off, I replaced the LED light strip on the rear of the lower cabinet, doing away with the pierced moulding experiment. Mainly due to the fact that 6 LED elements failed on the initial install, but also I didn’t like how I drilled the holes. The LED strip is in an anodized aluminum channel

Staying with LEDs, I installed a couple of feet of strip above the footwells of the front seats. They are wired to go on with the doors opening. Not the greatest mod in the world, but fun to do.

When I was younger I thought that ski boxes, or coffins as I dismissively called them, were stupid. But what do you know, I’ve changed my mind and I found a really old school Thule Combi-Box 250 for sale for $50 and I bought it. So why the change of attitude towards these things? In a word, chairs. Yup, I’m fed up with stowing the folding camp chairs behind the back seat. Now they will go up top, and the fishing rods too. I haven’t mounted the box to the van yet, I still have to make some modifications to my roof rack attachments so I can get the box on the right spot on the roof.

The bigger news is that I was given a 2008 Subaru EJ25 motor. Good friend Simon had it in his ’91 syncro and it had been making a brapping clstter upon acceleration. All kinds of things were tried to stop the noise, none of them worked and the final opinion that it was perhaps a rod bearing. So he swapped in another engine and gave me the suspect one.

The generous gift has put me on the spot about future engine transplant. I really have a soft spot for VW inline 4 engines. I had one in my ’82 van (1800 Digifant) that ran flawlessly from 1994 to 2009 (van got T-boned and written off). I’ve been nursing the idea of a 2.0 litre I4 in the syncro. I have all the parts needed except one of the big ones – a diesel gastank. The starter in the 12 ‘o’clock position with the diesel bellhousing so it needs a differently moulded fuel tank to clear the starter. Those tanks are not so common over here on the northwest coast of North America so I haven’t been very quick to get an I4 installed. My dawdling and initial lack of interest in my stock WBX engine has resulted in me not doing much about keeping my current motor in good shape. Bothe the front and rear exhaust manifold need replacement, but the studs.bolts holding them on to the head are really rusted and decayed. I know that they will be hell to remove. Plus I have a slight coolant leak on one head (happens during cold part of winter) so it means some sort of head work even without the exhaust problem.

But then again I have a spare WBX engine that I have been just dicking around with. Why don’t I take the heads off it and see if they are good enough to use on the van’s engine? That way I can replace the exhaust manifold and head leak relatively quickly and keep the WBX in my van running long enough for me to get the Subie engine attended to (or get and I4 built up :)).

I had to drill out a couple of the exhaust studs on the spare heads, nothing, not even oxy-acetylene heat would budge the buggers. One of the drilling out operations went awry and I had to fill the hole by tig welding then re-drill and tap.

So far the heads look usable. One head has pitting, the other does not, just a hint of some corrosion beginning.

The two heads, I took a wire brush to one, and removed one set of valves (valves check out ok, and within spec on fit in valve guides).

Close ups of the pitted head.

Doesn’t look like any crack between the valve seats.

But is that a casting mark or a closed crack? I don’t think it is anything to be worried about.

The start of some corrosion on the un-pitted head.

And example of what the rest of the sealing surface looks like.

So I’ve got these heads, a gasket kit, a new front exhaust manifold and a used rear manifold. The plan is to drop the engine and tranny (I want to fix the diff lock light switch on the tranny, easier if tranny is out) and swap over the heads etc. I hope to do this in the next couple of weeks.

Vanagon – interior LED lighting update

Posted by albell in vanagon, vanagon mods on March 29, 2013

In this post I described installing some led strip lighting and dimmer switches. During the install I smoked one of the dimmer switches so I wired both strips to the one controller and lived with it until I ordered another switch. Those dimmer switches were inline units and I spent some time milling out a kind of mounting plate for them. The more I looked at this kludge the less I liked it. It didn’t help that a couple of friends were less than enthusiastic about it, despite my glee at actually being able to make the thing. Looking around superbrightleds.com I found a better solution, this dimmer switch. All it does (capacitance touch method) is turn light on and off and dim them. The previous switches had additional flashing and flicker settings which really are useless in this application ( I thought perhaps the flicker setting would mimic candle light – ha! was I wrong).

The new switches come with 5.5 mm barrel connectors so I also ordered up some adapters so that I could attach wire pairs. I installed the switches today and I have to say they are a big improvement over the other ones. One touch turns the light on or off (and the light ramps up and down with the on and off touch – a small feature but very cool), and holding your finger on the switch dims down then back up. No moving parts, its all to do with capacitance (David B. needs to explain this to me).

No points for guessing where the makers got their design influence from.

The male and female 5.5 mm barrel to wire adapters.

The wires go here 🙂

Adapters on the switch leads.

The switches come with a small square of 3M adhesive backed Velcro. Makes them dead easy to mount, but not dead easy to get two of them perfectly aligned.

Addendum: I just measured the current draw of the new switches. When turned off my Do Wattson shows 0.00 A. When both main cabin strips turned on the meter shows 670 mA. This is better than the old switches that did consume a little power when off (somewhere under 10 mA) and when switched on the system drew 750 mA.

Vanagon – platinum catalyst heater mount

Posted by albell in vanagon, vanagon mods on March 26, 2013

Yeah, I know, I know, these heaters are not the best solution for the van. I got this one back in ’93 and never did install it in my ’82 westy. But over the last couple of years I’ve dragged it out to use in the syncro for winter camping, and last week I finally cobbled together a more secure mounting system for it.

BTW, apart from the risk of oxygen depletion, and the possibility of CO production (although if the heater is working properly little CO is created, well except if the oxygen level is low then more CO is produced) the big drawback of an unvented propane heater is the production of water vapour. Here’s the logic, using a 1 lb propane bottle as fuel source:

combustion equation:

C3H8 + 5 O2 —–> 3 CO2 + 4 H2O

so for every mole of propane burned, we get 4 moles of water.

the molecular weight of propane is 44 g/mol, and therefore a 1 lb (454 g) bottle contains 10.3 moles (454/44)

So burning the entire bottle would produce 4(10.3) = 41.2 moles of water

The molecular weight of water is 18 g/mole, therefore 741.6 g of water produced.

A respectable amount, almost 3 cups, of water is liberated into the van when you burn a one lb bottle of propane.

So the lesson learned is either buy a vented heater or make sure you vent the van well. I like to have the pop top vent partially open and one window open about an inch when I use my unvented heater.

OK, enough. The point of the post was to show my quick and dirty mount. I used scrap 1/4″ aluminum (5052 if you’re asking) and instead of welding (my skill at welding inside corners, especially on tubing is still at the crap level) I bolted it together.

The heater.

The unpainted aluminum shape is bolted to the heater to stiffen things up. The painted “wing” is the bolted to that stiffener. The bent tube is actually bolted to the wing – bolt through wing into a tapped hole drilled crosswise in a bit of steel rod which is running crosswise in the tube. Oh yeah, that’s great descriptive prose. One unexpected bonus is that the heater now can be placed on floor, if desired.

Unpainted end of tube fits into front table arm of the van. It can be adjusted to a range of positions and is high enough to mostly avoid being hit by the dogs.

I’ve been using a 20 lb propane bottle sitting in the driver’s footwell. No, not the most elegant solution.

Addendum – it just occurred to me that it might strike some as strange that I don’t simply attach the tubing directly to the stiffener piece and get rid of that black wing. The truth is I made the tube and wing first and mounted it directly to the top two bolts on the heater. But I found that not steady enough so I made a backing plate. I liked how I could coil the propane line around the wing, so I kept it, for now.

Trip – stopped by snow but fun anyway

This past weekend my wife and I headed off for a quick overnight trip. We didn’t plan a destination, but ended up, again, in the area north of Port Renfrew. Snow level was much higher than it was back in January, and we managed to get up Grierson main and we had hopes of getting to the viewpoint we visited last May.

But the combo of thick crusty snow and a steep final approach thwarted us.

No really, it was steep.

We really wanted to get to the end of this spur, but no way. Just above that steep section the road flattens out.

What it looked like last May.

And this time.

And the spur we wanted to camp at, as it was last May.

And this time.

Our fire pit was still there.

So we went back down the road about 200 metres.

Wasn’t too bad, sunshine and a nice view.

Walked down the road a ways and looked at the desolation after logging.

If you look closely you might be able to see the yellow shoots of Skunk Cabbage poking up at edge of the water.

Pretty little oasis amongst the logging.

One of our dogs, loves the snow.

Cape Flattery, Olympic Peninsula, Wash. State.

We had the Go-Westy rainfly up, and the Westy pop top insulation blanket installed inside. We also brought along the Olympian Plat Cat heater (not used when sleeping). The set up worked very well, and with the pop top vent cracked overnight, we have very little condensation on the windows in the morning. Must have had some sort of chimney effect going.

A little bit of snow falling next morning.

Breakfast, and the tell-tale sign that someone in the family is a Molecular Biologist.

The old “Excelsior” at work again.

The dogs taking up space.

Then off we drove to explore more of the area. The weather cleared a little, if it wasn’t for the wind it could almost be described as mild.

Nice little lake, second growth forest.

Edinburgh Mt. in the background, steep logging in the foreground.

And wouldn’t you know it, we even checked out the Camper Creek area campsite that we spent so much time at last summer.

Ooh, kindling!

Notice how the mirrors take a bit of a lashing on these trips?

Came back home via Gordon River and Cowichan Lake (a round trip we have done many times before). Saw signs of kayakers along the Gordon – crazy folk who paddle down the canyons.

Vanagon – an interior led lighting project fail

Posted by albell in vanagon, vanagon mods on March 16, 2013

It’s not hard to guess that I am enamoured by led strip lighting, but my latest project using the strips is a (qualified?) fail. I’m posting it just to make it clear that I often go down wrong paths.

I had some led strip left over from the step protector project, and I wanted to get some light back at the hatch area. Sometimes we sleep with “heads at the hatch” (more of a summer rather than winter position, but what the heck do you care? :)) and It would be nice to have a reading light back there. A light also could be useful for finding stuff in the dark etc. So how to mount a strip of led lights back there? Well of course a bit of aluminum channel screwed to the back edge of the ceiling – in place of the T moulding – would be the way to go. But I decided I was smarter than that.

I took the T moulding off and went about hacking it up to install the leds actually in it.

The Westy T moulding.

The led strip, looks like it will fit behind moulding if T was removed.

After some false starts, I found that my die grinder with a ball end bit cut the T off nicely.

Ok then, done.

The next part was to drill holes for the leds to peek through. Now I don’t know what system the makers were using to space the led elements, certainly they weren’t thinking about me laying out for drilling. And, every so often the spacing changes as strips are factory joined together. Grrr, I had to drill holes larger than I wanted too. But I kept on going down this path and I glued the led strip face down onto the T moulding.

Right then, after the glue had set I took the strip out to fix it up on where it used to be. I have no pictures of the shambles that followed, but imagine the floppy strip, Sikaflex, no real locating mechanism to keep strip from sliding sideways, spring poles that kept falling…

But up it stuck.

It looks much worse in real life. Here is side view.

So what are those aluminum bits at either end? My attempt at hiding areas where the laminate had chipped off the plywood (nothing to do with this project) and to securely hold down the ends of the modified moulding. During the project I had glossed over the question of what kind of switch to use and where to mount it. I tried but came up with nothing better than this switch mounted on a little but of angle glued to side of upper cabinet.

It is not great I know, but there you go. And switching on…

Bloody hell, 3 leds out. I’m sure that when I tested the strip before gluing it on to the cabinet all of the leds worked. I’ve resolved to rip this out and re-do using aluminum channel and new led strips. Will the night time shot make me feel better?

Couldn’t wait until full dark, pics taken at dusk. First one, light off.

And light on.

The pics don’t do it justice, there is certainly enough light to read by. And enough to really show up the dirty marks on the fabric attached to the hatch (it is about 12 years old now). All in all I’m pleased with the light, I will redo the mounting, but damn those failed leds!

Vanagon – “step protector” project

Posted by albell in vanagon, vanagon mods on March 12, 2013

Just over a week ago, Psyncro aka Syncronoid posted a clever mod on this Samba thread. I slapped my forehead, doh, why didn’t I think of that? So blithely I set about making my own version. I have an abundance of scrap aluminum left over from various projects/jobs so I figured I could knock one out in a trice.

Ha!

I cut some 2″, (3/16″ thick) angle to size, angling the ends to match the rubber mat I have over the carpet in the walk through between the front seats. BenT suggested I do something to make the top surface more interesting, so I clamped up the angle in my lathe’s little milling head and cut some 3/8″ wide grooves. The milling head does not have enough travel to do the cuts in one go, so the angle has to be repositioned during the cut. That, and my rushing, produced a sloppy effect.

So I decided to paint it with satin black Krylon. What was I thinking? I forgot to prime (zinc chromate is common primer for aluminum, strontium chromate is the better primer but hard to get). No primer meant the paint scraped off easily, not a good thing for something that would be trodden upon.

Then I had the idea of filling the grooves with some 2 part polyurethane. Do you get the idea that I am spending too much time on this simple project?

I mixed up a batch and poured it on.

Then squeegee’d off most of the excess. BTW, it is sitting on a plug-in battery warmer blanket to help the polyU cure. I was getting sloppy, the stuff got everywhere.

And whaddya know? The polyU did not go off, no curing. Expiry date on package is for later this year, bugger it, so I wiped the mess off. On the Samba thread Doug suggested LED lights, seemed like a good idea. I had bought some LED strip lighting (warm white, 30 LEDs/meter) from Lee Valley and at the time was a little disappointed that the strip did not have a clean silicone-like cover like the strips I bought for the interior lighting and glove box lighting job. But the strips with their exposed and projecting LEDs would work great on the step. I drilled a bunch O’holes, same spacing as the LEDs on the strip along the bottom edge of the vertical face of the angle. I also drilled 3 holes for mounting screws then painted the angle with some Dupli-Color bed liner. Then I painted it again to get rid of the thumb prints when I grabbed as it fell off the painting block I had it balanced on.

After the bed liner dried, stuck on the LED strip using some of that foam type double sided tape (with holes in it too, of course). You can see the 3M name on the backing tape of the LED strip, I left this on.

I used some big-ass 1/4″ stainless sheet metal screws. Pan head, as I did not counter-sink into the angle. Why you ask? Well when you countersink you have to get things lined up pretty exactly and as I was match drilling through the angle to make holes in the van, and as the angle is sitting on a rubber mat over carpet over insulation, I did not think I could push down on the angle firmly enough as I was drilling to get a good tight fit. Using pan head screws and oversized holes on the angle allows me to push down on angle after holes drilled to get a tight fit of angle to floor. Man, that was a wordy and awkward description.

I have to blacken those screw heads.

And the LED feature? I don’t have it wired into the door switch yet (I’m thinking about adding an additional switch so I can turn it on independently), but I hooked the leads up to the battery and…

All the trials and tribulations of this job vanished at the speed of light when I saw this. It is better than I thought it would be.

Vanagon – insulated window blanket prototype

Posted by albell in vanagon, vanagon mods on March 10, 2013

I bought some material a week of so ago with the idea to try making an insulated window blanket. At the fabric store I found some brownish-red microsuede material that was deeply discounted, and some “Insulbrite” sorry, “insulshine”. foil faced polyester batting material (about 1/8″ thick). I also bought some 1/2″ diameter, 1/10″ thick rare earth magnets. Today my wife sewed things up (and very nicely too) and I think it works out well.

The idea was to be able to have the shiny side in for winter camping – keep the heat in, and the shiny side out for summer camping – keep the solar gain down. I had thought about using snaps to fix the blanket in place but magnets seemed more versatile. I think it turned out well.

I’ll post a bit more on the construction later.

Vanagon – led lighting the glove compartment

Posted by albell in vanagon, vanagon mods on February 24, 2013

I was in an unsettled mood today, my plans to help good friend Simon add some shims to his syncro were scuttled by unforeseen events. Spent some time with my falling apart dash cluster, trying out a new UV led, but that made me feel worse – the cluster foil is in such bad state that I fear the next time I go in there I’ll really be forced to do a hardwire. So I looked around for an outlet for my angst and I fell upon the 10″ bit of led strip left over from the interior light install shown in last post (on the kitchen side the 2m strip had to be trimmed to fit).

I had this idea to wire it in parallel with the small light above the glove compartment and placed so it would light up said compartment. And I didn’t want to dick around and fuss with the install, so what follows could have been done better.

Look up the Wikipedia entry for glove compartment. I draw your attention to the last paragraph, more proof that the Vanagon was a car ahead of its time.

Most led strips can be cut on the indicated lines (drawn on face of strip), at the cut area there are soldering points. I soldered a couple of wires to those points (nice tinned, teflon insulated wires).

Then some heat shrink.

Polarity is important, that’s why I have both wires the same colour . There are tiny +/- markings on strip, but you can confirm with 12 V power source (I’m fortunate to have an adjustable DC power supply. It is very handy for this sort of dicking around). The positive wire was soldered to the long contact strip on the little light that mounts above glove compartment (what the heck is that light called anyway – Courtesy light? Vanity light? it’s a Map light according to BenT). The negative wire was soldered to the other contact strip. Yes, soldered to the strips. As I said, I wasn’t feeling like doing it kosher.

The strip and wires were fed through the light opening and the light popped in after. The strip has self adhesive backing, and I stuck the strip up under here (sorry about focus).

And how does it work? Some daylight pics to show.

Light off.

Light on.

Well what did you expect? Fireworks?

🙂

Just to be clear, the led strip is now switched on and off via the “courtesy light” or whatever you call that little light above the glove compartment. (BenT: It’s a map light, you dolt)

Vanagon – interior lighting with led

Posted by albell in vanagon, vanagon mods on February 23, 2013

I’ve been wanting to have some led strip lighting in the van for a while but never got around to ordering any online. But a few weeks ago I found some led strips at local hardware store and even being on sale they were pricey ($43 each), but I fell for them. You can do much better price-wise online.

The strips are 2 m long each, with 60 smd leds per strip. That’s a good led density for this application. Calling leds “warm white” is so subjective, a little better descriptor is colour temperature, and these were listed as 3500 K correction, 3000 K. The strips came with a small inline transformer to change 110V AC to 12 V DC. We don’t need that for the van, but we do need some sort of switch. I decided on an inline dimmer/controller from Superbrightleds.com, this one. I ordered 2, one for each strip. When they arrived I realized that perhaps an inline dimmer is not the best way to go, would be better to have a wall mount. Time for some metal butchery. The same old thing with me, going the long way around.

A bit of 1/2″ aluminum.

I really just eyeballed the milling (used the wee milling head for my lathe).

Then a half hearted clean up. I need to get a better countersinks, see the chatter marks in the holes, especially the mounting screws?

And the dimmers added.

The milled slots use now clear. Can I draw your attention to the black heatshrink on the ends of 2 pairs of wires? I forgot to remove one of them, grr.

I secured the wires to some extent with some Goop. The heat shrink job was redone a couple of times after this, you’ll find out why.

And installed on top front inside corner of the wardrobe. I figured I could reach the dimmers when lying in the lower bunk.

The leds strips were installed in two places: one on the underside of the kitchen trough so that it pointed straight down. The other on the angles face of the slider door valence. The latter shines in and down. So I wired the strips to the dimmer and during the process forgot about one of the heat shrunk wire ends, and I shorted one dimmer which let out a little magic smoke. Stupid mistake eh? I left the broken dimmer in place and re-rewired things so that the remaining dimmer controlled both strips. Troubleshooting this screw up resulted in re-doing a lot of connections, sigh.

This pic makes the slider door side strip seem brighter and more glaring than it actually is.

The kitchen side strip has no real glare, I’m guessing the beam angle of the leds is about 120 degrees.

I’m very happy with the amount and quality of the light these strips make. I’d like to add more, and maybe even some RGB strips and a colour mixer.

Addendum : I forgot to mention how much power the lights draw – if I recall correctly it is around 4.8 W per strip. I know nothing of how PMW controllers work, ie how much power is used by controller and strip when light is dimmed down low.

Another addendum:

I did some measurements with my installed Doc Wattson. Measuring current flowing from my aux battery.

first, van as is:

leds off, 1W, 85mA

leds full on, 9W, 750mA

leds dimmed lowest setting, 1.7W, 140mA

Radio face plate off:

led lights off, <0.1W, <10mA

For interesting comparison, kitchen water level/battery meter panel on, led lights off, between 0.2 and 0.3W, between 20 and 30mA.

So the led dimmer control draws a little power even when off, but it is less than the “switched on” kitchen indicator panel.

So the led strips, both sides combined, only draw 140mA power at lowest brightness. And that low setting is pretty good for a standby/casual use light.

Vanagon – dash/glove compartment light minor mod

Posted by albell in vanagon, vanagon mods on February 20, 2013

Those of you that have the little light above the glove compartment know how easy it is to ground the hot part of the light against the dashboard metal when you remove the light. I have lost count of the number of fuses I have lost that way. Oh sure I hear you say, why not disconnect the battery before removing the light? Well, yes, of course.

But, you can do something else. Slip a bit of heat shrink tubing over the flat metal inside the light. Shrink it up and your good to go. Here is a pic (I have a LED festoon replacement light in there). The light green is the heat shrink over the metal strip.

Vanagon – syncro front outer cv joint protection plate

Posted by albell in syncro, vanagon, vanagon mods on February 16, 2013

The story goes that VW introduced these protectors in 1990 for 14″ syncros with the rough road package, and on all 16″ syncros. Here is the English language bulletin.

I wanted some. I worry about logging road debris catching on the front outer cv boot, and that boot is a pain to replace. You can buy them, one good source is Burley Motorsports, but seeing as there are plans for them on the internetubes I thought I’s have a go at making a set.

Here are the pdf’s of the plans I used: CV_protectors_bracket, CV_protectors_Rubber. I scrounged all of the material used, so my version differs slightly from the plans. First up are the metal parts. I had some scrap 14 gage stainless which is not quite as thick as speccified ( 1.6 mm vs 2.0 mm), and I glued a print-out of the plans to the metal and cut to shape.

I bent the parts in a vise (that accounts for the less than crisp bends), then I made a hack-job of the tig welding. I need new glasses, well that is my current excuse for my poor welding.

Next was the hunt for rubber. You’d think it would be easy to find some 1/4″ thick, fabric reinforced conveyor belting, wouldn’t you? I spent an hour looking then I used some 1/4″ rubber sheeting that my neighbour had. It is not the best stuff, it is like thin horse stall matting. You know, crumbled tires pressed together. I can always replace the rubber when I find the belting. Ok, enough mumbling, I cut the rubber and I cut some 1/8″ 6061 aluminum for the backing strip. I used 1/4″ – 20 ss carriage bolts (the square part of the bolt shank will dig into a 5/16″ hole drilled in the backing plate) and nylock nuts to hold all the parts together. Well all but one, I ran out of nylocks and had to use a split washer and plain nut.

Okee-dokee, out to the van and installation. It is a bit of a pain, you have to remove the brake calipers and rotor to get to the backing plate. The same old but important safety warnings apply – van securely supported etc.

Two phillips headed screws holds the splash to the steering upright (or bearing housing, as VW calls it). They were fekkin tight, I doubt they had ever been removed. I had to use an impact driver, but even so I still managed to bugger up the screw heads a tad. I have said this before about my van, despite the ugly areas of body rust I have, all the fastenings (despite how tight they have been) are not rusted in.

Once the splash plate is off the cv protector goes on and the splash plate reattached.

Another view.

Brake rotor back on and the splash plate is now closer to the brake rotor by an amount equal to the thickness of the protection plate, but they do not touch.

The other side went a lot quicker.

And with the van down on the ground.

I got more satisfaction from this little mod than seems normal. I don’t know why this should be. Perhaps because I do worry about catching a branch up there when I’m on logging roads. Or maybe it is because the project went without any real screw ups.

Addendum/clarifications:

Vanagon – Spillbuster cup/glass holder

Posted by albell in vanagon, vanagon mods on February 10, 2013

Good friend Stephen gave me this for a Xmas present and I got around to installing it. Made in Germany of all places, I didn’t think the Germans encouraged drinking and driving.

I didn’t have the guts to try it with a liquid that would be a pain to clean up, so water it was, in a short trip around the farm.

Vanagon – home made muffler installed

Posted by albell in syncro, vanagon, vanagon mods on February 4, 2013

Finally got the muffler installed. Some pics of components are in this post. Since then I made some rough mounting brackets, copy of the stock brackets, but made from aluminum (3/8″ plate) with some 1/2″ studs welded onto the sides (for T-bolt clamps). I didn’t take any pics of the brackets, perhaps I forgot on purpose as my TIG welds were overheated and sloppy (I’m learning, slowly).

Here are the brackets before final shaping, mounted to a spare engine mount.

I copied the stock mounting brackets bolt holes and approximately the curves but adjusted to fit the 6″ diameter muffler. I also copied the relief curve on the bottom side of the brackets, allowance for the transverse connector exhaust pipe. A 90 degree SS elbow and a home made tail pipe was TIG welded on.

Install was pretty easy, brackets bolted right up to the engine carrier, ok, I admit, I didn’t get the muffler quite level. Once installed I realized I could have made thing a little differently to tuck the muffler up a bit higher. But all in all I’m pleased with how it hangs.

You can make out how the T-bolt clamps hang around the welded studs on the bracket. You might also make out the section of SS flex on the transverse exhaust pipe – a quick and dirty repair after cracking that pipe on a logging road trip.

And I made a little video to give you an idea of the sound. It is not as quiet as a stock muffler, but neither is it loud. Does have a throaty note.

I’ve always wanted (for some obscure reason) to make a muffler. And now I have, and by gum it worked. It’s the little things that get me through the day 🙂

Vanagon – Syncro propshaft angle measurements… again

Posted by albell in syncro, syncro specific repairs, vanagon on January 13, 2013

Warning: what follows is a very long-winded and tedious description of my further exploration of propshaft U-joint angles. Experienced and knowledgable readers, please, cut me some slack and refrain from face palming at my antics.

Being quite adept at re-inventing the wheel, I’m now re-inventing measuring propshaft angles. If you are a regular reader of this blog, and man it feels good to write that (evidence of my amusement with small things), you know I have spent some time exploring the flange angles of the transmission and front differential (my previous attempts, one, two, three.). I came cold to this subject, never having to deal with anything like this before, and Bentley has nothing to say about the matter. So perhaps I could be forgiven for my naive approach to the matter. Perhaps, but really no, I should have cut through the crap right away.

A little background

The transmission is connected to the front differential via a propshaft. On each end of the propshaft are U-joints (single cardan joints) that allow a little bit of misalignment between and movement of the transmission and the front differential. Now the problem with U-joints is that they do not transfer the rotational motion of the propshaft perfectly smoothly, ie. without pulsation, especially when the U-joint angles are greater than 3 or 4 degrees and also if the angles differ from each other more than 1 degree (more on those angles later). Most of you know this, and also about the correct phasing of the the U-joints on each end of the shaft, but I do recommend having a look at this document from Spicer that explains all:

Spicer info on driveshaft install, angles, vibrations, etc. (pdf).

And this Spicer document on measuring angles succinctly describes using Spicer’s angle finder doodad.

Spicer info on measuring angles

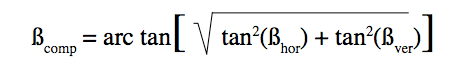

One subject not really covered well in that document is compound angles. That is when there is mis-alignment is in 2 planes, ie horizontal and vertical. I’ll go into that at the end of this post.

Over time I became dissatisfied with my last attempt at measuring flange angles with my laser tool. Don’t get me wrong, I think it is a pretty neat way of measuring the flange angles and it measures both in vertical and horizontal planes. But you need to have the propshaft removed.

After some email exchanges with J. Slider, I reconsidered the protractor/angle finder method of measuring flange angles. I wasn’t very happy with the results I got when I tried this method a while back. I was unable to get consistent results measuring the flange angles with my propshaft removed. It came down to getting the electronic angle finder positioned correctly on the transmission and front differential flanges. But Jon’s argument for the angle finder method convinced me to try again.

I was sidetracked by an idea of a false propshaft jig thing. I reasoned that if I could make a jig that mimicked the propshaft but was constructed so that flange angles could be more easily measured it would be a good thing. I even thought of making a false propshaft with fixed, *ideal* flange angles that I could use to adjust the transmission and front diff. mounts. I still think this would be a worthwhile tool to make for those folk who install propshafts in vanagons.

– This flurry of innovative thinking (ha!) coincided with me removing my propshaft and having it checked for balance by Royce at Island Torque Converter & Driveshaft. Royce is THE guy to take your propshaft to for repair/balancing. He does good work, prices are very reasonable, and he is willing to work with you in solving driveline issues. Local (Vancouver Island) phone # is 250 388 4248 –

Royce and I talked about the syncro propshaft and about making a shaft with Rzeppa type CV joints. That discussion is another story but when I was Googling around with the idea of Rzeppa joints on shaft I came across a document describing the install of a marine, Rzeppa jointed, short prop shaft. In that document (you can see it here) the use of jigs that I described above is detailed. Foiled again. Is it always to be thus? Are all my ideas “a day late and a dollar short”?

I took my propshaft to Royce around the 15th of December and got it back the next day. But with one thing and another I did not get the shaft re-installed in the van until the 9th of January. During that time, when I was not working, eating, drinking, Xmas shopping, sleeping, putting up then taking down Xmas trees, etc, etc, I was mulling over the propshaft jig idea.

Too much mulling, not enough action. So I ended up going back to the protractor/angle finder on the installed propshaft method. You’ve seen this before, and it is described in the Spicer document, I just added a very minor twist.

Home-made tool

I mentioned at the beginning how I was never happy with the measuring propshaft angles with the angle finder because I could not get a good surface to place the gauge on. So I decided to do what others have done and use the ends of the U-joint bearing cup as the reference surface. That meant making a little tool.

A bit of scrap steel from some failed project.

Turned it down and machined a recess in one end to accept a rare earth magnet.

Fits in fine, held in firmly by magnetism and Locktite.

The magnet face is recessed from the rim of the tool by a gnat’s crotchet.

Here is my other propshaft, to be used for trial fitting. Big note here, ideally the circlip should be removed so that the tool can lie directly on bearing cup. But I reasoned that these circlips would be lying parallel to the bearing cups. Any dirt or damage to the circlips would screw things up.

Tool on the joint.

Angle finder on tool, held by magnets on side of angle finder. It looks like the angle finder is resting on flange, but it is not.

Angle finder on end of tool. I was not sure at this time which way would be better.

A bit of channel to provide a base to measure the propshaft angle.

Trying out the tool

Ok then, out to the van. First I had to install the re-balanced shaft (not the red one pictured above). I jacked up one side of van and supported on blocks. Wheels off the ground.

Small aside, I finally replaced the 1/2″ bolt used to hold the jack adapter onto the jack with a gated pin thing.

After the propshaft was installed (please note, I do insist on loosening the 3 bolts that go through the rubber mounts on the front diff. when I am installing/removing the shaft) I took the van off the blocks, released the parking brake and chocks, then crawled under to have a go at measuring angles. First I moved the van back and forth so that a bearing cup on the U-joint yoke that is attached to the flange was pointing directly down. I gave it a bit of a scrub then attached the tool.

See how the angle finder is a little askew on the shaft of the tool? This affects the angle measurement. It was hard to get the angle finder aligned true to the shaft when I was scrooched up under the van. Would have been much easier if the van was on a lift. But I persisted, went on to measure the propshaft angle.

And see how I do not have the angle finder aligned along the channel? It is askew too, and this affect the readinghh. And then on to the front diff. end of shaft.

Repeated the procedure a few times.

A bit better alignment on channel.

Again on the front.

And on the rear.

But I was not happy with the procedure, I was not sure of confident of the accuracy of the readings.

V-block modification and engine carrier adjustment

I tried a nice little Starrett V-block on the tool. I thought it might help me to keep the angle finder aligned along the long axis of the tool.

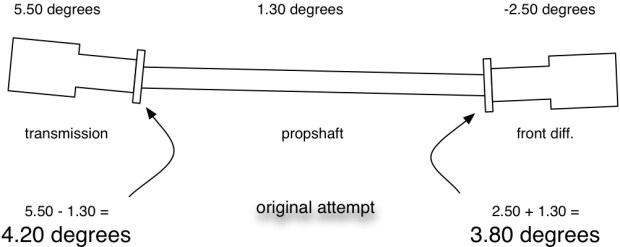

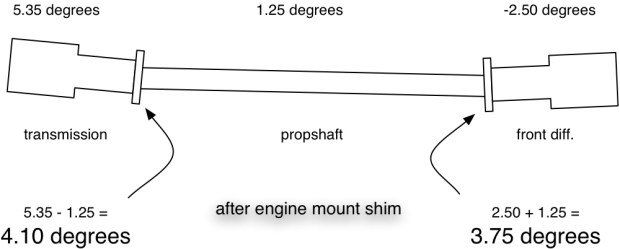

I was running out of afternoon and I wanted to try something more. I knew from previous measuring that the transmission flange pointed down more than the front diff flange. I wanted to reduce that angle, but I also new that there really is no easy way to do that. The transmission mounts towards the front of the transmission are really awkward to get at and fiddle with (especially when you don’t have a lift), so that leaves the engine mounts at the rear. But the arrangement/relative placements of the mounts means that it takes a fair bit of movement at the engine mount to effect a little movement at the transmission flange. Perhaps these data from R. Jones illustrates this (front diff. data included).

“4) I measured the distance between the flanges and the

mounting points, tranny and front diff, and worked the ratios.

Using washers, here’s what one can do:

a) raise front mount, front diff, lower flange.

1 unit raising gets 0.83 units lowering the flange.

b) raise rear mounts, front diff, raise flange.

1 unit raising gets 1.2 units at the flange.

This is the wrong way however.

c) lower tranny at front mounts, lowering flange.

1 unit at mount gets 1.25 units at flange.

Again, this is the wrong direction.

d) lower engine at carrier attachment to frame,

raise flange. 1 unit at engine gets 0.25 units

at flange. Hardly worth it.”

I wanted to try “d”. So I supported the engine carrier (“moustache bar”) with a jack and removed the 2 bolts, each side, that hold the bar to the van frame. I had no time to record flange angles vs. amount of lowering of rear carrier, and I decided to try 5/16″ as the distance lowered. Handy number, I had some 5/16″ aluminum plate scrap on hand. On the top side of the flange on the van body that the carrier mounts to there is a steel backing plate. I used that plate to lay out the bolts holes in the aluminum spacer.

Holes drilled.

And spacer inserted. I used longer bolts. Damn mudflap mounting strut interfered.

Maybe you can tell, the light was fading fast. I got back under and measured angles, using the V-block innovation.

Transmission flange angle.

Front diff. flange angle.

By now it was dark and I was cold. I left things as they as far as I got to: rear engine mount dropped by 5/16″.

It now occurs to me that I have not mentioned another little thing I did (a year ago) to resolve flange angle difference – I removed the topmost metal washers of the two rearmost mounts of the front diff. This did drop the flange of the front diff. a bit – I reasoned back then, that if I could not reduce the flange angle of the transmission the I would increase the flange angle of the front diff. I hoped that matching the flange angles did more to reduce vibrations than trying to get both flange angles below 4 degrees. I’ll clear this up at the end, I know this story is getting very muddy right now.

Road test