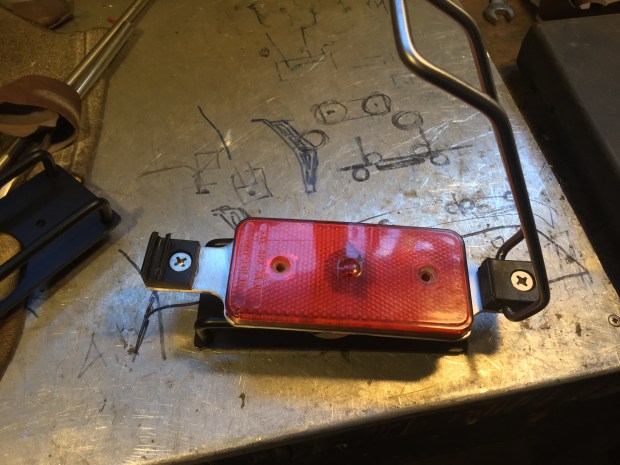

Vanagon – rear side marker light guards

Posted by albell in vanagon, vanagon mods on July 23, 2015

i made a few prototypes, aluminum with quick spray bomb paint. What do you think, silly, sensible, or none of the above?

Update, in a way.

Still fooling with the idea. Made this version to see how a swing away guard would work. The proportions are a bit screwy but I like it enough to to try again.

Vanagon – front bumper build pretty well done

Posted by albell in syncro, vanagon, vanagon mods on July 22, 2015

Beauty and the beast

Posted by albell in Uncategorized on July 22, 2015

Doing some errands and saw this beauty parked at Owen’s garage in Sidney. I had no room to get proper shots, but oh my, isn’t it a lovely thing? Sex on wheels. It’s in my dream garage beside my DS21, 246 Dino, and of course, the syncro 🙂

Later that afternoon I came up behind another one close to my home.

Oh, forgot about another fantasy garage member, this Unimog with the hydraulic firewood splitter up front.

Vanagon – hatch mounted spare tire carrier

Posted by albell in syncro, vanagon, vanagon mods on July 12, 2015

Last spring I finally gave up on my swing away tire carrier project. I couldn’t get it stiff enough for my liking. I’ll post something about that fandango and my new front bumper later. The stock location for the spare was taken over by the big assed battery so I have been using a paulchen rack to carry my spare. I really didn’t like that and last week I made a quick and dirty aluminum ladder type rack to carry the spare. I’m going to give it a bit of testing before clean up and painting, then I will post more on construction details etc.

Trip – Cor, what a scorcher!

Headed out Saturday morning with thoughts of the high spot campsite to catch a breeze and maybe see the Fourth of July fireworks over on Neah Bay. It has been an incredibly dry and hot summer here and the forecast was for mid 30C in the area we were heading to.

Started looking for fireworks early

It was hot and for some reason there were a lot of horseflies and deer flies around. I have to get one of the those electric fly swatters. Nearby pond was so nice, warm, peat infused water. Left you feeling very clean and refreshed. We were back and forth to the lake for a dip a few times.

Still looking for fireworks. Well no, actually we could smell smoke when we arrived, we were wondering where the fire was.

There was, and I think still is, a complete fire and BBQ ban in the back country, so we had pre cooked the food for supper. Grilled meat, grilled and marinated porcini mushrooms, a simple salad, all on a store bought tortilla.

After dinner walk and then back for the fireworks. Yeah, you probably are expecting pictures of the fireworks, but Neah Bay is 20+km from where we were and while we could see them, and believe it or not we could hear them, I couldn’t get a picture.

So I put up some battery powered Xmas lights for a small attempt at acknowledging the southern neighbour’s celebration.

In the middle of the night we noticed the moon was hazy, was it fog or smoke?

Next morning about 6:30 am, eastern sky was reddish.

The smoke haze was moving in form the east.

At times like this, toast is the answer.

We packed up and decided to go exploring. The smoke haze changed the light in a strange way. Some things took on a sepia tone, but the greenery really popped out. Explored along Braden Creek, Loup Creek, got tuned back at the gate on the road near the abandoned Gordon River logging camp, doubled back to Port Renfrew and stopped at the Gordon River a few km upstream of the marina. The point and shoot camera really exaggerated the sepia tone. The iPad Air II not so much.

Braden Creek

And the very low Gordon River

Canon PowerShot camera really made a meal of the tinted light.

On the way home we stopped at “Shirley Delicious” coffee shop in… Shirley. Good stuff. The new wheel and tire combo worked outs great. The tires have a much, much smoother and less jarring ride than the old ones. Traction was better although on some stretches of road it is like driving on ball bearings. I didn’t notice the slight gearing handicap with the larger (5 or so percent?) diameter tires on the rough roads, but did notice it a little on some steep paved grades.

Oh, and once home we found out where the smoke was coming from. Most of it was from Pemberton over on the mainland. Some might have been from the fire at Sproat Lake near Port Alberni here on the island. An inversion layer in the atmosphere kept the smoke contained. I found this, and I admit it looks a bit dubious, satellite pic taken yesterday, Sunday the fifth.

ATA – something’s missing

Posted by albell in aircraft, around the airport on July 6, 2015

ATA – through the chain link fence

Posted by albell in aircraft, around the airport on July 3, 2015

It has been a while since I posted an aviation pic, but I had occasion to drive past the Viking Air building and took their snap through the chain link fence. Boy, sure looks like mid August rather than the beginning of July.

1934 Bentley

Posted by albell in other cars on July 3, 2015

Vanagon – inside the fuse panel

Pretty cool eh?

Source: http://www.vwt3.at/index.php/topic/30428-sicherungskasten-einblicke/

Vanagon – some notes on new wheel install

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on June 26, 2015

i bought the Mercedes alloy wheels last year. They weren’t my first choice, I wasn’t really sold on the flat face look. But the price was right ($100 for 4) and I thought the offset of 25 might work out for me. The ideal offset would have been 30mm, but folks have successfully used ( without wheel spacers) wheels with offset of 37mm on the syncro. Mind you I think those wheels were narrower than 7″.

The whole subject of wheel choice can be confusing. Chris at T3 Technique has good information (link) and there is a very lengthy Samba thread on the topic.

With the alloys having an offset of 25mm I wasn’t concerned about clearance issues with suspension components but I was a little nervous about how much space there would be between the sliding door and the passenger side rear tire. As it turned out there is a good 3/8″ – 1/2″ space between tire and door.

Some time after I bought the alloys, good friend Simon bought a set of Mercedes 15″ steel wheels. 6.5″ wide, offset of 37mm. He offered them to me, we thought that maybe the black steel wheel look would work on my van. If they did both of us would use one of the alloys as a spare, if not then the steelies would be out spare. Simon needs a better rin for his spare.

I had one of each type mounted with tire and compared them on the van. The alloys won. The clearance between the steel wheel and both the front and rear suspension components was tighter than the alloy.

As the alloy wheels have a thicker cross section where the wheel studs locate I had to get longer studs. Well on the rear wheels anyway. The studs are a tad longer on the front wheels so I left them stock. I measured and determined I had 8.75 turns on the lug nut on the stud as it tightens up to the wheel. The thread size is M14X1.5 so that gives 13.13mm of engagement which I think is sufficient . Replacing the front studs on the syncro is a pain. Note that various alloy wheels differ in thickness in this area, some are quite thick.

I got the longer studs from Chris at T3 Technique, hands down the best source for wheel hardware. I had a spare set of rear hubs so I had the studs pressed in, sitting around waiting until I got off my duff.

Also, the lug nut seats on the Mercedes alloys were the small ball type, the stock steel wheels on the Vanagon use large ball seats. So I had to buy some new lug nuts and yes I got them from T3 Technique. Here is a pic comparing the stock Vanagon lug nut to the lug stud that came with the alloy wheels.

And one more thing to do. The Mercedes alloys are drilled for 12mm studs. The Vanagon uses 14mm studs. I enlarged the holes with a 37/64″ drill.

I had a bit of fun getting the hubs off the van. I’ve done this job a few times but this time the big 46mm axle nuts were very, very reluctant to come off. What I normall use is a 1 13/16 socket, 3/4″ drive but for the life of me I couldn’t find the 3/4″ extension and T bar for the socket. So I thought I’d be clever and modify the 46mm slugging wrench I had. Btw, I have a hard time using the slugging wrench in the way it is supposed to be used. I find it hard to get a good swing at it with the heavy hammer without hitting the wheel.

I welded a bit of 7/8 hot rolled steel to the wrench, and that spud fit into the 5′ steel tube I use as my might extension. Well, the hot rolled bent immediately. Ok, I cut it off and welded on a found section of bar stock. I had the notion that this particular bar stock was perhaps a stronger steel.

Why the heck did I weld it on with the hole at that end? I can’t explain this bozo move.

Well that shifted the rig hand side axle nut, but it bent a little in the process.

But Mr Wrench (and my weld at the end) was not up to going after the other side.

I nipped over to a friend’s shop and he easily loosened the nut with his Milwaukee battery powered impact gun ( has 1100 ft lbs of torque).

Mr Wrench was still strong enough to re-torque the nut to the 365 ft lbs the bugger needs. I added a bit more weld in the hope that I can use him again sometime, in his new cranked conformation.

I’ve yet to get some good shots of how the wheels and tires look on the van. In the meantime here are some quick snaps of my van and good friend Simon’s van. Simon has South African Carat (?) alloys and Nokian WRC 205/70-15.

Vanagon – tire and wheel comparison

I just installed, at last, some new wheels and tires. I dithered for so long and ended up with a compromise. The wheels are Mercedes alloys,15″ x 7″, ET of 25. The tires are Yokohama Geolander ATS 215/70-15.

The offset is a bit lower than perfect, the wheels stick out a little more but that gives a tad more clearance on the suspension side and the sliding door clears tire by a good 3/8″.

Simon left his van with me while he is on a trip to an un-namable place so I had a chance to do a visual comparison” his wheels are 15″, ET 30, and I think 6.5″ wide, South African carats. The tires are nokian WRC, 205/70-15.

I have only riven a short distance on my new tires but I lie, what I feel so far. Smoother over bumps, little tire noise. They change the feel of the van in a very good way.

Here is quick vid of the two vans, Simon’s van is the high top.

Trip – Much of the same

Another weekend trip to favourite places. A little different this time as there was little fog. I hope the residents of Neah Bay across the straits took the opportunity to hang laundry.

Obligatory clear cut shots.

And one of our favourite creeks.

Saw lots of shipping with the lack of fog. Cruise ships, oil tankers, and container ships. a few of this kind went past. I like how the containers are stacked in a subtle wedge shape.

Came across a doe and new born fawn. Fawn was very shaky and wouldn’t get out of the way.

“and my axe”

Mmm, chicken

ok, another cheesy vid, this time the creek

Trip – same old same old, but finally the first trip of the year

For various reasons we haven’t managed to get out using the van for its intended purpose until this last weekend. It was just an overnighter to familiar places, but still a fun outing.

Driest May on record here this year, and the Thursday and Friday before we left felt like August. It wasn’t quite August out on the west coast, the wind was coolish, but the sun was warm.

The syncro was a champ, hauling us up loose gravel and rock logging spurs, and the newly installed big assed auxilliary battery didn’t even blink about the amount of electricity we used. The battery truly is way bigger than we will ever need, its both daft and kinda fun to have it.

And yes, we camped beside clearcuts 🙂

On our way, we realized we had left the Thai themed marinated chicken thighs back at home, so we picked up some meat strips in Sooke.

Where’s Waldo?

Vanagon – big battery installed

Posted by albell in vanagon, vanagon mods on May 24, 2015

It took longer than making a baby but I finally have my big battery installed. I got this Northstar 200 AHr battery some time ago, I think I mentioned it in this blog post. The size and shape of the battery made it seem like it would fit easily under the rear seat but it just doesn’t ( without taking up more space than it needs, if that makes sense). I toyed with the idea, and went as far as making brackets, of mounting it up under the van between the door sill and frame rail but no, that didn’t look right. So I settled upon the admittedly dubious spot of where the spare tire sits. A couple of problems with this placement. Number one is that I now have to find a spot for the spare tire. Ah but what about my much talked about swing away spare tire carrier? More on that at the end of the post. The other dubious characteristic of this battery location is that it places 128 lbs forward of the front wheels. I’m a little worried that it might make a difference in how the van negotiates dips and ditches in logging roads. Skipping a head a bit, I have had the battery installed for a week and I really don’t notice any driving different on paved roads. I made a carrier for the battery quite a while back, crikey, it was a year ago, since then I welded in some locating brackets that the battery fits into, and some tabs on the side tubes for supporting brackets. The brackets are made from 1X1/8″ stainless and I bent them to fit to the van frame rails. They are secured to the frame rails by 5/16″ stainless bolts that I will someday change to 8 mm. The bracket to the tab connection is done with 1/4-20 bolts and instead of nuts I used stainless ring nuts. The rings are to secure nylon straps that cross the battery and hold it very securely to the tray. Ok, some pics of it installed. First pic taken from driver’s side, one stainless bracket not fastened. Gives you the general idea of how the battery lies.

And on the passenger side. You can probably make out the red nylon hold down straps going up over the battery.

I had thought of making aluminum side splash plates but I was dissuaded by the changing angles and company curves needed so I used some scavenged treadmill material. I installed 1/4-20 riv nuts in the existing holes in the van frame and bolted the treadmill material.

It’s not great but it’s not bad. It’s just there to reduce water splashing on the battery. Not shown in the pic are tubes leading from the battery vent up over the battery and on up to behind the front grill. When I did that I was thinking I was clever, I thought that leading the vents up high would prevent water getting into the battery if I happened to go through a deep puddle. But I found out later that the battery vents have a valve in them to prevent water ingress. A note on the wiring. I ran a short length of 4 gauge wire from the negative terminal back to the bolt holding on the transverse member supporting the front differential. On the positive terminal a short length of 4 gauge comes off the terminal and up into a black box (attached by Velcro) on top of the battery. In that box is a Blue Seas Maxi Fuse block, with a 70 A fuse.

Update: in the comments Marius wondered about battery cold weather performance. Here is a graph I found in one of Northstar’s documents .

Then out of the box and through some plastic sheathing and a sealed bulkhead fitting into the battery compartment behind/under the driver’s seat. Then it continues on to connect with my Blue Seas ACR. I’ll write more on that when I tidy up the wiring, I’m going to change the auxiliary power distribution layout there. I was surprised and pleased to discover that when all is bolted up tight the stainless straps from the tray to the frame seem to support the entire weight of the battery. The bolts at the rear, where the tray hinges on, have no weight on them. So that pretty well sums up the installs the battery. As mentioned I will post more on the auxiliary power distribution set up when I finally fix the positions of the various components. So… The spare tire, where does it go? It’s time for a confession, I couldn’t get my swing away tire carrier to work the way I wanted to. I’m not going to explain all the things I tried, and I did try a lot of things. But I could not get happy with the rigidity of the set up. The tire vibrated in the carrier when I smacked it with my hand. It bugged me no end. I finally lost my patience and removed it, cut out the hinge from the bumper and welded the bumper back together and painted it. I’m going to make a hatch mounted tire carrier, don’t laugh… Yet. In the meantime I’ve pulled my old Paulchen rack out and I have the tire bolted on that.

Then out of the box and through some plastic sheathing and a sealed bulkhead fitting into the battery compartment behind/under the driver’s seat. Then it continues on to connect with my Blue Seas ACR. I’ll write more on that when I tidy up the wiring, I’m going to change the auxiliary power distribution layout there. I was surprised and pleased to discover that when all is bolted up tight the stainless straps from the tray to the frame seem to support the entire weight of the battery. The bolts at the rear, where the tray hinges on, have no weight on them. So that pretty well sums up the installs the battery. As mentioned I will post more on the auxiliary power distribution set up when I finally fix the positions of the various components. So… The spare tire, where does it go? It’s time for a confession, I couldn’t get my swing away tire carrier to work the way I wanted to. I’m not going to explain all the things I tried, and I did try a lot of things. But I could not get happy with the rigidity of the set up. The tire vibrated in the carrier when I smacked it with my hand. It bugged me no end. I finally lost my patience and removed it, cut out the hinge from the bumper and welded the bumper back together and painted it. I’m going to make a hatch mounted tire carrier, don’t laugh… Yet. In the meantime I’ve pulled my old Paulchen rack out and I have the tire bolted on that.

And the bumper… well its ok, but I’m not ecstatic about how far the end caps stick out, oh well maybe I can say it provides better side protection and its Mk I. And i still have to paint the tow loops and the receiver hitch.

ATA – Early summer Beaver report

Posted by albell in aircraft, around the airport on May 20, 2015

North Island correspondent Phil Z. sent some pics of Campbell River Beavers with focus on cabin windows.

Uodate: Phil writes that this is a turbo V8 engine in Beaver pictured above. More info here

http://www.sealandaviation.com/blog-entry/first-trace-beaver-flight-floats

Vanagon – kinda crazy sway bar mod to help install homemade drop links

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on April 25, 2015

This value of this modification to the sway bar is debatable. But hey, don’t let fear and good judgement hold you back from having a bit of fun. And god knows I’m not going to sit here and tell you this is an original idea, I’m old enough to know that someone somewhere has done this before.

I didn’t look forward to installing the sway bar drop links with Whiteline polyU bushing. It can be a bit of a struggle getting the drop link onto the sway bar. Mind you, Chris at T3 Techiniques makes it look easy in his video. By the way, T3 Technique is a place to buy polyurethane bushings and other suspension parts.

http://www.youtube.com/watch?v=7oXY68F8Uwo

I had thought about the notion of cutting the knob end off the sway bar then drill and tap a hole so a thick washer could be attached to replace the knob. But I didn’t like that idea for a few reasons.

So what I did do was this, I welded a 3/8″ stainless steel bolt to the end of the sway bar. Well I should say sploodge welded the bolt on, not pretty.

So what eh? Well now I made a bullet shaped tool, tapped for the 3/8″ bolt on the blunt end and tapped for 1/2 NC on the pointy end.

Some tubular spacers, lube, and a nut and the bushing ( already fully seated in the drop link by squeezing the two together in a vise) and hey presto, the bushing and link can be easily pushed on to the sway bar. Hey don’t rely on this pic for correct orientation of the sway bar bend to the sway bar, I was just doing a test run and didn’t take care. I did get it right in the final assembly… I think 🙂

i made a Delrin cap to fit over the exposed bolt. Tidies things up and may help to prevent the drop link coming off the end of the sway bar. This has happend with the softer urethane Powerflex bushings, maybe not as likely with the harder Whiteline bushings I have used, but hey, it’s another justification for this mod.

And of course I scraped the heck out of the paint on the sway bar installing it on the van.

I guess I should show hey finished drop links. I had machined them a while back, 3/4″ (19 mm) stainless rod and heavy walled ( sorry I forget the wall thickness) tubing which had ID of 1 1/2″ (38mm) very close to to the stock link. Threaded the end M12X1.5, and a section approximately 17mm in diameter where it passes through the drop link bushings. No spacer in this set up, we’ll see how that works out, but is not an original idea.

I guess I should show hey finished drop links. I had machined them a while back, 3/4″ (19 mm) stainless rod and heavy walled ( sorry I forget the wall thickness) tubing which had ID of 1 1/2″ (38mm) very close to to the stock link. Threaded the end M12X1.5, and a section approximately 17mm in diameter where it passes through the drop link bushings. No spacer in this set up, we’ll see how that works out, but is not an original idea.

I bent them on a friend’s press using a quickly made set up that does leave some dimples in the bar. I think I took about 8 tons of force to bend them. I was shooting for 4 degree bend, but I went a degree or so more. I don’t think that will be a problem.

I cut them to length and ground a chisel point on the end. One root pass, then two straddling passes of weld, then I washed over with the torch. I got a bit of under cut on the rod, I could have done better but it will be strong enough. Notice the pattern on the ring portion, patented “Chattr-Mastr” finish on the bevel.

I used the cup washers I made a while back, but welded on a smaller diameter flat washer to the should of the drop link as I was worried that the enlarged hole of the cup washer would get pressed over the shoulder under hard use in the van. I think you might spot that washer in the pic of the sway bar install. I’m happy with these drop links, maybe not in the same league as Burley Motorsport’s, but ok for an amateur.

And another thing, with the bolt welded to the bar it is possible to make some little adapter so one could use a puller to remove the drop link from the bar easily. Ok, that’s a pretty weak advantage of this modification but I’m trying to find other reasons to account for the time and effort.

Vanagon – frustrating sidetrack

Posted by albell in vanagon, vanagon mods on April 19, 2015

Had a really frustrating week, seemed as though everything I touched went sideways. Most annoying was trying to eliminate vibrations in my swing away tire carrier. The latch pulls the swing away tight to the bumper assembly and I am pleased with how that finally worked out, but I don’t like the small amplitude vibration I get on the holder when the tire is attached. I think I am going to weld on a stiffening gusset to the upright and see if that will stiffen things up.

I bought a cheap rod bender from Princess Auto, this one here. It was on sale for 79 bucks. It works ok for what it is, and I thought instead of just bending random shapes while I try it out I would actually make something “useful”.

Well, I tried making a tail light protector and I soon realized that you REALLY NEED TO MAKE A JIG!

I’m showing you the result as a warning, think things out before you start merrily bending stock 🙂

The the tricky part was locating the little stand-offs accurately on the screw holes in the tail light. It’s obvious that the tail light is thicker at the top, but it also has subtle curves laterally and I was trying to match those curves and that made placing the little hollow studs for the mounting screws maddeningly difficult. You can see the nasty welds at those studs, result of tacking, checking, cutting, tacking, checking, cutting…

You really do need a jig.

And I think the guard would look a whole lot better if the vertical cross wires were not welded on top of the horizontal wire but welded to the middle of the section. I’m not going to try another until I make a jig, but even assuming I pop one off without pulling out my hair, these would be fussy and expensive Vanagon jewellery.

Vanagon – Simon feels small

Friend Simon traveling this last week, parked beside white van at Hood River Oregon.

Admin – sorry about blog glitches

The picture scaling issues and inability to to get full sized image when image clicked are my fault. I’m working on fixing it.

Vanagon – attempts at making cup washers

Posted by albell in vanagon, vanagon mods on April 6, 2015

Not quite an unqualified success, but not a complete failure, I’ll settle for that. One of my sway bar drop links broke again and instead of the kind of repair I did previously , I decided to make new ones from stainless and beefier stock. I’ll detail that build when I have them welded up and bent. But I needed new cup washers and rather than buy them ( aren’t they around 13 bucks each?) I thought I’d have a go at making some from 2″ stainless washers. Here are my results.

First I tried pressing a ball bearing into the washer with a socket as a back up. You see on this test washer that it doesn’t make a good profile.

And on the 2″ washer.

So then I tried a different approach. Pretty self explanatory.

Useda friend’s press,applied between 10 and 15 tons of pressure. I also tried both ends of the male die, but the result wasn’t that great.

So I tried again. A quickly made female die with a rough profile of the shape I wanted, and a not very close match on the male.

Back to the press and…

Well not great either, but I’m going to stop. I’d didnt do any research on how one should make dies for this purpose, i bet I am missing something quite obvious

The end of my unfinished drop link.

And with polyurethane bushings and the new washers. Hey, note that I have ground a rough radius on the inboard side of the bushings. This helps them fit into the recess on the lower control arm. No’ they aren’t quite that same as the stock washers. The stock washers have a larger un curved area and turn up more quickly at the edges. But I figure when the bushings are compressed when installed, the washers will make enough contact and still allow some lateral movement of the drop link.

Vanagon – rear bumper, swing away tire carrier latch

Posted by albell in vanagon, vanagon mods on April 3, 2015

As I’m now using geological time scale in describing the progress on my rear bumper build, this latest update comes very quickly after the back up light install.

I needed to make a latch that would secure the swing away carrier tightly, but yet be reasonable easy and quick to use. I tried four designs, my designs, conclusively crappy designs. This, my fifth attempt would be my last, next stop would be buying a de staco type draw latch.

I still had the Delrin cone and socket arrangement that was for my first design. The cone and socket does work well to locate the arm to the steel back stop that is welded to the bumper subframe. So I kept that and made a draw latch.

Reinventing the wheel.

But I learned a bit while doing it. It’s interesting how the effective lever arm changes on an offset hole draw mechanism like this. The pivot points, effective distance, changes from about 3/4″ when draw hole ninety degrees from the pivot to zero when draw pivot are inline. This gives great mechanical advantage when closing the latch, and the over centre part helps keep the latch closed.

I occurs to me that describing all this is a bit of a mug’s game. Maybe some of you think that I should have bought a latch and be done with it, a very valid point. Some of you are probably not very interested in some damn latch – just show the finished project, an equally valid point. And some might think I’m boasting about making the darned thing. It’s that last suggestion that bothers me.

You could make the case that writing any kind of blog is a tad egotistical. But believe me, the best thing about writing this kind of blog is finding out that you might have helped or at least nudged someone in the right direction.

Ok, enough blether.

I made the handle from 1″ thick aluminum. Part of some offcuts from the water jet guy. Had a nice curve and I continued the curve ti make the working end. Drilled holes for the pivots, slotted the end for the fixed pIvot ( that attached to a little bracket that was made from some 1/8″ thick stainless, mounted to the carrier with 1/4-20 bolts, helicoil inserts in the carrier).

I turned and milled a bit of stainless to hold the bail ( the moving pivot) and the bail is a bit of 5/16″ stainless rod that I bent into a U shape and threaded the ends.

I used some 1/8″ stainless plate and 1/4″ rod to make the little catch on the backstop that hooks onto the bail.

I was worried that there wouldn’t be enough give in the mechanism, so I stuck in some hard rubber washers under the nuts on the bail. You can see them in the first two pics. I found that there was enough flex in the backstop latch that the washers weren’t needed.

Ok, the handle and fixed pivot.

And mounted on the bumper.

See how I have to use some spacers to match the thIckness of the cone and socket bases to give the upright of the carrier a bigger surface to pull against? I’ll try and make a nicer version of the spacers, maybe one piece.

I have to make a plug for that hole. Also a fair bit of grinding and sanding to be done before painting. But hey, I’m making some headway.

Oh, and I have yet to weld on some sort of tab thing on the end of the handle so I can pin it to that curved tube as a safety or even a lock.

Vanagon – carpaccio flooring

Posted by albell in vanagon mods on March 26, 2015

My old floor, shown here in this post, was really getting a bit beat up. It lasted close to 15 years taking quite a bit of abuse so I can’t complain. When I put that floor in way back when, I had it in mind to face it with cork and I still hope to do a cork floor someday, but I found something at work that tempted me.

The stuff came to us protecting some stainless steel weather bouys. Approximately 3/4″ thick, the material is closed cell foam and quite stiff. I’m thinking its polyethylene, but it sure isn’t soft. It is very tough, the surface seems resistant to catching sharp edges. It also has strands of some sort of fibre embedded, to reduce tearing I guess.

I cut it up into strips and installed between the seat rails.

Pretty bright eh? But most of the time I have some of those interlocking foam pads on the floor.

And all covered by an inexpensive bit of carpet from Canadian Tire.

Here is a close up of a scrap of the foam.

You know, having that bright colour on the floor makes me want to have a brighter coloured throw rug.

St. Paul with sword and Bentley.

Vanagon – the ongoing rear bumper build – back up lights

Posted by albell in vanagon mods on March 25, 2015

It’s getting embarrassing, but I still haven’t finished the job. What is stalling me is a latch to hold the swing away tire carrier very tight against the back stop. I’ve made a few latches but none have combined the two key features of holding it tight and being very easy to use. The rest of the bumper is finished but still unpainted. Recently i added back up lights to it.

For the last year I’ve had the bumper installed and a 4″ halogen aux light bolted to the top for a back up light. I put a 100W H3 bulb in it and yes, it does light things up. A bit obnoxious in parking lots, but really useful out in the bush. But that was just a temporary thing, I now have my real back up lights.

They are a pair of 10W LED units bought from Deal Extreme. Here is the link to the product page. They are pretty nicely made little units. I cut a couple of holes in the bumper, welded on some mounting brackets on the inside and installed them.

First the before shot. Note that in this shot I have the stock incandescent bulb in the right taillight, a new LED bulb in the left taillight.

The aux light covered up, showing the improvement in lighting the LED bulb in stock taillight.

Ok, aux light removed, internal mounted LEDs installed. Daylight pic.

And night shot.

I like them, they work well. I am probably going to wire them to a spare switch I have up front so I can disable them in the city.

Campbell River report

North Island correspondent Phil Z. sent me a few pics over the winter.

Rain and a fairly high tide makes it look like the boats can come right on the parking lot.

Douglas Squirrel catching Phil’s flash.

Trying not to use the word iconic, dammit, too late.

And the turbo prop Beaver.

Oops

Hey Mister, yer missing the Beaver.

Vanagon – 85 Doka

Ive been doing little work on my neighbour’s ’85 Doka recently. It was originally white but he did a quick paint job which I think looks very good. The colour scheme works well. He also lowered it and put on some 18″ wheels.

I pulled the dash and heater box to replace the motor and re-foam the heater box flaps. I don’t think the dash had been removed before but it all went easily, even the heater box bolts that go through the front body wall and are exposed behind the grill. Often those bolts get rusty and are a bear to remove.

The heater core was filthy but no leaks.

As a replacement blower motor I used a Vanagon A/C blower. The housing is identical and it fits in perfectly. The actual motor has, to my eyes at least, an improved end bearing/bushing. not as exposed as the stock motor. I added a little lube and then JB welded a bottle cap to cover. Kinda hillbilly, but it stuck on there well.

The other difference with the A/C motor are the electrical connections, but it is easy enough to splice it in. I know in the pic, the wiring looks a little sloppy.

As expected, the foam on the heater box was pretty well all degraded. For a replacement I used truck canopy foam tape found at local RV store. Its open cell foam with a clear plastic face on one side and adhesive on the other. The important thing, well I think so, with the foam is that it should be very compliant. The flaps have to be able to close with little effort. The plastic face on this particular tape reduced that compliance, but I discovered the face could be peeled off. On some of the flaps its a bit tricky to get the sticky backed foam in place, but you can remove one of the flap sets to make that easier. Oh, forgot to say, the heater box had not been touched before this so I had to cut off the tabs that are plastic welded together along the split seam. This time I used an angle grinder with a 60 grit flap wheel (blending disk) to grind the tabs off. That worked the best of all the methods I’ve tried over the years. There were a few metal clips on the seam, strange that wasn’t the full compliment to use when fitting the blower back together. But I had some in my parts stash.

But you’re not reading this, I hope, for a blow by blow description of the heater box R&R.

Old motor in the right, A/C on the left.

A/C motor, note end bushing.

And the old blower. It is tempting to say the end bushing is more exposed.

And the bottle cap glued on 🙂

Foam tape with the plastic faced peeled off.

Dash back in place. Stereo had unit still out, the PO had done a really poor job of wiring, I had to come back a week later and redo do all of it.

Foggy morning in February

Posted by albell in around the airport on March 24, 2015

ther’s a company near Sidney that builds fairly large industrial mechanisms, pulp mill and coal conveyor parts for example. They ship the parts out on barges that come in on high tide at Patricia Bay. The parts are transported across the peninsula via the airport’ at night of course. One morning a I took this picture, you can see the conveyor heads at the dock. The water is so still.

Pork jowl

I like buying a pork jowl now and again and curing it with some salt, a touch of sugar, and thyme. In the fridge like that for a week or so then tied up and left for maybe a month. Italian name is guanciale.

Some sexy kitchen bondage video, about as interesting as those wood fire videos or Norwegian slow tv.

Vanagon – rear drum brake helpful image

I found this image on the Samba a while back, I think it was posted by Alaric. It’s a very helpful image to have around when you are working on the rear drum brakes. I know I get confused what goes where and in what orientation.