Archive for category syncro

Vanagon – rear wheel bearing redux

Almost exactly a year back I replaced the bearings in right rear wheel, but a couple of days ago I noticed some play in that wheel. I thought more play than there should be (i.e. none to a teensy amount). So I pulled the bearing housing and this time taking the driveshaft and CV joints with it. That meant CV joint to transaxle connection detached. I had a spare assembly, all greased up and ready to go, was from my old ’82 westy and still ok.

Got it installed ok, never really a fun job. Then I had a look at the one year old rebuild. I had the notion that maybe the bearings might be loose in the bearing housings, but no, they had to be driven out with some effort. The outer bearing looked fine, but the inboard bearing looks discoloured.

And it feels slightly rough when spun. So what’s the story? Did I not lube it enough during install? This picture from then looks like I did not put much grease into the bearing, but what you see is the stuff I had smooshed into the bearing, more lube was put on after the bearing was in place.

Maybe I did screw up, wouldn’t be the first time.

Update: looking at the bearing again, I’m not so sure it overheated. It looks more like corrosion on the outside of the outer race. Still puzzling.

Addendum: I cleaned up the CV joints on the axle I removed and one joint is ok, the other is on its way out. I have to admit that I had not serviced the rear CVs since I bought this van a couple of years ago, it really should have been done. The grease was a bit dry on both joints, and one showed signs of impending failure (Ed. jeez, that sounds a bit over dramatic).

Outer race removed.

Expected and acceptable wear.

One of these balls is not like the other ones.

Inner race, would this erosion spread?

You kinda wonder if tri-annual repacking of CV joints is the way to go, or just replace them every seven years or so. It is a bit of a chore getting the axles off, and more of a chore cleaning and repacking. CV joints are about 90 bucks a piece here, I don’t know what is the best strategy.

Simon’s hightop painted

Posted by albell in syncro, vanagon mods on March 17, 2012

Vanagon – VW pop top insulation

Posted by albell in syncro, vanagon, vanagon mods on February 13, 2012

Borrowed from good friend Simon, this genuine accessory is supposed to be installed outside the pop top but with the rain fly on, I thought I’d see if it was able to be installed inside. A little bit of a wrestling match, but it goes in and stands up by itself. Hey, notice I still haven’t installed an upper bunk.

Vanagon – Go-Westy “Wasserstopper” rain fly

Posted by albell in syncro, vanagon, vanagon mods on February 13, 2012

Note: clip fitment issue resolved, see this post

A Xmas gift installed. Over all pretty good but I don’t like the side clips that are supposed to hook on to the rain gutters. They have a too tight curve and don’t grip well. Also, the strap that goes in the front doors and hold the front of the fly down tight to the van is not that great of a method. I’ll try modifying both. However, as is, the clips do attach to the Shady Boy awning box. No way to get them to attach to the gutter with the awning box in the way. Link to Go Westy product page here.

Vanagon – Small Car stainless header failure

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on February 12, 2012

Was installed new about a year ago, in a EJ25 powered syncro. I suppose disappointing would be one way to describe it.

Vanagon – wiper shaft lubrication

Seems like a slim subject for a post, but perhaps some of you don’t know it can be done. The shafts that stick out of the front of the van, and to which the wiper arms are attached, have a plain bearing sleeve. I bet that over time any lubrication in the sleeve is lost and the shaft gets that little bit harder to move.

I have a spare wiper assembly in the barn, so here are some pics of the shaft and housing.

Front view, showing the splined area that the arm meshes with, the threaded end for the wiper arm securing nut, the threaded base that the big nut that holds the housing in place on the sheet metal (the housing is also held to the van by phillips headed screws that you can see at the front edge of dash board near windscreen). You might be able to make out a circlip just above the large threads.

Circlip removed, 2 washers, and a rubber grease seal.

Back, inside view of above, circlip and washers removed and the shaft pushed back. This exposed shaft is what need lubed.

Make sense? Ok, out to the van. First pry off the plastic cap at the base of the wiper arm. See the little slot on wiper arm base where you can insert a screwdriver to twist off the cap?

Cap off, 10 mm nut exposed. Often it is pretty rusty in here.

Remove nut and thin washer, wiggle wiper arm and remove from stud. The splines will look cruddy like this one, no worry, clean the splines out with a pin/needle. It’s these splines which bite into the softer metal of the wiper arm that prevents the wiper arm from slipping, not how tight the 10 mm nut is. So spend some time to clean the splines out.

Pry off the black plastic shroud. Careful, don’t scratch the paint.

That big nut is supposed to be somewhat tight, 69 in. lbs (8 Nm). You can see the golden coloured circlip, remove that (don’t lose it!).

In this pic the circlip and the 2 washers have been removed, and the 10 mm nut put back on the shaft (to give me something to hold on to). The shaft was pushed in and out a little and that made the grease seal pop out.

Bentley says to use molybdenum disulphide grease on the shaft, I used gear oil. If I had the shafts right apart then grease would make sense, but seems to me that oil is better in this situation.

And then it is just a matter of putting it all back together. The circlip might be the hardest part to re-install. The wiper arm nut is tightened to 5 Nm (43 in. lbs). Do not over-tighten, risk of strippage! I place the arm on the shaft and before tightening the nut, I move the arm into proper resting position Then tighten the nut and the assembly draws up without moving out of position. Oh, and another thing, I glob some waterproof grease onto that nut to reduce rusting.

Vanagon – front door check strap

A few months ago my driver’s side door was allowed to swing open hard (van parked on hill, happened on this trip) and the check strap snapped. Got around to fixing it today. I had a spare assembly from my ’82, straightforward swap.

After the door card is removed, you can see the check strap assembly inside the door. The ’86 has a plastic cover over the works, the old ’82 did not.

Cover removed, two phillips head screws holds the mechanism on.

Removed and the broken end on the other side. The remainder of the strap, the part attached to the door jamb and held on with a pin and circlip arrangement was removed when I snapped the strap.

The replacement unit, and the waterproof grease I’ve been using recently for this and that. The stuff really does seem to resist washout better than regular grease (ie on shift linkage)

Installation is simple, no gotchas, here is pin on body end of strap.

Addendum: In the comment Jon asked if the check strap could be adjusted to give more resistance. I can’t see how that could be done, perhaps Jon’s mechanism is broken? Here are more pics of the “resisting elements”, the hard faced rubber bits that pinch the steel strap.

Vanagon – syncro front diff. input seal replacement

Posted by albell in syncro, syncro specific repairs, vanagon on January 13, 2012

Back in October last year, when I had the front diff. out to install a new VC, I noticed that the input seal was leaking. It would have been smart to replace it then, but I couldn’t wait for the seal to be ordered in. Then I procrastinated, put the job off until today. The job is quite straightforward; disconnnect the prop shaft from the front diff., undo the 24 mm nut that holds the drive flange on the input shaft, remove flange, remove seal, replace seal, replace flange, etc.

Addendum: Have a look at this thread on Yahoo Syncro list for discussion on cheaper seal. I didn’t see that thread before I bought the expensive one from dealer.

I’ll be pedantic and list the steps I took:

– chock pass. side wheels and jack and support driver’s side so that left rear wheel is off ground (you could have both wheels that side off the ground, would be easier to rotate propshaft to get at all the propshaft flange bolts)

– loosen the 3 bolts (17 mm) on the rubber mounts on front diff.

– mark the propshaft flange, the front diff. flange, and the front diff so that you can get all the bits back in same orientation.

– remove the 4 nuts and bolts holding propshaft to front diff. flange (13mm, use 2 open end wrenches), and let the propshaft rest on ground, or support with wire.

– rig up some sort of tool to hold the flange as you undo the nut (24 mm), the nut is on there tight (135 ftlb). My elegantly engineered (ha!) flange holding tool required the pass. side propshaft protection rail to be lowered a tad.

– a 2 arm puller to pull the flange off the shaft, came off very easily.

– the exposed seal can be pried out with a strong screwdriver. I was surprised at how secure it was in there. Be careful not to damage the aluminum housing.

– some oil will drip out, have a container in place to catch it

– new seal is lubed then, as the Brits say, offered up to the housing. I used a brake caliper piston to carefully drive the seal home.

– then the flange, and the washer and nut. Again you need to hold the flange as you tighten the nut.

– propshaft back up and secured.

– some gear oil squirted in the fill hole (17 mm socket head plug) just back of the driver’s side inboard cv joint.

– the diff mount bolts left loose for a few miles, then tightened up. Just to allow the front diff to settle in a happy place (a sort of horizontal self alignment).

Addendum: overview of area. 26 = 24 mm nut, 25 = thick washer, 24 = input flange, 23 = seal (22 = circlip and 20 = bearing. Both un-involved with this repair)

Here are some pics:

See the oil splash?

Propshaft removed, the 24 mm nut that holds the input flange on is revealed.

Flange held firm using homemade tool, nut loosened.

Flange off, seal exposed.

Shots of how the brake caliper piston is a good fit to use as seal seating tool.

New seal installed.

Vanagon – syncro viscous coupling anatomy – part 2a

Some more images of the slots on the slotted plates of the VC. Any burr or ridge is not so clear, but perhaps there is one on the worn side of the plate. The series show the same plate, un-worn, then worn side. Clicking on the pics will bring up larger version.

Un-worn side.

Worn side.

Un-worn side.

Worn side.

Vanagon – syncro viscous coupling anatomy – part 2

I took some pics (btw, all the pics can be clicked on to get larger image) of the plates in an attempt to see those “burrs” on the holes or slots that are implicated in the hump or STA (self torque amplification) event. I think having my sketch diagram of how the plates and spacers are arranged would be useful here:

Here is the stack as it comes out of the VC. Note that the circlip and shims are not on the end of the shaft. Also note that the top plate is not held in the stack by the circlip, but rather is pressed against the endplate when installed.

The reverse side of that top plate, obviously worn.

And the slotted plate below.

Now remember, these two top plates are not spaced apart. The next plate however, is spaced from the slotted plate you see by approx. 0.025″. Mis-focused on this pic, but included it to keep the arrangement clear. See the wear on it even though it is spaced from the plate above?

Here, with the above plate beside, slotted plate turned over.

Closer view.

Here are the adjacent surfaces of another pair, same arrangement as the worn pair above, ie has spacer separating them. Note that they are not worn.

Now lets get a better look at the punched holes.

Closer, I’d say there was a raised rim, very subtle.

And a shot of worn plate holes. I think you can see where the rim/burr whatever you want to call it has been worn.

I only had time to get one close up of the slots in the other plate type, no rim evident on this side at least.

Well, this exercise demonstrated, to me at least, that there are burrs on the punched holes. As to the role of these burrs, I will deal with that in part 3.

Vanagon – syncro viscous coupling anatomy – part 1

Posted by albell in syncro, syncro specific repairs, vanagon on November 21, 2011

This post is just to clarify, a little, how the plates inside a viscous coupling (VC) are arranged. My post on replacing a VC shows more pictures of the assembly and the seals.

Maybe a couple of pics of the VC (end plate removed) to set the scene. Note the end shims, and the absence of the circlip (groove for it in shaft is visible) that keeps the plates all together.

Another angle, end shims removed.

There are 24 pairs of plates in the VC. One set are keyed to drive (or be driven by, semantics) the VC housing itself. So these plates have notches around the edge that fit in internal splines on the VC housing. They also are the plates with the circular holes in them. The other set of plates, slightly smaller in diameter, are keyed to drive the central splined shaft. They have slots in them. The propshaft from the transmission is connected to the housing, the pinion of the front differential is connected to the central shaft of the VC. The silicone fluid filling the VC is what mediates the power transfer between the plates. I won’t be going into the silicone fluid in this post.

There are spacers between pairs of plates, and these spacers fit into the hole in the middle of the plate that is keyed to the housing. The spacer is (all measurements are approximate) 0.065″ thick. The plates themselves are 0.040″ thick. So with the spacer partially lying in the hole of one plate, it only projects about 0.025″. That means the plate pairs are separated from each other by 0.025″. I think it is time for a simple diagram.

Does that diagram make sense to you? You can make out the spaces between the plate pairs in this picture of the entire stack o’ plates out of the housing but still on the shaft.

Oops, looks like I left the last plate in the housing. Also the aluminium ring I am using to support the plates is causing the plates at the end to be pushed upwards. Of course when in the housing they are all aligned. Here is a closer view, no mistaking the pairing of the plates.

And here is a stack of 2 pairs, plus one shaft keyed plate on top.

I think I have established that the plates are in pairs 🙂

I’ll post pictures of the wear patterns on the plates and try and relate that to the pairing of the plates in the next part. All comments and corrections welcome.

Vanagon – radiator replacement

Last week I swapped new radiator into my friend Simon’s 91 syncro westy. What forced this swap was the failure of the threaded insert where the fan thermoswitch goes. We were trying to install a new switch (old switch was not working properly) and the insert just gave up the ghost.

So Simon left the van at my house and came back a few days later with a new rad and I had the pleasure of doing the install. A bit of background on this van’s radiator, about a year and a half ago we did the thermoswitch replacement, the story is told here. I think I should have nagged Simon a bit more to get a new rad back then, that eroded switch could not have been a good sign.

Removing the rad is a pretty straightforward, if messy, job.

– drop spare and remove clamshell

– clamp off coolant lines

– disconnect wires to rad fan

– remove upper and lower grills

– disconnect thermoswitch (obviously I did not need to do that!)

– remove the (probably rotten) cardboard wind deflectors from around the rad

– I found that removing the passenger side “L” bracket ( 2 X 13mm bolts) first allows you to get access to the spring clamps on the coolant lines, leave the driver’s side bracket untouched for time being to hold the rad in place. Passenger side bracket removed:

Note: see the rubber washer on the plastic”tit” between the coolant hoses? There is a tit on each corner of the rad, the upper ones fit into holes in the van body, the lower ones into holes in the “L” brackets. Don’t lose the rubber washers. Well, go ahead, lose them. Garden hose washers would probably make an ok substitute.

Driver’s side bracket still in place (pic taken before I removed the lower cardboard wind deflector):

– cut or undo any cable ties holding up the coolant hoses or the fan wiring so that the radiator will not hang up when it comes down.

– remove the driver’s side “L” bracket. Careful, the rad will drop down.

– drag the bugger out from under the van and swap the fan and shroud ( 10 mm self tapping screws) over to the new radiator.

Installation is harder than removal as you have to fight gravity and get those upper tits into the holes while lying on your back below the van. A helper at this point would be, well, helpful. Don’t forget that the driver’s side “L” bracket interferes with the spring clamps on the coolant hoses, and don’t forget to push up on the “L” brackets as you tighten the bolts to make sure the rad is seated tightly.

Now the fun part, Sawz-All plus Simon meets the old rad. He cut it in half then cut the plastic end caps off. We found the remains of the threaded insert and a whole lot of gunk at the bottom of the rad. Remember it is a 2-pass rad, hot comes in and directed by end cap up to upper half of rad, then it goes across from passenger to driver’s side and down the other end cap, then back across lower half. The junk was found in the lower, passenger side, ie just before the exit and just below where the thermoswitch (rad fan) is installed.

Note: I drained all the coolant and flushed the system on this van, then recharged with fresh coolant. I found bleeding the Vanagon and Subie EJ25 combo to be much more of a chore than stock or my old inline four in my ’82 westy.

Vanagon – local meet November 2011

A hardy few met at Beaver lake today. All Westies (if I can include my conversion), three syncros and two 2wd. One Tdi, one Bostig, one 2.5 Subie, and two stock wasserboxers. Was fun to kibitz and see each other’s vans.

Vanagon – D15 connector issue

Posted by albell in syncro, vanagon, vanagon mods on November 2, 2011

Yesterday, driving the ’86 syncro, going down a long hill and the van died (noticed when throttle re-applied). Pulled over and it started back up after a couple of tries, funny I thought. Got to my destination and parked for a few hours. Then I tried to start the van and it turns over and catches for a second then dies. Try again, same, then subsequent tries has it turn over but no start. Noticed no fuel pump noise with ign on (and my van does cycle fuel pump with ign on.)

Looked in the engine compartment with ign on. No hum from idle valve. Pulled the fuel pump and ecu relays and replaced with new (during which I jumped contacts and did get fuel pump to run). No change, no idle valve hum and no fuel pump, and no start.

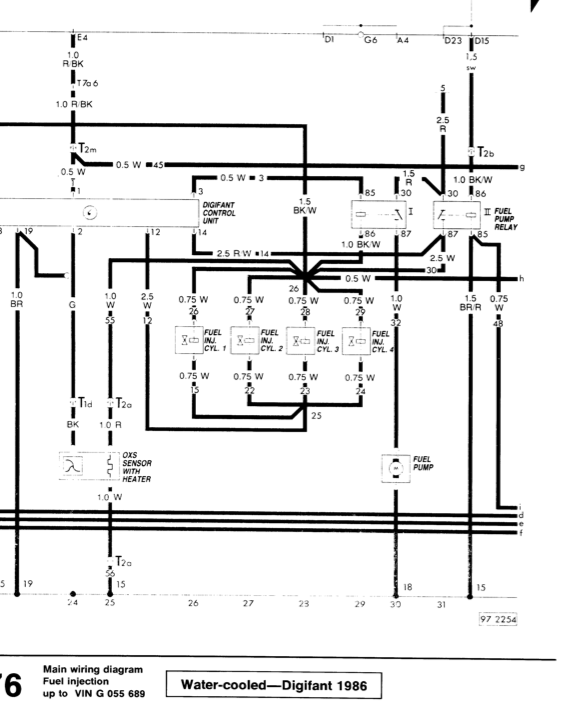

Then I pulled cover from fuse panel and pushed on fuses and generally jiggled panel. Fuel pump cycled on, and I could start the van. Drove home with no problems. I suspected the known problem of the D15 connection on the back of the fuse panel. This connector supplies power from ign switch back to engine compartment and can power (depending on van year and VIN) the fuel pump relay, the idle control unit, coil, and the crankcase breather heater. Gets a little muddled in that the crankcase heater was retrofitted to early ’86 vans (and that seems to be the situation in my case). The wiring diagram shown below is specific to my van.

No matter what version you have, the D15 connector is oveloaded. Note in the diagram there is another connector in the “D” plug that is on same current path as D15. This unused connector, D23, is a bigger Molex than D15. Today I pulled the fuse panel down and removed the “D” plug. D15 looks like it has overheated.

I couldn’t find a spare larger Molex connector to make the switch over to D23, but I did put a new connector on the black wire to D15 and spliced in a pigtail so that when I get the right connector I can plug in to D23 (see the unused larger hole at the bottom?).

Update: I did finally find a large female, molex type, connector for that pigtail, and it is installed into D23.

I can’t say for sure that this connection was responsible for my no start problem yesterday, seems likely though.

Addendum: dug up the Samba thread on this subject, worthwhile reading.

Vanagon – syncro viscous coupling replacement

Posted by albell in syncro, syncro specific repairs on October 23, 2011

I pulled the front diff. on the syncro today to replace the old failed (weak) viscous coupling (vc) with a good used one. Dropping the diff. is in the Bentley manual so I won’t describe that part except to say that it takes a bit of wiggling to get it out. I used a motorcycle lift as a transmission jack. Once out I set it on a container to drain.

See the dark dirt on the input end? Looks like the oil seal there is leaking, need to attend to that. Once most of the oil drained out I humped it onto the bench, just to look at it.

See the speedo drive sticking out? Then it’s on to the floor and off with the 13mm bolts holding the skinny end on.

Some tapping with soft faced hammer to break the seal and it comes apart.

Yup, that’s the vc sitting there, with a spacer on top.

The vc just lifts right off, exposing the speedo drive gear on the pinion shaft.

Closer view of speedo gear.

With the case separated I drained the remaining oil, applied some sealant to the mating surfaces, put the new vc on the pinion (and didn’t forget the spacer) and the skinny part of the case re-installed and torqued down. All well and good, refill with oil in the morning. Now the interesting bit. I had to take the end plate off the old vc, I was dying to see the inside first hand. The big C-clip came out easily.

That end plate should then pull out, but it wouldn’t come. I thought maybe if I drained the vc and also run an awl around the edge of the plate to remove gunk it might help matters. The silicone flowed out, not as viscous as I have seen in those German videos showing refills, and looking like it might have some gear oil in it. BTW, didn’t smell bad.

Got the end plate off.

Removed the C-clip on the shaft (barely visible in above pic) and pulled the first two plates out to look at the adjacent surfaces. Need any more evidence that the plates do come in contact during hump? Upper plate in pic has been flipped over.

Close ups.

Accepted wisdom is that a weak vc is due to the silicone fluid leaking out. One could expect an O-ring to fail with time, but what I found was something else. I had a look at the X-ring that seals around the central shaft (there are two, one on each end, the one shown is in the end plate). It appears that the X-ring is twisted in the groove, look.

Out it comes, yes, it is twisted.

Another view (damned cat hairs, get everywhere).

This surely must have happened at the factory, a lip of the X-ring getting caught on the shaft during assembly. Tsk, tsk, Steyr-Puch.

Addendum: I’m assuming the vc had leaked some fluid, but even with that folded X-ring I have no proof. The “dirty” fluid from the vc could be gear oil contaminated or it could be metal particles from the plates. Perhaps I can use a magnet to determine?

Vanagon – A viscous coupling

Posted by albell in syncro, syncro specific repairs on October 12, 2011

Thanks to good friend Simon, I have, in my hot little hands, a used viscous coupling. It might be on its way out, getting aggressive after a long hot drive, but it will be great for me this winter.

Here is a view of the front, the front differential end.

A couple of things to note:

-the punch mark up there on the rim between the circlip ends. It aligns with the casting ridge between that screw port and the rim.

– the paint on the screw ports and on the circlip ends.

Closer shot of the punch mark on the rim

The punch marks and the paint on the circlip must have something to do with registration on end cap for balancing. I doubt they were there to help rebuilders, but rather I am guessing the unit was balanced before filling (there are spot welded balancing tabs on the side of the body) and the marks are there to be sure it went back together balanced.

Here is the other end, the one closest to the propshaft.

Coming soon, the install, and perhaps (if I can get my act together) some sort of bench test of the VC.

Vanagon – steering arm boot and radius arm sleeve

Posted by albell in syncro, syncro specific repairs, vanagon on September 19, 2011

It all started so easily, replacing a torn steering arm boot (same boot in all Vanagons).

I figured if I removed the ball joint end of the arm from the steering knuckle I could pull the boot off over it and and not change the arm adjustment (toe in). Out to the ball joint at that end, castellated nut with cotter pin.

I pulled the cotter pin and unscrewed the nut, then screwed the nut back on backwards to protect the threaded end, gave the steering knuckle around the ball joint a couple of good raps with a heavy hammer, then rapped upwards on the nut and the joint popped free. Nice when it happens so easily.

The boot was held on by 2 metal clamps (Oetker?) and I snipped the crimped part with some wire cutters and then pulled the boot out towards the ball joint.

That rubber doughnut on the arm locates the outboard end of the boot. The new (well, used one I had in my parts bin) went over the ball joint and up to the rack. Oh, I did put a bit of grease on the exposed ball joint on the inboard end of the steering rack. I used cable ties to secure the boot the the rack and the rubber doughnut.

Now the interesting part, while under the van I decided to have a look at that side’s radius arm rubber bushing and inner sleeve. These parts do wear out, and the sleeve rusts. I undid the drop link from the sway bar to the radius arm, the 19 mm nut at the out board end of the radius arm (inner bolt not touched, to keep the castor unaffected), and the 3 X 19mm bolts that holds the radius arm to the steering knuckle. As suspected, the sleeve was badly rusted and the bushings shot. The subframe hole also was rusty, but still sound underneath. Pretty well the same set up in 2wd Vanagons, its just that the syncro has that front subframe. Neil has a great write up on fixing his damaged radius rod mount on a 2wd Vanagon.

So I have to get new bushings, but right now I decided to make a new sleeve. The dimensions of the sleeve (found on this Samba thread) are: 56 mm long, 25 mm OD, 19mm ID. I did not have any pipe that was close to those dimensions but I had some stainless steel shafting from the scrap yard. It’s not the most efficient way of making a sleeve I admit.

etc…

I could have made a few pot scrubbers with the swarf. The finished sleeve beside the rusty one (btw, the stock sleeve looks like welded tube, and only rusty on the outside).

I slathered everything with a homemade Waxoyl concoction and put it all back together. I’ll order some new bushings.

Recovery Gear

Amazing what you find when you start cleaning up the workshop. If I lash this to the front of the van will it get me in tight with the Landrover guys? 🙂

Vanagon stock wheel and tires

German pdf listing the stock wheels sizes and tire specifications from the factory for 2wd, syncro, and 16″ syncro.

Vanagon syncro – transmission oil change with complications – Solved!

Posted by albell in syncro, syncro specific repairs on July 1, 2011

A week and four (!) attempts later I finally have the leak fixed. It’s a tale of woe and I guess you could say blindness on my part. When I re-installed the cover plate and noticed the drip at one of the lower cover bolts I assumed the leak was coming from a poor seal at the plate. So I drained the oil and left the cover plate off overnight. Next day I cleaned the mating surfaces well with brake cleaner and used Permatex grey RTV on the sealing surface. Filled the transmission and it still leaked, a small drip at one of the cover plate lower bolts. Now I was peeved. Emails to Daryl at AA Transaxle gave me some confidence, he suggested that I make sure that the cover plate was flat and that the 6 mm socket head bolt under the cover plate was good and tight. So once again I drained the transmission (cover plate off again) overnight. Next day I set about making sure the cover plate sealing surface was flat. I tried flat filing but even with the file loaded with chalk, aluminum filings would ball up and scratch the surface.

So I switched to lapping the cover on a bit of granite using a couple of grades of carborundum grit and WD40 as a lube.

Coarse grit:

Finer grit:

You can see a few larger scratches, must have had some coarse grit carried over. But that doesn’t really matter in this situation, what I wanted was the the cover plate sealing surface to be flat.

Back at the transmission I removed the old silicone sealant which what I thought was squeeze out from the original install of the cover plate, right adjacent to the cover plate hole rear side. This was where I was blind, I should have thought more about why there was so much clear silicone there. I also carefully filed what I thought were slight ridges around the bolt holes on the cover plate sealing surface. Here is an example (you might guess that I was grasping at straws here):

Filed:

As another example of me being gormless, I even smeared some RTV on the area where I removed the old silicone caulk on the case seam. Why did I not put more on and further up the seam? I don’t know.

Cover plate was caulked and put into place.

I was generous with the caulk – well that’s what I have been told 🙂

I let the stuff cure for about 5 hours before I filled the transmission with oil. Can you guess what happened? Yes, still a little drip. Chagrin does not adequately describe my feelings at this point. I went under the van and looked carefully and I noticed oil seeping out from the top edge of the little it of RTV I smeared on the case joint (pictured above). If I put a corner of a rag on that spot the drip at the lower bolt would stop. Why had I not noticed this before. More info from Daryl and a sinking feeling that I might have to pull the transmission and reseal the case joint. But I decided to make one more attempt. Again, an overnight drain of the oil and this time I scrubbed and degreased the case joint all along the side of the cover plate hole. I bought some of the expensive RTV sealant, “The Right Stuff”, it had a few good recommendations and is a fast curing goop.

Picture here of the cleaned area (cover plate sealing surface was later cleaned of the old grey Permatex):

I also gave that socket head bolt another bit of twist. Then I smeared on sealant over the case joint, and on the cover plate sealing surface, not very pretty:

I let the stuff cure for a few hours then refilled the transmission and went into town on errands. I was not optimistic about success, but I’ll be dammed if the damn thing is now sealed tight! One day later and it is still dry. I’ve come to the conclusion that the original silicone caulk that I removed from the case joint area was put on to stop a leak. I bet it was done when the transmission was rebuilt.

I learned a few things from this fiasco. Apart from being more observant I discovered that when putting on the skid bars/plate on the syncro, install the bolts loosely until all are in place, before tightening. That makes it so much easier. I also found that my Snap-On transmission wrench (17 mm hex) was awkward to use on the fill plug (but very good on the drain plug) so I cut a section off my 17 mm allen key and used the short bit on a 17 mm socket, and even better, on my 17 mm ratcheting spanner.

Vanagon syncro – transmission oil change with complications

Posted by albell in syncro, syncro specific repairs on June 24, 2011

A very brief overview of a transmission oil change in my ’86 syncro. I had not changed the oil since I bought this van almost 2 years ago and I noticed a very slight oil leak/seep at the bottom edge of the reverse gear cover plate. I figured it would be worthwhile when I had the chance to drain the oil and look at the cover plate. I bought some regular run of the mill 80/90 wt gear oil with the idea that I would put in the fancy gear oil later after I fixed the cover plate leak. As it turned out, this was a smart move.

The oil fill port is on the right hand side of the van just above the shift linkage rear bushing. The drain port is near the rear near the midline. Important to first see if you can unscrew the fill port before trying the drain port. To get at the fill port easily I found it best to remove the rear skid plate/bars; 2 X 17 mm nuts and bolts at the engine carrier bar, 2 X 17 mm bolts and 2 X 17 mm nuts and bolts at the forward end of bars( actually there is a 15 mm nut on the upper left hand skid bar mount), and to detach the shift linkage rear bushing housing; 2 X 13 mm nuts and bolts.

Kinda silly picture of skid plate out.

Oh, I should mention the tools I used to remove the drain and fill plugs. A 17 mm allen key, and a nice Snap-On tool with 17 mm hex. I needed the allen key to help the Snap-On tool at the fill plug, there was not enough space to fully swing the wrench (you know what I mean).

And more obvious advice: clean out the hex recess in the plugs with dental pick, toothpick, compressed air, whatever. Ya gotta have the wrench make a good fit. I squirted penetrant/rust buster on the plugs, more out of habit than expecting that the damn stuff actually does anything. Next pictures shows the fill plug (shift linkage still up in place) and the wrench in in the plug, riveting story eh?

Thankfully the fill port plug unscrewed with no problem. Next, on to the drain plug. The wet spot is the penetrant fluid stain.

It too came out with no trouble. The magnetic plug had a bit of fuzz on it, but I think this is a pretty normal coif.

While the transmission drained, I removed the weeping cover plate. It seemed to be leaking at the bottom edge.

Plate off, evidence of silicone caulk as a sealant.

Close up of the bottom corner that I suspected the leak was coming from. No smoking gun that I can see, minor scratches, almost a crack like line there though, no?

At this point I was advised by my son that I need to drive him to some sort of “date”, grrr. I should have let the transmission drain overnight and degrease the mating surface of the cover plate before applying rtv silicone and re-assembling (as per Daryl of AA transmission’s advice). So I slapped on the the silicone and the plate, and set about filling the transmission. I made a fill hose with some pvc tubing and a funnel.

All filled and the skid plate back on, the shift linkage re-installed, and the damn cover plate leaks more than before. So, tomorrow I’ll do it all over, this time properly letting the cover plate area drain and be de-greased. Daryl also advised flat filling the cover plate flange to make sure it is flat.

Vanagon syncro aux. back up light installed

Posted by albell in syncro, vanagon, vanagon mods on June 1, 2011

I gave up on making an adaptor for the chrome light housing and decided instead to make one for a rubber housing, here it is.

Made of black polyethylene, kinda clunky looking. Jony Ive does not live here. It does seem to work though.

I led the power and ground wires through one of the holes in the rear valence, up over and well away from the muffler, and through a grommeted hole in the heat shield. I do wish there was a better route. I used one of those black plastic electrical box to house the relay.

I used wire I had lying around, not conforming very well to any colour code. I did use a little bus, power is on the right, and ground on the left. I mounted the box onto the plastic “bulkhead” that the air intake snorkel connects to on the right hand side of the engine compartment. I tapped into the black/blue power wire feeding the right hand side back up light to provide the signal power for the relay.

I also put in an old back up beeper I had on my ’82 westy. I was a good thing to have when my son was young and I got used to it, so now it’s on the syncro, just lying in front of right hand side tail lights.

I took power from the alternator stud – NOTE – I have not installed in inline fuse on this feed line yet, one DOES need to be installed. I led a ground to one of the alternator housing screws.

Gack, I need to buy black cable ties. Tested, and works (beeper too).

Vanagon syncro aux. back up light bracket

Posted by albell in syncro, vanagon, vanagon mods on May 31, 2011

I want to put an auxiliary back up light on my ’86 syncro but never have found an attachment method I liked. That is until Brett H. told me about how he did it, so all credit for this bracket idea goes to him. I used scrap stainless stock I had in the workshop (hence the double holes shown) and I have an old bumper that I could do trial fittings on. Pretty simple bracket, easy bends.

It bolts to the bumper using one of the holes that the plastic clips on the rubber “rub strip” attaches to.

The lamp housing is one of a set I found at the Salvation Army some years ago. I had one on the front of my old ’82 westy, fitted with a 250 W aircraft lamp. The test fitting on the old bumper looked ok.

It is possible to attach the bracket while the bumper is on the van.

I enlarged the hole that the plastic clip was set into so that the rub strip would fit over the bolt.

The rub strip fits back on quite well, I was lucky with the hole enlarging, it seems to grab the bolt head.

Attaching the lamp to the bracket showed that I need to tweak things a bit, light is pointing slightly down. I’ll make an adapter tomorrow and show the electrical part of the install. Oh, in the pic above, the bracket is to the right of the license plate (seen on the left).

Vanagon syncro – NOS shifter box

Posted by albell in syncro, syncro specific repairs on May 30, 2011

Vanagon syncro gear shift lever maintenance

Posted by albell in syncro, syncro specific repairs on May 29, 2011

R. Jones pushed me into this, he wanted to see how it all goes together. I’ll go through it on point form, pictures and text. Bentley has an exploded view and instructions for back up.

On the way out to the workshop I noticed a cool spider on a leaf of one of the jade plants we put outside for the summer. Got a quick snap before it moved. If you want good pics, head to A. Gordon’s Wordlessme.

Back to the job, first unscrew gear lever knob and pull off the rubber shifter boot. Then mark the position of the upper plate on the lower plate. I scratched circles through the two holes in the upper plate.

No need to remove the two 10 mm nuts you see there right now, we will be taking the two plates out together. Then it’s under the van to drop the spare and remove the shifter box, four 10 mm nuts and washers, careful, they drop easily 🙂

No need to remove the two 10 mm nuts you see there right now, we will be taking the two plates out together. Then it’s under the van to drop the spare and remove the shifter box, four 10 mm nuts and washers, careful, they drop easily 🙂

Box removed

Now remove the vertical from the horizontal between the “ears”. It’s a 10 mm stover nut and a washer on one side, and a 13 mm headed bolt on the other.

Now you can get back into the van and pull up the plates and shifter, and take it to the bench for disassembly.

There is a set screw on that metal collar on top of that spring, hold it tight as you back the screw off and remove collar and spring. The shift lever will slide out of the housing assembly. Look at the “T” end of the lever, remove the 2 plastic bushings. These are wear items and it would be a good idea to replace them.

I didn’t as I did not have any on hand, and I couldn’t be arsed to make some up. The bolt that rides in there looked a bit worn and I suppose the small amount of play in there does contribute to the overall feel of the shifter. Here is the bolt back in the bushings.

And the wear.

Back to the other parts, now you can remove the two stover nuts holding the upper and lower plates together, you did mark position of the two plates first right? The white plastic collar on the underside of the upper plate is pried out.

Then the entire inner workings, rubber collar and all, can be pushed out from top to bottom. It might be tight, but palm pressure is enough to do it. Careful not to break the upper plastic.

The two white plastic bearing shells can be pried out of the rubber and that will allow an internal spring to sproing things apart.

Now clean all the parts.

Reassembly is pretty straightforward, first squeeze the split shells into the rubber collar, might be a bit of a struggle.

Then the one inner bearing with the protrusion is pushed in from below until it snaps into place. Good time to put a little grease on the rubbing surfaces. Not too much, Bentley makes no mention of lubricating the plastic assembly and I have seen some that are caked in grease and dirt, so it is probably best to go light with the schmalz. Do, however, put a dab of grease on the gear lever where it goes into the plastic assembly and in the bushings on the “T’ at the end of the lever. Note that the rubber collar has a “top”, the little ridge, see? Sorry about bad focus in the next couple of pics.

Then put the larger of the two springs on.

Then put the larger of the two springs on.

And press the upper bearing into place, again it snaps in. The rubber collar allows the split shells to spread.

This assembly is now pushed into the upper plate.

Followed by that plastic collar.

Followed by that plastic collar.

Put the upper and lower plates together and secure (in the right place using your marks) with the two 10 mm stover nuts. I risked Zinc and or Cadmium poisoning and buffed up the shift lever. The lever is inserted into the bearing assembly, the spring put on, and the collar locked down in place (there is a dimple on the shaft).

Put the upper and lower plates together and secure (in the right place using your marks) with the two 10 mm stover nuts. I risked Zinc and or Cadmium poisoning and buffed up the shift lever. The lever is inserted into the bearing assembly, the spring put on, and the collar locked down in place (there is a dimple on the shaft).

Out to the van, and pop the gubbins in.

Then under the van to connect the shift lever to the ears using that bolt and bushing arrangement. Bolt the box back on and put the spare tire and tray back in place. Back upstairs and rubber boot and shift knob back on.

Then under the van to connect the shift lever to the ears using that bolt and bushing arrangement. Bolt the box back on and put the spare tire and tray back in place. Back upstairs and rubber boot and shift knob back on.

That’s it. Oh, I suppose I should have mentioned that you can get replacement plastic parts for the assembly from the usual suspects, Van Cafe, Go Westy, Bus Depot etc. I re-used the old parts, they seemed to be in OK shape.

That’s it. Oh, I suppose I should have mentioned that you can get replacement plastic parts for the assembly from the usual suspects, Van Cafe, Go Westy, Bus Depot etc. I re-used the old parts, they seemed to be in OK shape.

Vanagon syncro front shifter box pics

Posted by albell in syncro, syncro specific repairs on May 28, 2011

For Doug M., wanted to see the wear patterns. Looks in good shape for being almost 25 years old and god knows how many shifts.

Vanagon syncro shift linkage – rear, and a glance at the front

Posted by albell in syncro, syncro specific repairs on May 22, 2011

I’ve been noticing that I sometimes have a little difficulty shifting into 1st and 2nd. Spraying grease on the exposed wear points on linkage under the van makes the difficult shifting go away for a while, so even I got the message that it needed some attention This diagram shows the linkage, my van has neither the shift linkage protective tube, nor the rubber boots protecting the rear bushing.

Another difference is that as well as the roll pin that secures the horizontal linkage to the vertical link right at the transmission, my van also has a horizontal bolt and nut securing the two. The linkage at the rear comes off pretty easily, except that the skid rails on the syncro does restrict access to some nuts and bolts. The roll pin is tapped out with hammer and small drift from the inside of the vertical link, that link drops from the ball link which is attached (13 mm nut) to the shaft coming out of the transmission. On the bench, the manky, dirty bunch.

Then all cleaned up.

The brown ovoid shaped bushing was packed inside with a mixture of old grease and grit, took a few minutes to get that clean. The roll pin is worn, I think I should get a new one ( have a spare bit of linkage so I can get the right size at the shop).

Then it’s grease them up and put it all back into the van, with a spritz of Fluid Film. Not really happy about the rubber boot that covers the transmission selector shaft. It does grab onto a ridge on transmission, but outboard end of it doesn’t seem to attach to anything. You can see a glint of exposed shaft in the pic below.

Shot of the linkage U-joint, which seems/feels pretty good, and the forward bushing which takes a bit more effort to get to.

No road test done to see if the shifting has improved, but parked, it goes into all gears nicely.

While I was in the mood, I had a look at the linkage/joint right under the gear shift lever. You know, hidden by that box above the spare tire. I had been reading this thread on the Samba and was curious.

The plastic ears are in place, and not too badly worn. Trust me, you can’t really see because to the grease.

Cleaned off the old grease and put new stuff on.

Vanagon syncro left hand side transmission mount and breather line

Posted by albell in syncro, syncro specific repairs on May 12, 2011

Still buggering around wondering how to raise the front of the transmission to reduce the output flange downward angle. I supported the front of the transmission and pulled the left hand side mount off. The mount on the other side is much less accessible, coolant lines restrict access. I guess I have to say that this is pretty dull blog stuff. Maybe it helps other folks doing the same thing, but mainly I am treating it as a journal, recording what I have done and reminding me what to do if I have to do it again.

So the rubber mount there is attached to a bracket which is bolted to a beam under the van, and to an ear on the transmission.

It is hard to get a wrench up to the nut on the top of the rubber mounts, but an angle head ratchet wrench (17 mm) can be squeezed in there, and the other end attacked with a socket. I found that loosening the three 13 mm bolts that hold the bracket to the beam allows the ratchet wrench to get up there easier. One funny thing, the EKTA-like diagram above show those bolts coming in from above, they don’t. So the rubber mounts and bracket were pulled out. Here is the bracket on the bench.

I sprayed some white paint on the rubber mount bolt and transmission ear just in case the transmission shifted aand I had to get things back in the right spot. As it turned out, the other mount held things in place.

I compared the rubber mounts, upper and lower (above and below the bracket). The upper one is marked with “U”.

Looks a bit collapsed, saw the same thing with the front diff. mount. The bracket was a bit rusty so I scraped off the rust and slapped some POR on it. While the paint was drying, I had a look at the part of the transmission that was exposed with the mount removed. I found the transmission breather hole which, in the syncro, has a plastic tube leading somewhere higher so that the vent won’t take in water if wading in the van. Sometime in the van’s history the transmission was rebuilt and the breather tube was reconnected to the hose barb on the transmission via a short length of rubber hose. It came off too easily so I used some clear PVC tubing to connect it (heating the stock tubing with heat gun and trying to get it on the hose barb was not a success).

It really is a tighter fit than it looks in the picture, I’m confident it will stay in place. I reassembled the mount, with the lower rubber now on top, and had a few minutes of “quality time” re-installing. I did not succeed in finding any new ideas on adjusting the transmission angle, but I am glad I got the breath line better secured.

PS I also re-installed the “new” propshaft I was babbling on about a few posts back, I had replaced one of the U-joints since. Well, the upshot of all of this was that the driveline vibrations are pretty well gone. Still a very, very slight vibe at 50 kph, but it is really acceptable.

Vanagon syncro propshaft comparison

Posted by albell in syncro, syncro specific repairs on May 9, 2011

Took apart 2 stock propshafts. The rusty red one is an ’86 model, the black one is from a later van (I don’t know the year). You can see that there are a few minor differences. One important one is the machined end that houses the internal bushings. Note the thickness of the internal bushings, the newer shaft has much thinner bushings. Both units have shafts that are the same diameter so it’s the bushing housing that is a smaller diameter in the newer shaft. Also the shaft lengths differ, the older one being longer. The newer shaft has the o-ring in a groove, the older one has a rebate to hold ring.

Some more trivia:

1. the black (newer shaft) had one U-joint that looked stock and one that had a blanked off grease nipple. I am assuming orig. U-joint was replaced

2. The rusty red one, from my van and I am confident that is stock, does match the diagram I posted in previous blog entry. The black one does not match in some details.

3. both internal shafts are same diameter

4. overall length of shafts differ by a couple of millimeters. The black, (newer), shaft being shorter.

5. all the socket cap screws are the same

6. I haven’t found, and this does not mean none exist, any vw part number on both shafts

7. giubos are identical

8. the part of the joint that mates to the trans/front diff, on both shafts are as identical as machined sand cast parts can be

9. the diameter of the propshaft proper is pretty well identical on both shafts (3.155″)

10. both shafts assembled with U-joints out of IN phase

Giubo end of Vanagon syncro propshaft

Posted by albell in syncro, syncro specific repairs on May 8, 2011

I played around with a spare propshaft that I got the other day (thanks again SImon). I installed it in the van as is and it did have a vibration at around 50 kph. Wasn’t a huge vibration, but it wasn’t acceptable. Believe it or not, but it felt like the vibration was to the rear rather than the front. I took the shaft out and set about taking the giubo end apart. First thing noticeable was the U-joint had slight axial play in one of the crosses. I took off the circlips at that joint and they measure approx 0.050 in thickness. I installed a pair of 0.060 circlips and that eliminated the play. The ears of the joint look a little beaten. Also, doesn’t look like the circlip is fully in the groove does it? But it is… I think 🙂

I still could detect play at that end and guessed it might be from wear in the internal shaft and bushings. So the giubo and end u-joint had to come off.

First, here is a pic of the end of the shaft.

If you look closely you can see the head of a bolt in the inside face of the U-joint. This is to plug a grease nipple port and indicates the joint is not stock. Close up of that area.

Before taking things apart, I sprayed some paint on the works so I could put it all back together in the same orientation.

Then off with the bolts that hold the giubo to the propshaft. The giubo and joint pull out. The shaft doesn’t look too bad on the end.

Then remove the bots holding the giubo to the joint.

That end doesn’t look too bad either. You can see the shaft is thicker in the two spots, that’s where it rides on the internal bronze bushings in the prop shaft. Have a look in the hole in the propshaft. There’s an o-ring in a groove at the end. My other propshaft had the o-ring in a rebate, not a groove.

Now the giubo, sitting roughly in place, and it had washers on either side. Pretty cruddy washers, and my other propshaft did not have them.

With the giubo removed from the joint, I reinserted the shaft into the hole and tried it out for size. It felt pretty good, no slop. So where did that looseness come from that I felt when it was all assembled?

I decided to lube it all up and put it back together. I used a band clamp to squeeze the giubo into shape to let me get the bolts back in to attach joint to rubber.

And same technique when attaching assembly to propshaft.

Well, all assembled (minus those washers) and it feels nice and tight. No play like before. So I put it back into the van and had a test drive. It still has some vibration (again around 50 kph) but it is less. I had to say that didn’t I? Honestly it is better but not what I want. So the shaft is coming off again and I’ll take it to the driveline shop for spin balancing.

Addendum: In the comments Rob advised replacing that U-joint. I agree and I should have mentioned this in the post. I’ll ask the driveline guy to do it this time.

More addendum: Diagram of the end of shaft. Does it look to you like of some sort of cap at the end of the internal tube or is it integral to the inner bushing? I’m thinking the former is the case. Also note that it is a nut and bolt that holds the giubo to the U-joint yoke. In the propshaft above its a bolt, with the propshaft yoke having threaded holes. My other propshaft has same attachment method shown in diagram. No washers between giubo and shaft shown on diagram either. I bet there were some minor changes made to the shaft during production.