Posts Tagged syncro

Bleeding failure

After refurbishing the pedal assembly I had to bleed the brakes. The rears went ok, but I broke the bleeder nipples from both front calipers. I swear I didn’t wrench hard, was a short wrench and the buggers sheared of easily. Here is pic of the front right, stub of bleeder gnarled a bit as I had a go with vice grips.

I tried spiral type bolt extractor but no luck. I then started to drill, carefully, not full diameter which is 7 mm, and not full depth. I was worried about damaging threads and also the conical base of the hole that forms the seal with the conical point of the bleeder. I then hit it with lots of heat, hoping the shell of the bleeder would separate from the body. No such luck and I got more frustrated and drilled wider and deeper.

I ran a tap down the hole and managed to get some threads restored, but in the end I drilled out too deep and damaged the conical seat at the base of the hole and a new bleeder screw would not seal. Double bugger. Tomorrow I am off to the local wreckers to get a couple of used calipers. What a pain.

Vanagon dash removal, pedal assembly repair, and heater core flush

Posted by albell in syncro, syncro specific repairs, vanagon on February 1, 2011

I’m just about finished with this project. I decided to pull the dash and have a look at both the heater core (I didn’t have as much front heat as I thought I should have) and to fix a squeaky clutch pedal. Removing the dash has been covered elsewhere, a good reference is on Ben’s Place website. Once the dash is out, the heater box can be removed (clamp off coolant lines). One tool that makes this possible is a phillips bit socket on a long extension. Some of the screws holding the heater box to the van can be rusted in tight, so take care. The heater box is then split along the seam, there are spring clips to remove first (and welded plastic tabs if box has not been split before). Then the heater core comes out and I cleaned it inside an out with a hydrofluoric acid based aluminium cleaner. I diluted the cleaner, it was a pretty strong stock solution. Flushing with the cleaner produced a lot of black sediment, I’m hoping that getting rid of that stuff will improve the heater’s performance.

Dash off and heater box out:

Core before cleaning:

The other side:

And a shot of one side after cleaning and installed in box:

Also took the opportunity to squirt some oil on one end of the heater fan. It did feel easier to spin after even this casual oiling:

With the dash off its relatively easy to pull the pedal assembly out (after draining brake fluid etc). I have a spare assembly that I rebuilt and talked about in this post, but I decided rather than swap over the units I would rebuild this one. As in the other one, this assembly had a worn hole in clutch pedal and worn clevis pin.

But also, the clutch rod was bent. Wonder how that happened? Maybe previous owner had replaced clutch master cylinder and didn’t insert pin correctly and the first time pedal was depressed it bent the rod before it popped into place?

I took the chance and straightened it out, then I enlarged the hole in the clutch pedal and clevis to make it round rather than oval, and turned a new, oversized, (and roughly finished) pin.

Cleaned everything up, greased, and reassembled.

The pedal feels a whole lot better. Now the chore of putting it all back into the van. Nothing special to report here except to note that it is easier to reattach the clutch line to the clutch master cylinder if the mc is disconnected from the pedal bracket. Oh, and a heat gun is needed to soften the plastic vacuum line to the brake booster to get it off, and to put it back on. The dash is back in place and tomorrow I’ll be reconnecting the electrics and flushing the hydraulics.

Vanagon clutch and brake pedal assembly

How can I introduce this? Why not just say that after some time the Vanagon clutch and brake pedal assembly wears a bit at certain points and its a bitch to repair in the van.

My ’86 syncro has a squeaky clutch pedal and I know why… the metal arm of the pedal has a hole in it where a pin connects it to the clevis of the clutch master cylinder slave rod, and this hole wears into an oval over time. The pin also gets worn. The result is a less than smooth and silent clutch pedal.

I happen to have a complete assembly taken from my dearly loved ’82 westy that I could work on and refurbish.

On the ’82’s clutch pedal the hole was indeed oval and the pin worn (pic of pin in vise is the original worn one). So I drilled out the pedal hole to make it round again (others have filled in hole with weld and redrilled to stock size), also drilled the clevis hole, and I made a new pin out of some stainless stock. Like an idiot, I forgot to take before pics. But the series of after pics show the disassembled assembly and the whole shebang together again. A close up of the clutch clevis and pin included.

One day I’ll swap it into my syncro (it probably means dash removal, but some rumours of being able to get it up and out via binnacle are about). Maybe before I do that, I’ll swap the brake booster for a larger one from an E30 series BMW (see Herman’s blog linked to the right for details).

Oh I should add, if you are like me and can’t be arsed to pull dash to get pedal assembly out for refurb, or at least greased, then you can try scrootching under the dash to get at the bugger. If you lie across the floor, or half in, half out the drivers door, you can reach up with one hand and feel where the clutch actuating rod/clevis connects to the cross pin. You might have to move the clutch pedal with other hand to really get at it. If you put a blob of grease on your finger you can try to massage it around the pin.

Viscous coupling rebuild

Posted by albell in syncro, syncro specific repairs, vanagon on August 16, 2010

In German, on this site http://www.2wd-goes-syncro.de/. Videos showing a VC being taken apart, cleaned, and new fluid added. Well worth a look.

Camperisation Part 2

Posted by albell in syncro, vanagon, vanagon mods on August 11, 2010

I did some trial fittings and screwed down some cabinets in final positions. Made a spacer for bracket that holds pass. side of rear bench to wall of van. I mentioned in “the start of camperisation” post that the rear bench did not fit as tight to the wall in the syncro as it did in the ’82 Westy. The spacer allows the bracket to be used and bolts the bench tight to the wall.

Wardrobe actually fit in without cutting headliner. Bracket at back on engine deck is fixed in place, and wardrobe is bolted to next cabinet and that cabinet is bolted to rear bench. Its alll pretty secure even though low cabinet not attched to van wall yet and also the rear bench is not bolted down to floor yet.

Overhead cabinet bolted to wardrobe and held up on other end by prop until I figure out a support bracket to hold it to ceiling and to pass. side wall. In the Westy, its bolted to flat ceiling (plywood) which is the upper bunk. You can see how the ceilings differ in that there is a space between overhead cabinet and the ceiling. The Mosaik “kit” has a differently shaped cabinet face to account for ceiling difference. (I can’t seem to find a pic of that modified cabinet right a the moment) I will have to do something to fill gap between cabinet and ceiling.

Apart from little fitment issues, the cabinets went in pretty easily. Next step is making holes for propane lines and watertank and sink drains.

Syncro fuel filter replacement, Part 2

Posted by albell in syncro, syncro specific repairs on August 4, 2010

Got the new filter today, and after working on my wave maker project I set about putting it in.

Installed into bracket.

Tucked behind spring tower, fuel line outlet attached first.

Then filter pulled forward towards front of van and inlet line attached. The the bracket moved into place and attached to tower with the screws. Do the rear screw first, then the front screw. Rear is towards rear of van, front is towards front of van.

Next is reinstalling carbon filter/canister bracket.

And finally the canister itself. I think I installed it higher on the bracket than before, but I don’t think I have crimped any of the lines at the top of the canister.

Overview shot of area.

In hindsight, I guess its not that bad of a job. But I can imagine it being hell with a van that has seen more salty winters. While I was in there, I removed an A/C line and the A/C drier that sat behind the charcoal canister, I’m stripping all the A/C stuff from the van.

Rear seat/bed bracket attachment

Posted by albell in syncro, vanagon, vanagon mods on August 3, 2010

I mentioned before that just drilling a hole through the sheet metal of the rear deck to attach the rear seat/bed brackets is not good enough to get a firm connection. The screws used are self tapping screws which sort of implies, I think, that the factory did not weld on nuts on the underside of the sheet metal. Looking closely into the holes in my ’82 Westy the metal appears thicker than in the same place on my ’86 syncro. Here is view from inside of van of one of the brackets in place (in place but askew).

So I set about making some little backing plates to give the screws more thread to love. I used 3/16″ thick stainless bar to make to little plates, 3/4″ wide, 1″ long and a hole in each tapped for 6 X 1.00 mm thread. My plan was to use some Sikaflex to glue the plates to the underside of the deck so that the would stay in place when I screwed the the brackets down. Here is exciting picture of one of the “plates”.

And here is one of the little chaps stuck up in the passenger side rear wheel well where the right hand bracket screw comes through – boy am I slow, it just occurred to me now to check the same place in the Westy to see if there is any similar thing going on. Edit: I just looked at the passenger side rear wheel well on my ’82 Westy where the bracket screw comes through, and lo and behold, looks like a nut is there, surrounded by goop. I assume same thing done for other bracket. So I am not completely mad thinking my little plates will work.

My plate:

Westfalia’s version:

On the driver’s side, the screw comes through above and behind the gas tank of the Syncro.

And here is the plate in place, all smeared with Sikaflex.

I’ll let the Sikaflex cure overnight and then I will remove the screws and I hope the plates will stay in place.

Syncro fuel filter replacement, Part I

Posted by albell in syncro, syncro specific repairs on August 3, 2010

The design team responsible for the fuel supply system in the Vanagon Syncro was led by a descendant of Leopold von Sacher-Masoch. No? Well how do you explain the location of the fuel filter then?

In camperizing the syncro I came upon the problem of screwing down the folding bed/rear bench brackets to the rear deck. I mentioned in a previous post how I drilled and tapped holes, but the rear deck is not thick enough to get more than one complete thread in it, so I went about making some little backing plates to build it up. On the passenger side it is no problem, the area is in the wheel well. But on the drivers side you have to reach up in wheel well, past the carbon filter and behind/above the gas tank. While doing that I decided to change the fuel filter which is located in that region.

Actually the fuel filter is attached to the inboard side of the spring tower. But you wouldn’t know it from this diagram (its #25, oh and the charcoal filter which is part of the emission control system is not shown here).

I did not take an “establishing shot” type pic, but here is a close up of the front side of the spring tower and the charcoal canister (I had removed the gear clamp that holds the canister to its bracket, which in turn is screwed to spring tower).

With the canister moved out the way a bit, you can see the filter, inlet end.

And if you peer around the rear of the spring tower, you can see the filter outlet end.

And if you peer around the rear of the spring tower, you can see the filter outlet end.

See that screw end sticking out? its one of two 10 mm hex headed screws that holds the filter bracket to the spring tower. I took both out, the “other one” near the front side of the tower is a bit awkward to get at, but I was lucky in that they were not rusted in. By the way, I did squirt all the fasteners with some rust busting stuff before starting. Hello bracket end!

See that screw end sticking out? its one of two 10 mm hex headed screws that holds the filter bracket to the spring tower. I took both out, the “other one” near the front side of the tower is a bit awkward to get at, but I was lucky in that they were not rusted in. By the way, I did squirt all the fasteners with some rust busting stuff before starting. Hello bracket end!

I clamped the inlet and outlet fuel lines at this point too. I could get at the gear clamp at the outlet side so I removed that hose from the filter.

I clamped the inlet and outlet fuel lines at this point too. I could get at the gear clamp at the outlet side so I removed that hose from the filter.

Then I struggled with pulling the filter forward, towards front of van, and down to get it out.

Then I struggled with pulling the filter forward, towards front of van, and down to get it out.

The above picture shows how it doesn’t come out. The charcoal canister, like an annoying relative, kept getting in the way, and the canister’s bracket to the right prevented the filter from coming out… oh wait, why not remove that dammed bracket, doh. Again, two 10 mm hex head screws, and the bracket is off and the filter and its bracket comes out.

The above picture shows how it doesn’t come out. The charcoal canister, like an annoying relative, kept getting in the way, and the canister’s bracket to the right prevented the filter from coming out… oh wait, why not remove that dammed bracket, doh. Again, two 10 mm hex head screws, and the bracket is off and the filter and its bracket comes out.

I removed the filter from the bracket, sent the bracket and the charcoal canister bracket into a wash of naval jelly in preparation for painting. Here is the filter still in its bracket and beside it, the charcoal canister bracket.

I removed the filter from the bracket, sent the bracket and the charcoal canister bracket into a wash of naval jelly in preparation for painting. Here is the filter still in its bracket and beside it, the charcoal canister bracket.

Part number for the fuel filter is 450 905 030. Its used an a number of VW vehicles from the 80’s/90’s, should cost around 10 – 15 bucks.

Part number for the fuel filter is 450 905 030. Its used an a number of VW vehicles from the 80’s/90’s, should cost around 10 – 15 bucks.

Freed from its bracket, the filter underwent surgery.

The exposed paper filter elements were incised then retracted.

The exposed paper filter elements were incised then retracted.

Yuck. I bet its the original filter.

The brackets are painted and now drying, tomorrow the new filter goes in. See that in Part II

Syncro Westy – rust treatment and Zetec engine

Posted by albell in syncro, syncro specific repairs on June 29, 2010

Whereas I just poke around the fringes of syncro repair, Ed In Vancouver goes deep with rust repair and a Ford Zetec engine swap. His website is here.

prop shaft alignment quick test

Posted by albell in syncro, syncro specific repairs on May 23, 2010

I had time today to do a quick check of the alignment of my prop shaft, or rather where the prop shaft goes, as I have it out right now…

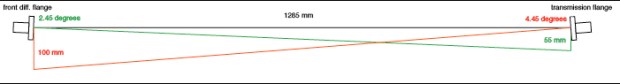

I have to reiterate, this was a quick test, approximate measurements only. I attached my laser alignment jig to, in turn, the transmission output flange, then the front diff. input flange. Each time I measured down from the centre of the opposite flange to where the laser dot was. I also measured the distance between the centres of both flanges.

I did not measure any lateral alignment this go round.

What I found was the front diff was pointing down at a lesser angle then the rear transmission, 2.45 degrees vs 4.45 degrees. Ideally the angles should be equal and less than 4 degrees (but not zero degrees).

Here is a diagram of my results:

If you slept through trig, what you need to know is the TOA part of SOHCAHTOA. TOA means tangent = opposite over adjacent. For example in diagram above, for transmission flange, the tangent of the angle is 100/1285 -> 4.45 degrees. Just do the 100/1285 bit on your calculator then hit the tan-1 button.

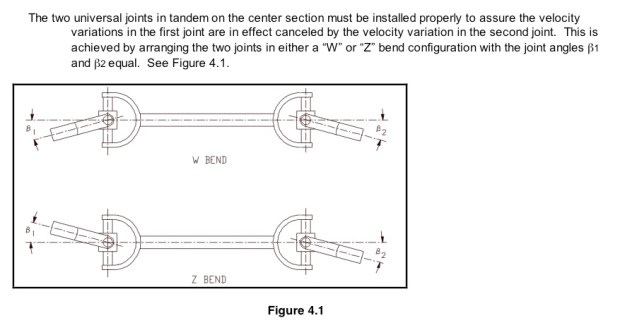

Here is a diagram of how U-joints can be oriented:

You can see how my syncro is in the “W” bend form, but the 2 angles are not equal. The angles must be equal, or damn close, to eliminate vibrations. This means I have to adjust the angle that the front diff. sits by shimming the front mount.

Request for viscous coupling

If anyone has an old clapped out viscous coupling they would like to donate, please leave me a message in the comments. I’d like to take one apart, look at the seals, the plates etc.

Syncro running gear layouts

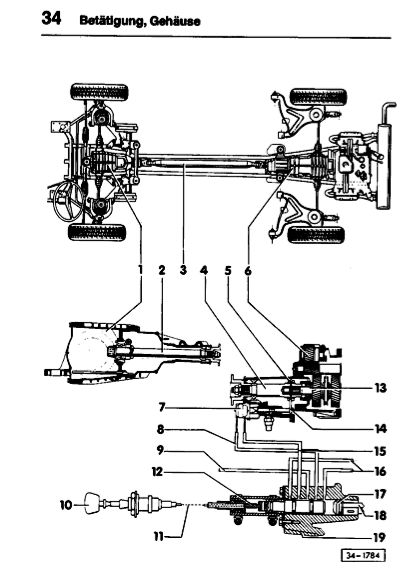

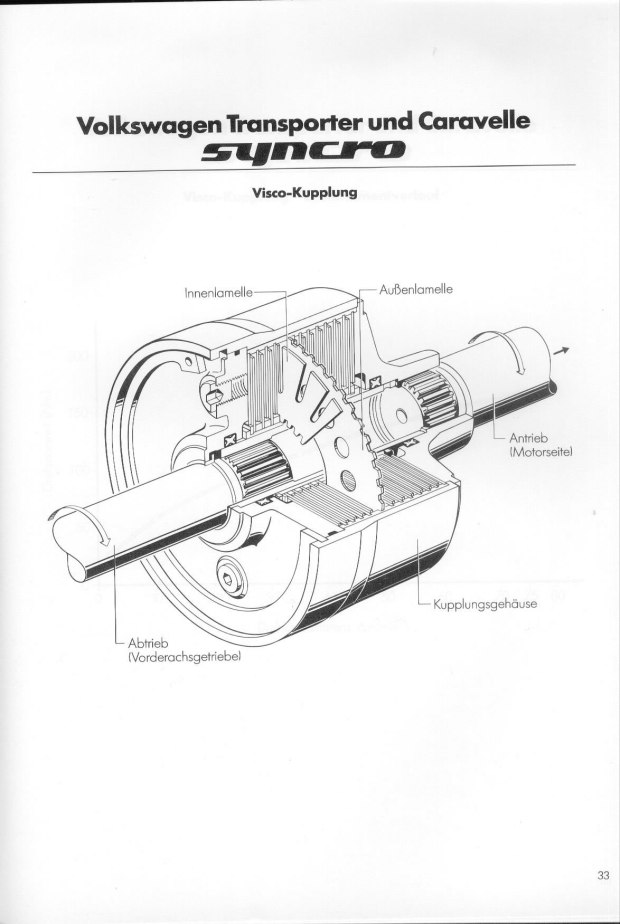

Nice to see it all laid out like this. First we have an overview of viscous coupling installed driveline. This has both rear and front differential locks.

And here we have the much much rarer version. No viscous coupling, where it was is now a straight shaft. Power to front is now controlled by a de-coupler housed in nose cone of transmission.

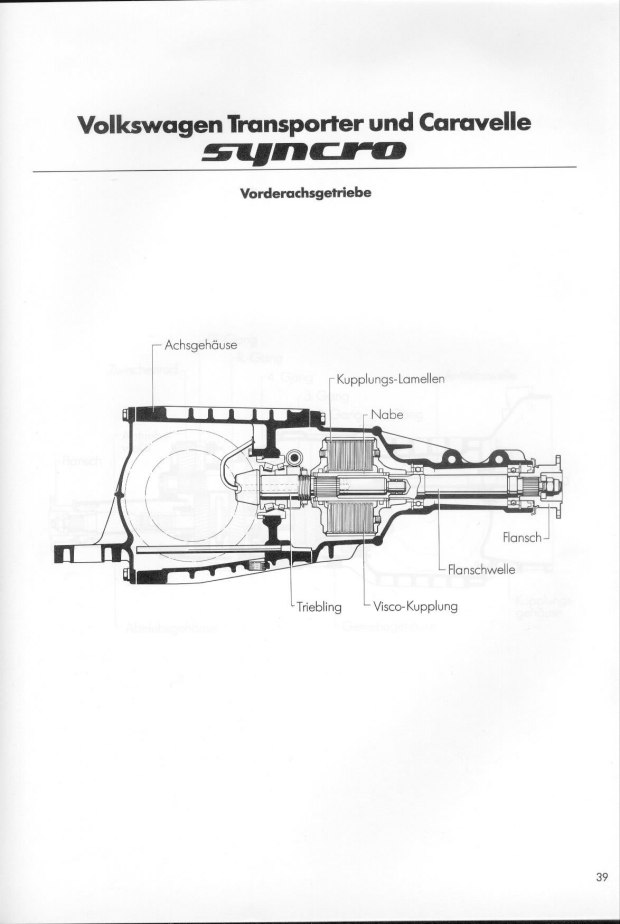

And here is cross section of the front differential, showing viscous coupling install.

And a cross section of the rear differential and transmission.

Syncro front diff. removal

Posted by albell in syncro, syncro specific repairs on April 3, 2010

Look, its cold and windy today, hail at times. I don’t want to freeze in my cold workshop so I am sitting at the computer, ok?

Courtesy of Kafer and Co., Homburg/Einöd is this pdf file showing how to remove your syncro front differential when you want to swap in that new or rebuilt viscous coupling. PDF with pictures, about 800 kb.

A wide open viscous coupling

Graphic shots here from the Wikipedia entry on viscous coupling. I think they were supplied by some English chap who cut open a failed unit. Note the colour of the fluid, I wonder if this colour is due to old age break down, metal particles, or its the stock colour for the polymethylsiloxane and any additive the maker adds. The plates have either notches on the outside (engage with VC housing and flange shaft), or on the inside (engages with pinion shaft). The piercings on the plates are there to reduce heat induced warping. I think its the tiny burrs produced when those plates are pierced that are referred to in the abstract posted previously.

Might as well throw in a sectioned diagram of the VC to perhaps make things more clear.

More on humping

Link bait title, teasing just like this abstract I found. Full text not available but it explains more about how the burrs formed during the piercing of the plates act in the humping state. Also interesting note at end about temperature mediated viscosity changes, something I have been railing against as the cause of torque transfer in the VW vc. I’m sticking with that opinion until proved wrong 🙂

Title:

Numerical analysis of torque augmentation in viscous couplings

Authors:

Pan, Chen

Affiliation:

AA(SYRACUSE UNIVERSITY)

Publication:

Thesis (PhD). SYRACUSE UNIVERSITY, Source DAI-B 59/07, p. 3659, Jan 1999, 153 pages.

Publication Date:

00/1998

Category:

Engineering: Mechanical, Applied Mechanics, Physics: Fluid and Plasma

Origin:

UMI

Abstract Copyright:

(c) 1998: UMI Company

Comment:

Publication Number: 9842398; Advisor: Lewalle, Jacques

Bibliographic Code:

1998PhDT…….126P

Abstract

The humping phenomenon in viscous couplings is investigated by the finite element method. The possible destabilizing factors suggested by the experimental results are divided in two groups: fluid properties and plate geometry. A simple two-dimensional model capable of including these factors was devised. Both Newtonian flow and Non-Newtonian flow in the viscous coupling were solved by our Finite Element Method code. The finite element formulation based on the variational principle is discretized by the mixed interpolation functions. Within each triangular element, velocities were approximated with a quadratic function and the pressure was represented with a linear function. The non-linear system of equations resulting from the discretization process were solved by Gaussian elimination and iteration procedures. As a result, several routes to humping in viscous couplings are documented. The plate permeability associated with the perforations was found to have no significant effect on the humping scenario. The initial loss of symmetry can be provided by random fluctuations of the axial location of the inner plates, or by the presence of burrs. Once the symmetry is broken, the left side burrs at the leading edge of the inner plates can initiate humping with a preferred direction of motion toward the burrs side of the inner plate. It was found that viscous coupling have an ability to recover from the plate torsion. The fluid properties of the silicone oil are also associated with the humping. After examining the power law model, the visco-pseudoplastic model and the temperature-dependent viscosity model for the variable viscosity, it was found that only visco-pseudoplastic model and the temperature-dependent viscosity model can be used to explain the humping. For some transition shear rate (233.3</bar Str<816.5) in the visco- pseudoplastic model, the axial forces will increase the given asymmetry and initiate the humping. For the temperature-dependent viscosity model, the axial force initially stabilized the inner plate, after passing the transition time (0.028 sec), the axial force will destabilize the inner plate and initiate the humping.

Viscous coupling hump condition

Posted by albell in syncro, vanagon tech papers on April 2, 2010

I’m still curious as to how the viscous coupling goes into the hump state. My earlier posts with accompanying documents mention the hump state wherein 100% of torque is transferred from input to output shafts. Recall how the silicon fluid (some form of siloxane) thickens under shear stress and so begins to transfer torque. This shearing increases temperature and consequently pressure inside the coupling housing. VW’s own publicity literature states that the temperature rise is what causes the increase in fluid viscosity, but this research paper disproves that.

The problem I had was wondering what pushes the plates closer together to create the hump state. Just saying pressure increase does not cut it, for the coupling is in a sealed housing and pressure increase should be the same on both sides of the plates.

One thought I had was that there were localised asymmetric pressure increases, but I still had a problem with that as I thought pressure increases would be equalised quickly in a fluid.

Well I was half wrong, the following excerpt from a research paper by Mohan (2002) shows localised pressure increases forcing the plates together. Its a little like tilting your hand out the car window, or is it? Examine diagram closely and make up your own mind 🙂

Oh, STA, self induced torque amplification, is another term for the hump state.

So, as I see it, the progression goes like this:

-rotational difference between input and output shafts (ie front vs rear wheel speed difference, above the 5% or so allowed slippage) causes shear and increasing viscosity in the siloxane fluid.

– at some point, localised pressure differences between plates force the plates together, in effect coupling the input and output plates. Remember the plates are very close together, and one set is on a splined shaft and is free to move axially).

– then the standard story applies, when the plates are coupled there is no relative speed difference between the plates, the shear is gone, and the viscosity drops again, the plates separate and if the input and output speeds remain sufficiently different then the process repeats.

But one thing still puzzles me, in this paper (yes, same one referred to above)

vc-paper

the author notes the pressure increase inside the coupling during slippage, and wonders if some sort of pressure control on coupling could affect the hump state behaviour. I still haven’t resolved how overall internal pressure affects localised inter-plate pressure differences.

And to cap it all off, GKN Drivelines (heir to the Ferguson developers of the viscous coupling) published this bit of info:

See how the diagrams resemble Mohan’s diagrams above, But then they go on to say:

“The “Hump” mode is activated when the coupling achieves 100% filling due to fluid thermal expansion thereby amplifying a hydraulic throttling effect between the plates”

This statement is sort of misleading. Makes you think that the thermal expansion is general (which it is) and not localised (which it is too).

Oh and that reminds me, as you know the coupling is not filled 100% with fluid, there is a small amount of air left in (what is it, 7-12%?). This air ends up distributed, apparently, as small bubbles and acts as a moderating agent in how aggressively the coupling goes into the hump state. For instance, the less air left in, the more aggressive the coupling will be.

Call me an obsessed nerd if you will, but I wish the developers of the viscous coupling (Ferguson et al ?) would call me up and invite me over to explain all 🙂

Nice syncro

I found this series of pics on my computer. I don’t recall where I originally got them from, if anyone recognises them I’d appreciate getting the info for attribution.

Lots of nice touches, one thing especially is the raised instrument cluster which I think would allow a better view of the dials.

Syncro prop. shaft R&R

Posted by albell in syncro, syncro specific repairs on November 20, 2009

This last summer I replaced the original u-joints in the syncro prop. shaft. The previous owner had removed the shaft for the summer, but told me there was some drive line vibrations. There are a lots of tales of woe and intrigue on the net about prop. shaft vibrations, causes and cures, so I decided to have a go at fixing mine. First thing was to replace u-joints. Stock VW joints are expensive, so I used the same replacement joints as Herman did on his syncro project (Precision brand, part #813). The bronze bushings that the yoke assembly and shaft fits into at the guibo end of the shaft seemed ok, the shaft fit in snugly. I just re-greased that, installed the new joints (blanking off the grease nipple fitting holes – I couldn’t get a nipple to fit in the tight spot, you’ll see what I mean if you ever do this job), and then painted the shaft. I re-installed the shaft and still had drive line vibrations at around 50-60 kph. I tried the trick of loosening the front differential mounting bolts and driving the van to let the drive line “find its sweet spot”, but that did not work. I removed the prop. shaft and re-examined it, and noticed some play in one of the joints. I removed that play by installing a thicker circlip (new joints came with two sets of circlips, differing in thickness).

That seemed to have removed the play. I double checked the fit of the yoke shaft into the bronze bushing, was ok.

The next step is to make sure transmission output flange and front differential input shaft are aligned to specifications. They are supposed to be aligned longitudinally, but each flange can be pointing down slightly, 4 degrees or so. I have made a laser alignment tool and I need to get under van and do the deed. One thing that has slowed me down is my suspicion that my viscous coupling is weak, but that’s a story for another blog entry.

Meanwhile have a look at the old u-joints. Notice the pounded marks on one of the bearing surfaces! (apologies for the blurry pic).