Posts Tagged syncro

Trip – Camper Creek watershed again

My wife and I revisited the Camper Creek watershed that we went to a month ago. We had it in mind to see if we could find the trail down to Camper Creek, near the park boundary. So we set of on Thursday afternoon and arrived at our campsite around 3 pm. Funny thing about my stitched panoramas, the centre portion of the pic ends up narrower than it appears in real life. A bit of fog on Juan de Fuca strait, Neah Bay is over there on the other side, close to the middle of the picture and some smoke from (I think) slash burning up the hillside to the right of Neah Bay. Cap Flattery to the far right.

This fog evaporated as the afternoon wore on and we could see some of the marine traffic in the strait.

Neah Bay is behind the leftmost ship.

I’m guessing you get the idea that we didn’t do much once we got to the campsite, not much except sip cocktails, look out over the strait, and read mystery novels. Oh and then before you know it, it was dinner time.

And three Nighthawks appeared, diving and buzzing. Very hard to get a picture of them.

A bit of an apocalyptic sunset.

Next morning the fog was back.

I took us half the day to pry our selves out of the chairs and stop reading long enough to do some exploring. We found what we think is the trial down to Camper Creek, but the dogs were acting excited and we decided not to go down it for fear of running into something that the dogs would chase. There are lots of bears around this area, no shortage of bear poop, and our dogs have a history of going after them. So we decided to drive as far northwest as the logging roads would allow, heading to where Walbran/Carmanah Park “T’s” into Pacific Rim National park. It is a logged area between Cullite Creek to the north, and Sandstone Creek to the south. Interesting area but no great campsites so back we headed to the original spot. On the way back we had a dip in a nice pond in a gravel pit (often find blasted areas at the side of the roads. The rock used for logging road construction). I’d give this pit 4 out of 5 stars.

Back to the book. I was reading “Voices” by Arnaldur Indridason. The fog never did lift form the straits that day. We wondered about the number of fog days Neah Bay must have. Here is a link with some weather data. Seems that Neah Bay has at least 14 days per month of fog.

As the sun set, the fog crept up towards us.

But then the wind changed to a land breeze and the fog was pushed back a little.

Following morning was pretty darn nice.

We packed up around noon and headed back out towards Port Renfrew. We did explore some logging spurs, nothing much to report except to say that expect some bugs when going down dank, alder lined roads like this.

There was one productive side trip, up Braden main a few kilometres. A couple of female elk trotted across the road, finding and fumbling with camera got me this “Bigfoot spotted in PNW” class picture.

Then we found a nice spot where a bridge crosses Braden Creek.

We had a dip in the (cold) water then headed home. The van ran fine throughout the trip, but I’m really starting to get tired of the front springs – I still have the originals (tin top) on, and they are just not up to the task of supporting a westy conversion. I’d like a little more lift up front and I had been thinking about spring spacers, but now I’m wondering if those 2wd westy springs I have might be worth a try. I’ll need to look over the spring data again.

Vanagon – roof rack mounts

Posted by albell in syncro, vanagon, vanagon mods on August 5, 2012

A bit of a kludge, but I wanted to get some racks up on the van to carry my son’s kayaks and perhaps a Thule roof box. My old towers that I used when the van was a tin top would have been pretty tall on artificial rain gutters mounted to the pop top. We had another Thule rack, used on my wife’s Subaru and is one of those “sits on the roof and clamps to door frame” types. I decided to use it but swapping in the longer bars from the tall tower set.

Ok, to the scrap bin for this bent bit of 1/8″ stainless and away I went with the angle grinders.

I must have been hepped up on goofballs, this was the result for the rear most bracket (to be attached via pop top hinge bolts)

I drilled them for mounting and put them on. They looked, in a word, ass. Ok, back to the pile o’ metal and out with some 3/16″ (!) stainless flat. Cut, drill, grind, etc. and got something a little better. The first attempts were cut down to make the forward mounts and here are the results.

The racks are pretty firm, even with the forward pads not 100% in contact with roof.

Vanagon – syncro front spring removal without spring compressor

Posted by albell in syncro, syncro specific repairs, vanagon on July 19, 2012

The other day while replacing the upper control arm bushings on the van I wondered if the spring could be removed without using a spring compressor (Bentley shows compressor being used). I asked on the Yahoo syncro group and a couple of listmembers said it could be done, and they have done it. So today I had a go at it, and at the same time try out the spring spacer I made.

I have to warn you, while this procedure does not expose you to the same dangers as using a compressor , there are dangers to life and limb. That might sound like hyperbole but it isn’t. Please take care if you do what I am about to describe, take it slow, think, be cautious.

Also, what will be described was done on a van with stock springs and with a modest spring spacer. I do not think that it will work with longer springs or thick spacers.

Ok, on with the show. Van jacked up and supported by some solid 8X8 shorts, wheel off, sway bar drop link disconnected, radius rod/arm removed (inner adjusting nut not moved). The lower shock bolt loosened (22 mm socket).

Upper ball joint disconnected, those 2 socket cap bolts.

At this point I was not sure how this was all going to work, seemed like the spring perch would hit drive shaft.

Plastic cap removed from shock shaft end, 17 mm nut loosened but not removed.

Bottle jack supporting shock through hole in lower control arm.

Shock bolt was driven out easily.

And look at how clean that bolt is. I’m lucky, while I have some nasty rust on body, most if not all of the “mechanicals” are in great shape.

When the bolt was driven out and the bottle jack released, the lower control arm fell down. I did not expect this, of course in hindsight I should have.

The 17 mm nut was removed from top of shock and then shock and spring fell out.

Slight digression here, comparing the orange spring (2 white stripe code) from my ’82 diesel westy with the newly removed syncro spring. 20 mm difference between them. Confirms IG16 Wiki data.

And what do you know? The spring pads are different after all. Same part number (although writing this now I recall the syncro spring pad part number has an “A” suffix).

Shock fully extended with syncro spring.

Shock fully extended with orange spring. I would say a shock shaft extension would be need to use this spring in the syncro.

Side by side comparison.

I had to make some slight adjustment to the collar of my spring pad spacer to make it fit the syncro spring pad. Needed to reduce collar diameter a few millimetres

My T-handled tool in through access hole under seat to engage and guide shock shaft up through hole in shock tower.

The shock spring combo needed to be drawn inward to allow shock shaft to go up through hole in tower. I used a ratchet strap.

Here it comes, I’m using the bottle jack to push against the bottom of the shock. Lower shock bolt is installed.

You have to guide the shaft so that the step on the shaft does not get caught on edge of hole.

There you go, installed with spacer. You can see “shadow” line on spring pad that shows how much was in tower without the spacer. I did not re-attach sway bar or radius rod, but did put on wheel and drop van to ground. I bounced van as best I could and measured hub to fender distance. It looks like the spacer did the trick, now 19.25″ at front, 19.125″ at rear. Very preliminary measurement, probably will be a little different after driving.

So then I took it all apart again and removed spacer. I only have one spacer made, but the exercise was worthwhile – I can remove spring without a compressor and I refined my spacer to fit right.

And a bonus, I think I found my pesky squeak – it might be the bushing between sway bar drop link and the sway bar. I had made my own bushings from polyurethane skate board wheels, I greased them during this work and now squeak is gone.

Vanagon – syncro front spring pad

Posted by albell in syncro, vanagon, vanagon mods on July 17, 2012

I think I mentioned in my post about upper control arm bushings that I was considering further tomfoolery with the front suspension. What I have in mind is a modest front ride height increase – 1″ at the most – to compensate for the weight that the camperisation added to the original tin top. Currently I have approx. 19″ from wheel centre to fender edge on the rear (one extra stock spacer above rear spring) and 18″ from wheel centre to fender at the front. You probably know all the approaches to ride height adjustment, and no doubt have your preferences. I’m going to have a go making some spring pad spacers, similar (but not identical to) what Futbus in the UK sells.

I discovered that the spring pad is the same for both 2WD and syncro, so I could make a spacer to fit the 2WD stuff I have on hand. Here is the spring pad, underside that fits onto end of spring. Yup, that orange paint is there again. BTW, the spring (from ’82 westy diesel) had 2 white paint marks in middle of coils. The closest match I have found is the 2 beige mark one listed on the IG16 Wiki page about springs here. Do you get the idea that I am tempted to try these spring out on my syncro despite the 20 mm or so longer length? I am, but I want to have springs side by side on bench to confirm length differences. IG16 chart says it’s 20 mm diff, and that would translate to a 33 mm ride height increase (all things equal, ie spring rate). That is a tad more than I am shooting for, but so close as to worth trying.

Oh BTW, “x” amount of lift at spring translates to approx. 1.66 “x” at wheel. Slightly different multiplier at rear. The IG16 Wiki explains more.

You can see how the spring fits into spacer and the remnants of the tape that holds spring to spacer during installation.

So back to the additional spacer idea. I had this doughnut shaped bit of aluminium, was going to make some other goofy thing out of it, but never did.

I wish it was thicker stock so that I could have had a longer collar.

As is, I made the spacer 16.75 mm thick, and the collar 8 mm. The stock was originally nominal 1″ thick. I made a little bit of an effort to radius the top corner to mimic the stock rubber pad.

And the rubber pad pushed onto the collar of the aluminium spacer. This pic could be a little confusing, there is an aluminium disc under the spacer, more salvaged scrap.

Whoa! There’s that orange spring.

Pad and spacer on spring.

I probably will use some adhesive between the pad and the spacer. Seeing as I am just trying to bring ride height back close to stock tin top specs, I don’t think I will need to extend the shock shaft at threaded end. More on this to come later.

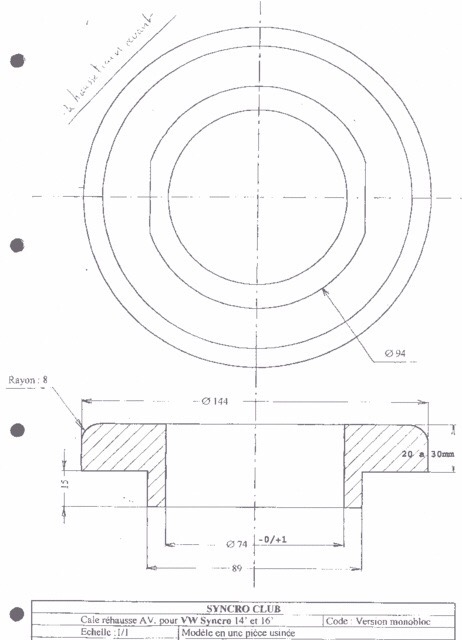

Addendum may 2017

Here is drawing I found in my files for Beau, pretty close to my estimates I mentioned in comments. Thickeness can be altered to suit of course. Don’t forget the multiplier effect of shim to effective lift.

Vanagon – syncro – VW tool 3141 substitute

Posted by albell in syncro, syncro specific repairs, vanagon on July 17, 2012

As I am planning on fiddling around with my syncro’s front springs and shocks I thought I might need a tool to guide the top of the shock back into position when re-installing. Bentley calls for VW tool 3141, the best pic I could find with a quick search is this Snap-On one. I had some 1/2″ diameter aluminium rod handy, and a M10 X 1.00 tap (same thread as used in pressure sender on engine, I needed one to make my sender relocation manifold). The lathe made making the tool easy, shaft is a press fit into handle and is pretty secure, but I probably still need to blob on a bit of weld on the joint.

End of shaft.

End of old 2WD front shock – it has the same thread.

Tool screwed onto end of shock.

I hope to be able to show you how it is used when I pull the front springs from the van, but I need to borrow a spring compressor before I get going with that.

Vanagon – syncro upper control arm bushing replacement

Posted by albell in syncro, syncro specific repairs, vanagon on July 15, 2012

So on our last trip I noticed a squeaking when suspension moved, noise coming from front driver’s side. I suspected upper control arm bushing so I set about replacing them on that side. It is a pretty straight forward job, and here are a couple of diagrams illustrating where the bushings are.

I jacked up and supported driver’s side front of van and removed wheel. When I detached the upper ball joint I could move the control arm by hand, and the squeak was there. 19 mm nut on one end of camber adjusting bolt, other end is 14 mm socket. Arm off and in the workshop.

Close up of one bushing.

Other side of bushing. There is a good chance these are originals.

Here is one of the new bushings. Vaico brand, I don’t know where they fall in the quality line up, but I got them in trade for some used vanagon parts. There is a great Samba thread on UCA bushings here.

I wondered if an O-ring would help keep any grease in.

Then I tried some silicone over the O-ring, a variation of what Tencentlife did in above mentioned Samba thread. I ended up removing the silicone and adding a second O-ring.

Now getting the old bushings out. I don’t have a press so I used a bit of aluminium tubing, a biggish socket, and an old 2WD control arm bolt, and a heavy hammer to drive the bushing out.

Look at that clutter. Workshop is in a real sorry state.

Old bushing out.

Bore of UCA where bushing fits. On the syncro it is a simple press fit, no spot weld needed.

Using a vice to press new bushing in.

Part way in. Ok, you’ve noticed that I painted the UCA. A very casual crap job and wasn’t needed (original paint still good), but I had a can of orange paint and I thought it might look cool. Overnight drying time was not enough, paint still soft, came off here and there. Perhaps I should lock up the paint.

A bit of pop can in UCA to keep a large socket in place while bushing driven home.

And the other bushing pressed in.

Out at the van, rear of support where bolt goes through and eccentric washer sits.

Front of support.

Rear eccentric washer in place. It was a fiddly job offering up the UCA into correct position and not have the washers fall out.

But in it went finally. Everything re-assembled. Guess what? I still have a squeak!

Next post will deal with camber adjustment and perhaps finding the squeak.

Trip – Camper Creek watershed

Just back from a couple of days exploring the area NW of Port Renfrew. My wife and I made a trip there back in May but bad weather limited how much exploration we did. This time it looked like our summer had finally arrived so we headed out there to see what was what. Turned out the gate on Grierson main was locked so we could not make it up to the nice view point we camped at back in May, so we headed west on Camper main and found a spot just on the southern edge of Walbran Provincial Park. Yup, another campsite on a logged off area – we joked about writing a book “Slash Camping on Southern Vancouver Island”.

But the view was magnificent, looking over the logged area of Camper Creek watershed, to the south and west the virgin forest of Pacific Rim National Park (West Coast Trail), and Juan de Fuca Strait and Washington to the far south. This panorama doesn’t show the park boundaries, but just to orient you, Port Renfrew is pretty well behind that dip on the left.

I’m not going to go on and on trying to defend our habit of camping on logging spurs, we’re just different, ok?

A bit of haze was coming in over the straits as the sun set.

Next morning, thick marine cloud had arrived.

We packed up and headed down the slope and further west, exploring spurs and dead ends. All the way to the Pacific Rim National Park boundary. On the way we found another logged view point. You almost can see our first night spot back up on the ridge to the left, middle of pic, narrow vertical grey logged area.

About 950 metres further west is the National Park boundary, it is logged right up to it.

I don’t know why I take pictures of giant stumps without some object in frame to give an idea of size, but I do. This cedar stump really is bigger than you think.

Had a look at Sandstone creek.

And then back up to to the previously scouted campsite.

It really wasn’t that bad. See the cloud still on the deck in the background?

The low cloud made the sunset quite spectacular.

The cloud started to form around us after the sun went down.

And in the morning, we got the cloud full on. Damp and chilly.

On our way back home, we stopped at a spot on the Gordon River, a few km upstream of the marina.

All in all a pretty good trip. No one got hurt, no van problems, no run ins with bears (plenty of bear poop around), and plenty of food and drink. What more can you ask for?

Addendum: some more pics from trip.

We often came across signs of cedar shake block cutting, folk salvaging something from left over wood. On this trip it was all Red Cedar, on our previous trip in the area we saw Yellow Cedar shake block cutting too.

Apart from locked gates (mostly to restrict access to active logging areas – protecting machinery), many roads are “decommissioned”. Can take the form of large ditches and gravel berms across road, or taking out bridges. The latter shown in this pic, and a tree across the road to stop folk before they go over the edge.

My quick and dirty levelling ramps worked fine.

One of our two dogs looking noble. We don’t usually have any problems with them and the local wildlife but they have chased off a bear on another trip.

And here he is, dog tired.

As I mentioned before, lots of bear poop around. I think the bears are feeding on Salmon Berries.

Another shot of the marine cloud and West Coast Trail boundary. Where I took the pic the temperature was in the mid to upper 20’s C. Next day when we were in the cloud it was around 14 C. We were sympathetic for the hikers on the trail, they probably had no idea it was so nice and warm 150 metres higher.

Not the biggest slugs in the world, but pretty big.

Some of the sandstone outcrops.

Vanagon – another use for scrap aluminium

Posted by albell in syncro, vanagon, vanagon mods on June 25, 2012

This time a bit of aluminium grating and it couldn’t have been easier to make – I cut it into two sections. Looks like it might work out in the field using rocks or wood to raise one end. BTW, my transmission bash plate seems to have generated a lot of chatter about increased transmission temps due to reduced air flow over the transmission. As with most internet chatter, no data given to support opinions but I hope to be able to do some temp measurements using IR gun (yes Simon, I’m going to ask to borrow it).

Vanagon – syncro bash plate project finished

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on June 24, 2012

Well the transmission protection part anyway. I decided to leave the plate mostly rectangular, but I did have to curve the front corners for no other reason than I thought it looked better. I also drilled some drain holes at the rear of the plate. Instead of using the drill press, I used the wrist buster, aka Van Dorn drill.

I made rather ugly holes with it, but I rationalized that (and other goofs) with the “it’s only a skid plate” mantra. I cut out slots for the stock skid bars and bent up the leading edges slightly. You can’t bend up that middle section too much or it will hit the nose cone of the transmission. I also gave the bottom of the plate some DA love.

I found it a real pain in the arse installing the stock skid bars by myself, but installed they were. See how exposed the transmission appears? Like having your goolies hanging out.

And same view with the plate installed.

Front view.

I think the extra width will help protect the inner cv joints and the fuel pump. Note to Simon, will also protect the speed sensor and that big electrical plug on driver’s side. But not sure about fitment around exhaust on your 2.5 Subie.

Next job will be to add some 1/4″ aluminium plate between the propshaft protection bars, and perhaps to extend that protection out sideways and attach to frame rails. That will help protect shift linkage and coolant hoses.

Damn. just occurred to me, forgot to paint the stock skid rails where I ground off the paint for welding the tabs on. I guess the project is not quite finished.

Vanagon – syncro bash plates project

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on June 22, 2012

I left the entire syncro drivetrain protection bars off my van after the propshaft business with a mind to installing some bash plates. The transmission is left pretty well fully exposed in the stock set up, and today I started doing a bash plate in that region. I had some scrap yard sourced 5/16″ aluminum plate to use.

Here are the stock skid bars/rails, transmission end. See the added tabs?

I had my first go at TIG welding…I still have a long way to go.

A real welder (good friend Dave) did the stainless to plain steel weld (609 rod).

Pretty heavy gauge aluminum, but it was cheap.

I match drilled and countersunk holes in the plate to match the nuts on the rails. The tabs with nuts were not located with any special measurement in mind.

Other side view. I’ll offer the assembly up to the van and see how much of the plate I’ll cut away. Rough sketches on plate sort indicates my thinking, “wings” towards the rear to provide a little protection to the inboard cv joints.

Project finished, blog post here.

Vanagon – radiator replacement (mine)

Posted by albell in syncro, syncro specific repairs, vanagon on June 21, 2012

Not really much to add to the previous rad replacement expect that it is my van (’86 syncro) and I thought I’d make it a post just for my documentation/memory aid purposes. I suspected my rad needed replacement for no other reasons than I think it is the original rad and that I noticed the rad fan coming on more often when idling after a hwy drive. The replacement is a Behr unit, made in South Africa. The old rad still had the a/c condensor rad attached in front, probably not helping heat escapement. The new rad did feel lighter than the old one, whether this is due to deposits in old rad or construction details I can’t say. No real details to note except that it is a pretty easy job. I clamped off the coolant lines so a total coolant replacement was not done, I glued on the little rubber washers on the spikes on top and bottom of the rad (so that they didn’t fall off during installation, and I sprayed Fluid Film on exposed fasteners in the general area. After install and bleeding, I have only idled van long enough (took 20 minutes) to get first stage of fan to come on, no road test yet.

Vanagon – that transmission noise fixed?

Posted by albell in syncro, syncro specific repairs, vanagon on June 7, 2012

I’m just back from test drive after installing my re-bushed propshaft and I can report that the noise I was hearing, and that I had thought was transmission noise, has gone! I’m chuffed!

But to ward off the Evil Eye, I’ll not claim victory.

Vanagon – making new syncro propshaft internal bushings – Part 2

Posted by albell in syncro, syncro specific repairs, vanagon on June 6, 2012

I decided to make a split bushing for the internal location. I first turned down some Delrin to final inner diameter (23 mm to match the turned down yoke shaft), then mounted it on a mandrel to turn down OD to 28 mm (was OD of upper bushing and I guessed that the inner one was the same).

I kept the bushing on the mandrel and clamped it in my wee milling head. I also used a small C-clamp on the bushing to stop it from popping off during slot cutting. I used a 1/8″ end mill to cut the slot, made the slot 6.8 mm wide (chord length) which I estimated to be slightly more than needed.

Finished split bushing.

And as I tried to install it, I realized I had no way of holding it compressed to get into the narrow bore, no grip after it goes into outer bushing area. Oh, btw, this is how the bushing should appear when it is finally in place at the bottom of the housing.

I had an idea, some stainless shim stock to act like a funnel.

That worked and I was able to tap the bushing home. You can make it out, down at the bottom.

The yoke shaft would not fit in, I had to chamfer the end of the shaft a little more, and polish the end. But I finally was able to tap the shaft in and it is nice and snug. Quite snug actually, it takes about 20 Nm to rotate the yoke, but no radial movement at all. Oh and another thing, I removed that flange on the upper bushing, didn’t make any sense. I’m feeling quite chuffed in managing to get some sort of bushing replacement made. I hope they will wear well.

Vanagon – transmission noise hunt

Posted by albell in syncro, syncro specific repairs on June 1, 2012

For the last couple of months I have been noticing a slight whine/howl when driving no load/coasting, in 3rd/4th or neutral, clutch in or out. Only in a narrow speed band, 50 – 60 kph. I’ve discounted rear wheel bearings and I resolved myself to having trans. taken apart and examined. So I started the pull process, first with skid bars and propshaft. After they were out I decided to drive van and surprisingly the noise was gone. So what does this mean? Maybe front diff is making the noise or is the removal of propshaft affecting whatever is noisy in transmission?

I pulled the front diff and took the case apart, 3 sections. Front cover and rear section. Mid section has R&P and I set that up to measure lash on the R&P.

Rear section removed (note spacer not on top of VC, I took it off before pic, sorry)

Front cover removed (cover was cleaned before shot).

I clamped the input shaft so it wouldn’t move.

And then set up dial indicator on outer part of ring gear tooth.

Close up.

I wiggled ring gear back and forth and measured lash. Was in spec (0.004 – 0.010″).

And teeth looked ok. Mind you Daryl at AA Transaxle says ring teeth don’t usually show wear, its the pinion teeth that do. Hard to really see them when in case.

During removal I had to cut the vent line as I forgot to remove banjo bolt securing it to case (did same thing last time I removed diff, doh). So I made up a nipple and added a section of vinyl tubing.

So where does that leave me? Daryl is suggesting it is the pinion bearing in the transmission and I can still drive it for a while. I’m not clear on how the propshaft affects that bearing but I don’t feel quite as pressured to tear into, or have a skilled person tear into the transmission.

Addendum: Dirk over on the IG16 forum, wondered if the ring gears did actually show unusual wear. He pointed to lines parallel to the teeth. I don’t think that these marks are anything to worry about.

Simon’s hightop – installed and off on a trip

Weekend before last, the hightop was installed on Simon’s ’91 syncro westy. Late night and quickly thrown together video of install.

And then this last weekend he took it on a trip.

Inside is insulated and carpeted, but side cupboards and little details still need to be installed.

Big difference from the start.

Overnighter NW of Port Renfrew

We grabbed the chance to do a little exploring on the south end of the island (Vancouver Island), specifically just northwest of Port Renfrew. The area you get to if you hang a left instead of a right after the high bridge over the Gordon River.

Typical, secondary and not heavily used logging road.

Further on, around 680 meters elevation, some old growth but mostly second growth (guessing old growth cut in the 60’s-70’s, perhaps later). Lots of Yellow Cedar, one down across road but a section at end cut and easily moved to get past (yes, patch of snow there).

And found a nice viewpoint to camp.

Olympic Peninsula (USA) in the distance, Cape Flattery on extreme right.

Like a bad haircut, or having a hightop on the van, the campsite was fine looking out, not so bucolic looking in. Still, no one around and plenty of firewood (felt like a millionaire burning Yellow Cedar, the scent is divine).

Tired dogs.

A couple of little lakes close by, here is a glimpse of one.

The clouds and rain moved in next day.

The “Excelsior” proved its worth at breakfast time.

Typical view when rain comes, looking north east.

We spent the wet day exploring the roads a little, but the low cloud made it a silly exercise. couldn’t see much. Headed back home via long loop up via Gordon River watershed and Cowichan valley (some pics of Gordon River area in this post). All in all a great little trip.

Oh, forgot to include one of those “same place, different time” shots. Side road on Gordon Main (TR4 I think), again on slash, where my son and I camped overnight while exploring region last year.

Then:

And now:

Addendum: I was asked about pressure cooker beside “The Excelsior”. It is my EKCO model I use winter camping and in the van, had it for 30+ years. I bought it second hand and it seems the model at least, dates from the ’40’s. Found an ad at this site.

Vanagon – eccentric stub axle?

Posted by albell in syncro, syncro specific repairs, vanagon on April 22, 2012

(note: holding stub axle by the splines was an error duly pointed out by David in the comments. Axle re-measured and post updated.)

I was complaining to Phil Z. about my wheel bearing failure and he suggested I have a look at the stub axle. So I chucked it up on the lathe, holding it by the splined outboard end (was careful to have the chuck jaws positioned correctly on the splines) and then I measured a couple of things.

Where the outboard bearing seats had 0.009″ runout.

At the inboard bearing seat I measured 0.015″ runout (sorry, fuzzy pic slipped past me).

Where the seal rides, 0.020″.

The face where the CV joint mates had 0.010″ runout.

I did not measure that outer edge of the CV mounting flange as I thought eccentricity there was not important as the cv is aligned by the bolts.

And here is a quick vid of the assembly spinning.

What does all this mean? How does a new stub axle measure up? Was this runout the cause of my bearing failure?

Addendum: Crow eating time. David’s points about where I was grabbing the axle (splines) was correct. I re-measured runout with axle held by outer bearing seat.

Runout at inner bearing about 0.005″.

At seal, 0.007″.

Flange face, 0.002″.

Looks a lot better in motion.

So there, no smoking gun after all.

Vanagon – cooling system leak

Posted by albell in syncro, syncro specific repairs, vanagon on April 20, 2012

Bloody vans eh? No sooner than I fixed that wheel bearing than another problem bites me. Last couple of days I had been noticing a slight whiff of coolant when I got out of the van. I couldn’t see any leaks, inside or out. Then yesterday I noticed that my coolant overflow tank was empty and even I could not ignore the fact that I had a real live leak somewhere. I topped up the tank and fretted about expensive repairs. Today after a short drive, the smell was much more pronounced and I did find the leak. Thank the Vanagon gods that it was a hose leak, short section that runs from the thermostat to the lower of the two crossover pipes at the front end of the engine.

This pic from above does not show any wetness (the bad hose is the lower, thick one). Update: I think it is this hose featured at Van Cafe.

But from below, you can see the marks of a leak.

I had to remove a bracket that holds the remnants of the Webasto coolant heater system to get at the short hose, and remove the bell housing vent to get it out of harm’s way (syncro bell housings are sealed to the motor and a vent is provided that leads up somewhere above the gas tank). No surprise I suppose when I broke the plastic elbow when removing the bracket, so it goes.

With the bracket out of the way, I could get at the hose. Off it came and time to look at it closely.

Just a pinhole really, but big enough to piss away 1 litre of coolant in about 30 minutes of driving. I had some used hose that I took the chance with, and I got it back in place. I had a closer look at the broken vent elbow, it was plugged solid with some sort of crap.

Then I made a jury rigged repair to the vent elbow using some silicone tubing, stainless tubing, and a bit of stainless wire wrap.

Yeah, I know, this hose leak is a not so gentle reminder that all of the cooling hoses on the van are old and tired. The thing is, I have it in mind to swap in a different motor so I’m being a bit cavalier with this old wasserboxer.

Vanagon – getting that 46 mm wheel nut off

It occurred to me that I should have mentioned how I removed the 46 mm castellated wheel nut off the rear wheel in the last post about the bearing failure. The nut is on there good and tight, Bentley says to torque it up to 360 ft lbs (for the 10 slot castellated nut, the older 6 slot nut was torqued to a lesser value, something like 285 ft lbs). I don’t have the heavy duty air tools that would handle this but I do have a 3/4″ drive, imperial socket that fits (1 13/16″ – handy metric to fractional imperial chart here), corresponding tommy bar, and a 3 ft section of thick walled steel pipe. You can apply a lot of twist with this set up and can even get a fairly good idea of torque applied if you know your weight and where about on the pipe you are applying it. You know the drill, 100 lbs of weight one foot from the axis of rotation is 100 ft lbs, same weight two feet out is 200 ft lbs. You loosen the nut before you jack up the van, and have the handbrake on. But the other day when I was doing the bearing job I had a dickens of a time getting the nut off without the wheel turning and the van moving, and it was impossible to loosen the nut on my parts van as the transmission is out and the free end of the axle was just hanging in space. I did try the slug wrench mentioned in my original post on wheel bearing replacement, but it did not budge the nut.

So how do you stop the wheel from turning when you are grunting down on the end of the 3 ft extension? Well, you have to jack van up and support it securely on good jackstands. Remove the wheel, and use the lug nuts to secure some sort of metal bar to the brake drum. I have lots of scrap bits of aluminium around, so I used some 1/8″ 3/16″ thick angle. The angle bears on the ground stopping the hub from turning. Here is a snap taken today when I pulled the drum and hub off the other rear wheel to have a look at the brakes. Not very clear in the pic, but there are 2 lug nuts holding the angle to the drum. Note also the old house jack supporting the socket extension.

This really worked, no drama, no movement of the van. Used the same technique when tightening the nut.

Oh and here is what I wanted to look at. With the hub out of the way I could see the gubbins clearly and I wanted to be sure all the brake springs were installed correctly (I *think* they are). Plus I wanted to pull off the threaded adjustment bar and clean it up so that it would actually adjust (I hate the Vanagon rear brakes).

Vanagon – rear wheel bearing redux

Almost exactly a year back I replaced the bearings in right rear wheel, but a couple of days ago I noticed some play in that wheel. I thought more play than there should be (i.e. none to a teensy amount). So I pulled the bearing housing and this time taking the driveshaft and CV joints with it. That meant CV joint to transaxle connection detached. I had a spare assembly, all greased up and ready to go, was from my old ’82 westy and still ok.

Got it installed ok, never really a fun job. Then I had a look at the one year old rebuild. I had the notion that maybe the bearings might be loose in the bearing housings, but no, they had to be driven out with some effort. The outer bearing looked fine, but the inboard bearing looks discoloured.

And it feels slightly rough when spun. So what’s the story? Did I not lube it enough during install? This picture from then looks like I did not put much grease into the bearing, but what you see is the stuff I had smooshed into the bearing, more lube was put on after the bearing was in place.

Maybe I did screw up, wouldn’t be the first time.

Update: looking at the bearing again, I’m not so sure it overheated. It looks more like corrosion on the outside of the outer race. Still puzzling.

Addendum: I cleaned up the CV joints on the axle I removed and one joint is ok, the other is on its way out. I have to admit that I had not serviced the rear CVs since I bought this van a couple of years ago, it really should have been done. The grease was a bit dry on both joints, and one showed signs of impending failure (Ed. jeez, that sounds a bit over dramatic).

Outer race removed.

Expected and acceptable wear.

One of these balls is not like the other ones.

Inner race, would this erosion spread?

You kinda wonder if tri-annual repacking of CV joints is the way to go, or just replace them every seven years or so. It is a bit of a chore getting the axles off, and more of a chore cleaning and repacking. CV joints are about 90 bucks a piece here, I don’t know what is the best strategy.

Simon’s hightop painted

Posted by albell in syncro, vanagon mods on March 17, 2012

Vanagon – VW pop top insulation

Posted by albell in syncro, vanagon, vanagon mods on February 13, 2012

Borrowed from good friend Simon, this genuine accessory is supposed to be installed outside the pop top but with the rain fly on, I thought I’d see if it was able to be installed inside. A little bit of a wrestling match, but it goes in and stands up by itself. Hey, notice I still haven’t installed an upper bunk.

Vanagon – Go-Westy “Wasserstopper” rain fly

Posted by albell in syncro, vanagon, vanagon mods on February 13, 2012

Note: clip fitment issue resolved, see this post

A Xmas gift installed. Over all pretty good but I don’t like the side clips that are supposed to hook on to the rain gutters. They have a too tight curve and don’t grip well. Also, the strap that goes in the front doors and hold the front of the fly down tight to the van is not that great of a method. I’ll try modifying both. However, as is, the clips do attach to the Shady Boy awning box. No way to get them to attach to the gutter with the awning box in the way. Link to Go Westy product page here.

Vanagon – Small Car stainless header failure

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on February 12, 2012

Was installed new about a year ago, in a EJ25 powered syncro. I suppose disappointing would be one way to describe it.

Vanagon – wiper shaft lubrication

Seems like a slim subject for a post, but perhaps some of you don’t know it can be done. The shafts that stick out of the front of the van, and to which the wiper arms are attached, have a plain bearing sleeve. I bet that over time any lubrication in the sleeve is lost and the shaft gets that little bit harder to move.

I have a spare wiper assembly in the barn, so here are some pics of the shaft and housing.

Front view, showing the splined area that the arm meshes with, the threaded end for the wiper arm securing nut, the threaded base that the big nut that holds the housing in place on the sheet metal (the housing is also held to the van by phillips headed screws that you can see at the front edge of dash board near windscreen). You might be able to make out a circlip just above the large threads.

Circlip removed, 2 washers, and a rubber grease seal.

Back, inside view of above, circlip and washers removed and the shaft pushed back. This exposed shaft is what need lubed.

Make sense? Ok, out to the van. First pry off the plastic cap at the base of the wiper arm. See the little slot on wiper arm base where you can insert a screwdriver to twist off the cap?

Cap off, 10 mm nut exposed. Often it is pretty rusty in here.

Remove nut and thin washer, wiggle wiper arm and remove from stud. The splines will look cruddy like this one, no worry, clean the splines out with a pin/needle. It’s these splines which bite into the softer metal of the wiper arm that prevents the wiper arm from slipping, not how tight the 10 mm nut is. So spend some time to clean the splines out.

Pry off the black plastic shroud. Careful, don’t scratch the paint.

That big nut is supposed to be somewhat tight, 69 in. lbs (8 Nm). You can see the golden coloured circlip, remove that (don’t lose it!).

In this pic the circlip and the 2 washers have been removed, and the 10 mm nut put back on the shaft (to give me something to hold on to). The shaft was pushed in and out a little and that made the grease seal pop out.

Bentley says to use molybdenum disulphide grease on the shaft, I used gear oil. If I had the shafts right apart then grease would make sense, but seems to me that oil is better in this situation.

And then it is just a matter of putting it all back together. The circlip might be the hardest part to re-install. The wiper arm nut is tightened to 5 Nm (43 in. lbs). Do not over-tighten, risk of strippage! I place the arm on the shaft and before tightening the nut, I move the arm into proper resting position Then tighten the nut and the assembly draws up without moving out of position. Oh, and another thing, I glob some waterproof grease onto that nut to reduce rusting.

Vanagon – front door check strap

A few months ago my driver’s side door was allowed to swing open hard (van parked on hill, happened on this trip) and the check strap snapped. Got around to fixing it today. I had a spare assembly from my ’82, straightforward swap.

After the door card is removed, you can see the check strap assembly inside the door. The ’86 has a plastic cover over the works, the old ’82 did not.

Cover removed, two phillips head screws holds the mechanism on.

Removed and the broken end on the other side. The remainder of the strap, the part attached to the door jamb and held on with a pin and circlip arrangement was removed when I snapped the strap.

The replacement unit, and the waterproof grease I’ve been using recently for this and that. The stuff really does seem to resist washout better than regular grease (ie on shift linkage)

Installation is simple, no gotchas, here is pin on body end of strap.

Addendum: In the comment Jon asked if the check strap could be adjusted to give more resistance. I can’t see how that could be done, perhaps Jon’s mechanism is broken? Here are more pics of the “resisting elements”, the hard faced rubber bits that pinch the steel strap.

Vanagon – syncro front diff. input seal replacement

Posted by albell in syncro, syncro specific repairs, vanagon on January 13, 2012

Back in October last year, when I had the front diff. out to install a new VC, I noticed that the input seal was leaking. It would have been smart to replace it then, but I couldn’t wait for the seal to be ordered in. Then I procrastinated, put the job off until today. The job is quite straightforward; disconnnect the prop shaft from the front diff., undo the 24 mm nut that holds the drive flange on the input shaft, remove flange, remove seal, replace seal, replace flange, etc.

Addendum: Have a look at this thread on Yahoo Syncro list for discussion on cheaper seal. I didn’t see that thread before I bought the expensive one from dealer.

I’ll be pedantic and list the steps I took:

– chock pass. side wheels and jack and support driver’s side so that left rear wheel is off ground (you could have both wheels that side off the ground, would be easier to rotate propshaft to get at all the propshaft flange bolts)

– loosen the 3 bolts (17 mm) on the rubber mounts on front diff.

– mark the propshaft flange, the front diff. flange, and the front diff so that you can get all the bits back in same orientation.

– remove the 4 nuts and bolts holding propshaft to front diff. flange (13mm, use 2 open end wrenches), and let the propshaft rest on ground, or support with wire.

– rig up some sort of tool to hold the flange as you undo the nut (24 mm), the nut is on there tight (135 ftlb). My elegantly engineered (ha!) flange holding tool required the pass. side propshaft protection rail to be lowered a tad.

– a 2 arm puller to pull the flange off the shaft, came off very easily.

– the exposed seal can be pried out with a strong screwdriver. I was surprised at how secure it was in there. Be careful not to damage the aluminum housing.

– some oil will drip out, have a container in place to catch it

– new seal is lubed then, as the Brits say, offered up to the housing. I used a brake caliper piston to carefully drive the seal home.

– then the flange, and the washer and nut. Again you need to hold the flange as you tighten the nut.

– propshaft back up and secured.

– some gear oil squirted in the fill hole (17 mm socket head plug) just back of the driver’s side inboard cv joint.

– the diff mount bolts left loose for a few miles, then tightened up. Just to allow the front diff to settle in a happy place (a sort of horizontal self alignment).

Addendum: overview of area. 26 = 24 mm nut, 25 = thick washer, 24 = input flange, 23 = seal (22 = circlip and 20 = bearing. Both un-involved with this repair)

Here are some pics:

See the oil splash?

Propshaft removed, the 24 mm nut that holds the input flange on is revealed.

Flange held firm using homemade tool, nut loosened.

Flange off, seal exposed.

Shots of how the brake caliper piston is a good fit to use as seal seating tool.

New seal installed.

Vanagon – syncro viscous coupling anatomy – part 2a

Some more images of the slots on the slotted plates of the VC. Any burr or ridge is not so clear, but perhaps there is one on the worn side of the plate. The series show the same plate, un-worn, then worn side. Clicking on the pics will bring up larger version.

Un-worn side.

Worn side.

Un-worn side.

Worn side.

Vanagon – syncro viscous coupling anatomy – part 2

I took some pics (btw, all the pics can be clicked on to get larger image) of the plates in an attempt to see those “burrs” on the holes or slots that are implicated in the hump or STA (self torque amplification) event. I think having my sketch diagram of how the plates and spacers are arranged would be useful here:

Here is the stack as it comes out of the VC. Note that the circlip and shims are not on the end of the shaft. Also note that the top plate is not held in the stack by the circlip, but rather is pressed against the endplate when installed.

The reverse side of that top plate, obviously worn.

And the slotted plate below.

Now remember, these two top plates are not spaced apart. The next plate however, is spaced from the slotted plate you see by approx. 0.025″. Mis-focused on this pic, but included it to keep the arrangement clear. See the wear on it even though it is spaced from the plate above?

Here, with the above plate beside, slotted plate turned over.

Closer view.

Here are the adjacent surfaces of another pair, same arrangement as the worn pair above, ie has spacer separating them. Note that they are not worn.

Now lets get a better look at the punched holes.

Closer, I’d say there was a raised rim, very subtle.

And a shot of worn plate holes. I think you can see where the rim/burr whatever you want to call it has been worn.

I only had time to get one close up of the slots in the other plate type, no rim evident on this side at least.

Well, this exercise demonstrated, to me at least, that there are burrs on the punched holes. As to the role of these burrs, I will deal with that in part 3.

Vanagon – syncro viscous coupling anatomy – part 1

Posted by albell in syncro, syncro specific repairs, vanagon on November 21, 2011

This post is just to clarify, a little, how the plates inside a viscous coupling (VC) are arranged. My post on replacing a VC shows more pictures of the assembly and the seals.

Maybe a couple of pics of the VC (end plate removed) to set the scene. Note the end shims, and the absence of the circlip (groove for it in shaft is visible) that keeps the plates all together.

Another angle, end shims removed.

There are 24 pairs of plates in the VC. One set are keyed to drive (or be driven by, semantics) the VC housing itself. So these plates have notches around the edge that fit in internal splines on the VC housing. They also are the plates with the circular holes in them. The other set of plates, slightly smaller in diameter, are keyed to drive the central splined shaft. They have slots in them. The propshaft from the transmission is connected to the housing, the pinion of the front differential is connected to the central shaft of the VC. The silicone fluid filling the VC is what mediates the power transfer between the plates. I won’t be going into the silicone fluid in this post.

There are spacers between pairs of plates, and these spacers fit into the hole in the middle of the plate that is keyed to the housing. The spacer is (all measurements are approximate) 0.065″ thick. The plates themselves are 0.040″ thick. So with the spacer partially lying in the hole of one plate, it only projects about 0.025″. That means the plate pairs are separated from each other by 0.025″. I think it is time for a simple diagram.

Does that diagram make sense to you? You can make out the spaces between the plate pairs in this picture of the entire stack o’ plates out of the housing but still on the shaft.

Oops, looks like I left the last plate in the housing. Also the aluminium ring I am using to support the plates is causing the plates at the end to be pushed upwards. Of course when in the housing they are all aligned. Here is a closer view, no mistaking the pairing of the plates.

And here is a stack of 2 pairs, plus one shaft keyed plate on top.

I think I have established that the plates are in pairs 🙂

I’ll post pictures of the wear patterns on the plates and try and relate that to the pairing of the plates in the next part. All comments and corrections welcome.