Archive for category vanagon

Vanagon – another approach to wiper arm rivet

Short story, made a rivet from stainless rod. One end with shoulder, the other end with hole ( to make that end easier to flare).

Worked really well. But I think it’s unnecessary work. Both friend and I had the same idea of finding Chicago screws that will do the job. And those screws are out there.

Funny thing they are called M5 Chicago screws, but the actual screw portion is M3. Pictures show better. Oh and you’d have to trim the length a tad. Is brass hard wearing and strong enough? I think so.

Back to my rivet. Here’s a sequence of pics using another old wiper arm. First couple show how you can hold the “c” connector in a vise and pull back on the arm to release hub. Head of the stock rivet drilled out and punched thru. Stock rivet 50 microns larger diameter than the Chicago screw… yadda yadda yadda…you get the idea.

Vanagon – trying out a wiper hinge rivet sub.

A few posts ago I wrote how I took apart my spare wiper arms for powdercoat. The hinge between the arm and the hub was a steel rivet, had to drill that out. So what to do about reassembly?

Tried something this afternoon. Yeah, perhaps an over thought idea. Turned down some stainless rod to around 4.8mm, with a poofteenth narrower shoulder on each end ( the arm holes are smaller than the hub hole. Maybe it’s the paint.)

Tapped each end M3. I have some plastic pan head M3 machine screws, I’ll get some black stainless versions if I decide this is a good method. What gives me pause is I have to bend the wings of the arm apart to get the shouldered hinge pin, in the hub, inserted into arm. It’s kludgey.

But looks ok, arm moves nicely too.

Vanagon – conversion table for VW tool 1301

I found this table online and I apologize for forgetting where, I’d like to be able to credit the source. I think there have been posts on the Samba with the same info.

In any case, the VW is used in Bentley procedures to test fuel and temp gauges.

David B. commented:

The Vanagon gauges are electrically the same except for the blinker circuit in the temp gauge.

Gauge resistance ~52R, input voltage ten volts plus/minus a half for tolerance of +/- half a needle width.

Top mark ~35R (fuel full or temp ~130C)

Temp blinker starts ~45R (~125C)

100C touching high side of LED ~82R (OE sender)

90C touching low side of LED ~106R (OE sender)

Top of reserve ~170R (adopted in later models as the calibration low point instead of bottom of the gauge)

60C/empty/bottom mark on gauge ~265R

Vanagon – quick fix, arm rest bolt caps

Originals were a bit ratty, and a couple wouldn’t stay put. Made a set from black Delrin. You 3D printing folk have an advantage over us subtractive makers 🙂

Ok, bear with me, trying a link to the fusion 360 file, might take a few tries. Grrr, trying to insert model into a frame here, dint have the skill. This link though will take you to model and I think you can download.

Hold on, managed to have a zipped file of the fusion model, to download without going thru fusion’s meat grinder.

what a lot of palaver for such a inconsequential thing.

Vanagon – cheap wireless tire pressure monitor

You must have seen these around. All the usual suspects sell them and I went for one last summer.

Around 30 bucks, worth the gamble.

It has a wee solar panel and function buttons on top of it and a micro USB port on one side ( kit comes with short micro to standard usb cable). There is a sticky type gel pad on the bottom to keep it in place on your dash, and that works well.

The solar panel keeps the unit charged up, mostly, after an initial charge via USB. I say mostly as the panel couldn’t manage to eek out enough current during a one week period in December. Weather was very dull, days were short.

Buttons on top of unit for setting things up. You can have low and high pressure alarm limits, and low temp alarm. Alarm is beeping and display flashing. The display changes from off to on when it feels movement , ie when I open the drivers door to get in.

The pressure and temp senders replace the tire valve caps. There is an additional locking nut supplied for each sender thats supposed to hinder theft and loosening. Of the senders that is, not the van.

The senders connect to the base unit with no fuss, and I haven’t had any disconnects between the two. Each sender has a button cell powering it, I haven’t replaced any yet. I thought the senders stuck out from wheel more than I’d like, but I haven’t knocked one off yet.

For the first while I was obsessed by watching the pressure and temp during trips. I wanted to see if there were any temperature differences between front and rear wheels during braking on long descents. Maybe I saw a 5-10 degree difference sometimes, but as the senders are sticking out in the airstream I’d say it’s not a good way of monitoring brake temps, but you do find out which side of the parked van the sun is shining on 🙂

All in all I’m pretty pleased with it . It sits on the dash, drivers side corner, not too obtrusive and getting some light for the solar panel.

Vanagon – Syncro coolant distribution tower

Last summer my tower started to leak. Everyone knows the plastic distribution tower / manifold weakens with age. The 2 wd tower is different in size and shape but same thing happens to it.

What I posted to the vanagon mailing list:

A few months ago I swapped in an aluminum version of the stock plastic coolant distribution manifold. The 2wd and Syncro versions differ in shape but not in function.

I’d always wanted to do this but what got me off my duff was my manifold had the additional feature of a temp sensor plug in one end. This is for the optional webasto aux heater that warms the coolant and thus the heater box. It was fairly common on Canadian spec Syncro.

The temp sensor is very much like a temp II sensor in that it’s a push in device with an o ring and retaining clip.

The o ring on mine failed and leaked coolant. Temp fix was new o ring. The better fix was the aluminum manifold which was easier and less messy to install than I feared.

Bottom line is, if you have the webasto aux heater in the engine compartment of your Syncro, or if you had one and forgot about the temp sensor , check the sensor O ring.

Vanagon – parking brake cover, recover

Another example of idle hands. I think it was from model year 85 on where ther parking brake cover was changed from a vinyl boot thing to a hard plastic shield. And on my 86 Syncro it’s the brown plastic. The brown plastic that does not age gracefully. So one Saturday last summer I took some thin leather, got it a bit damp, and glued it to the plastic. It looks fine, some little wrinkles at the hard curves, but acceptable. Have not yet figured out how to cover the actual handle.

Vanagon – solar panel roof rack prototype

Still being worked on, as is, it’s fine. But front dam shape and side rail shape modified on the next version which is about to be powder coated black. Note that through complete luck, I can store one fiberglass bridging ladder up front. And disregard the clumsy fasteners used on front dam, that was just because… ran out of the correct ones.

Vanagon – Syncro, Steyr badge

More output from the devils tools. Aluminum, on good friend Simon’s Syncro.

Vanagon Syncro – Steyr sticker

Idle hands are the devil’s tools etc…

Vanagon – wiper length difference

Taking apart a pair of wiper arms and noticed for first time they are different overall lengths and different lengths between bends. 28 years of vanagon ownership and only now saw this, ha!

Update:

Close up of part numbers on arms. 251955409

Compare to the rear wiper, mirror image, not swappable.

Photo of South African T3, Same rear wiper orientation as left hand drive. Photo taken from the Samba. Oh btw, my rear wiper part number is 251955707.

Update February 13, 2020. Got the arms back from powdercoat. I had them blasted and painted with slight texture finish satin black. They look really good, pic doesn’t fully convey the nice finish.

Vanagon – LED headlight H4 bulbs, next chapter, Part 1

Posted by albell in vanagon, vanagon mods on October 17, 2017

Last winter I installed some LED H4 bulbs into my e-code lamps. Here is the link to the last update about them. If you haven’t read that post, and the original install post referred, and you want to know my reasoning behind trying the bulbs, I urge you to go read them.

Oh and another proviso, I bought both the original and these new versions from Banggood. They weren’t given to me. My opinions about the bulbs are not influenced by any freebies.

So why did I buy new bulbs? There are three reasons. First one is I was not happy about the radio interference they caused. The interference affected weaker fm stations. It was annoying. Secondly, I wasn’t satisfied about the high beam projection. The beam seemed to get lost at distance. On the other hand the low beams are so good that I didn’t need the high beams as often as I did with halogen bulbs. Again, please refer to the post linked above for more on beam patterns. The third reason for trying another set was that these bulbs come with optional gel filters, yellow. I was curious about how they would work.

Ok then, here are the new bulbs, and here is a link to the product page. Link fixed, sorry about that.

Similar to the older model ( on the right ) but with some important differences.

Right away you see the heat sink is different. I think that the older bulb has some electronics in the base, the new ones have a separate box of electronics. And notice the difference in the led element, size, number, and orientation.

I’m going out on a limb and say that the newer bulb has the LED elements arranged to more closely mimic the filament positions in a halogen H4 bulb. Interesting that the elements are smaller and fewer but the bulbs are advertised as 30W each compared to the 25W of the older bulb.

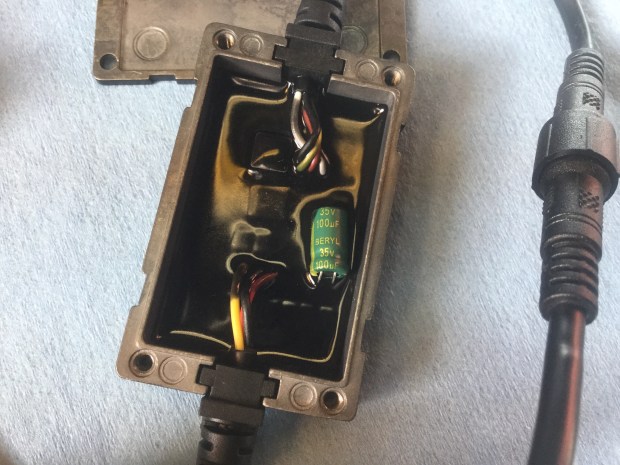

The new bulbs have a metal box in the power line. I was surprised it was metal, made me hopeful that the radio interference issue might be fixed. Popped the cover to have a look.

Components are potted, only a cap showing.

I was impressed, I started to think that these bulbs were surprisingly well made. The power line has a very positive and o-ring sealed connection. This probably eases some installs, makes no difference in the van.

The filters, according to the instructions, are self adhesive and applied to the glass tubes.

I’m holding off on the filters for now, but I did install the glass tubes. The end of the bulb unscrews and the tube slips down and seats against an o-ring.

O-ring wasn’t in correct position in that last pic, but here we go fixed.

Another interesting feature is the rotationally adjustable mount. The three tab base is held in place by two set screws, and it can be rotated. There is a degree ring on the base and a witness mark on the bulb body. I did not change the orientation, I’ll wait for some night testing to see if it’s needed. I’m only guessing right now about what effect the rotation would give.

Time to pop them into the lamps. The older bulbs thicker bulb body didn’t let me install those rubber boots, but the new ones did.

Here is new bulb without boot.

If you remove the three tab mounting base you can push on a boot and then reinstall the base. The boot is everted here, makes it easier to get at the set screws.

If you remove the three tab mounting base you can push on a boot and then reinstall the base. The boot is everted here, makes it easier to get at the set screws.

Keep the boot rolled back and carefully get the retaining wire bails clipped in.

Ok, so I actually installed one lamp last night. Right away I saw that the beam pattern on the garage wall was tighter, both low and especially high beam. The radio interference problem was still there, grrr.

But today, with both bulbs in, the interference problem has disappeared! Yes, that’s right, weak fm stations now back on the menu. I’m really chuffed about that.

Next to do is swap one of the old LED bulbs back in and do a comparison, take some pics etc. So far I’m really pretty impressed by the build quality of these bulbs, especially for Can$64.

Vanagon – alternator voltage regulator re-brushing

Posted by albell in vanagon, vanagon mods on October 1, 2017

During the summer, on a camping trip, the alternator failed. The brushes on the voltage reg finally wore out. I had a spare (used) voltage reg on board and the swap got us going again.

The failed regulator was an adjustable unit I bought way back in the early noughts. It got swapped over from my old 82 westy to the Syncro in 2011. It had been working perfectly all this time and I really liked the ability to up the voltage output a little to overcome any voltage losses in the wiring up to the battery and also to give my batteries a good charge.

I think the reg cost around 35 bucks back then, haven’t checked the prices these days. Might not seem cost effective to repair it, but I wanted to. Hey why not? What’s the point of other folk posting how to do it…

Local automotive electrics outfit, Brian Roberts, sold me a pair of brushes for 8 bucks. Just $8, a little solder, flux, and time, and the reg was fixed. I wasn’t very good at documenting the steps but here we go.

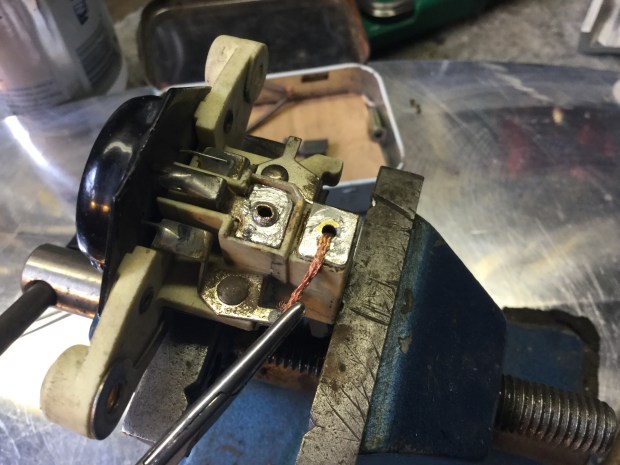

The new brushes look like this, carbon-like with a braided copper pigtail. The spring is the old one, no problem re-using.

To get the old brushes out, well originally, under the solder, the metal is formed into a tube which is crimped onto the pigtail, soldered, and trimmed.

I found that merely melting the solder didn’t release the pinched pigtail. So I drilled it out. That meant when I inserted the new brush and pigtail I had to hold the braided pigtail…

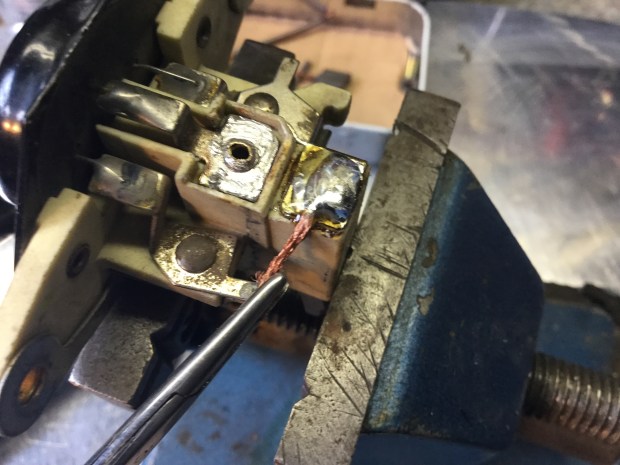

Pigtail with spring fed up into the brush holder on the reg, haemostat holding pigtail so brush projects fully but doesn’t come out. Then, flux (rosin) and a good strong iron.

Was hoping for a better blob, but it’s ok.

And the iron? This old Weller, it’s a champ with this sort of thing.

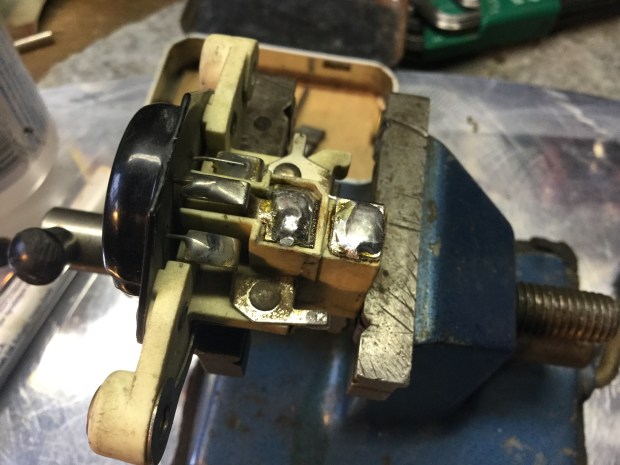

Same thing with other brush. Then trim the excess copper

So that’s all good. Hey just as an aside, clean up shiny, all the contacts on the reg and also on the alternator body.

Acesss to the lower machine screw holding the reg to the alternator is fussy in the stock wbx. An intake runner impedes screwdriver.

An offset screwdriver does the job, albeit slowly. But beware, if you didn’t disconnect the battery then you can hit the hot stud on the alternator with the driver. The angry pixies make you jump. Foiled a second attack with heat shrink on the driver. But the pixies managed to nibble one end, see?

Oh, btw, adjustment of the reg is done via little screw.

Dialed mine up to 14.65 V at alternator. But I’ve noticed that the voltage will drop maybe half a volt or so when the alternator heats up. Btw, the multimeter is pretty good for $15, banggood. Auto ranging, back light, big display, AA batteries rather than 9V. Still have the protective film on display, it’s not a thing with me, just forgot.

Vanagon – another Syncro in Graz

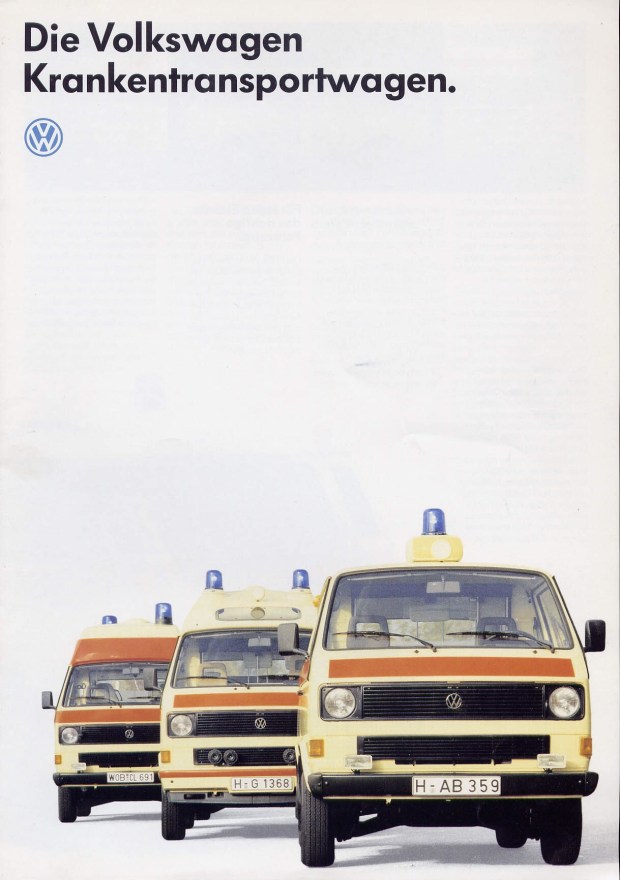

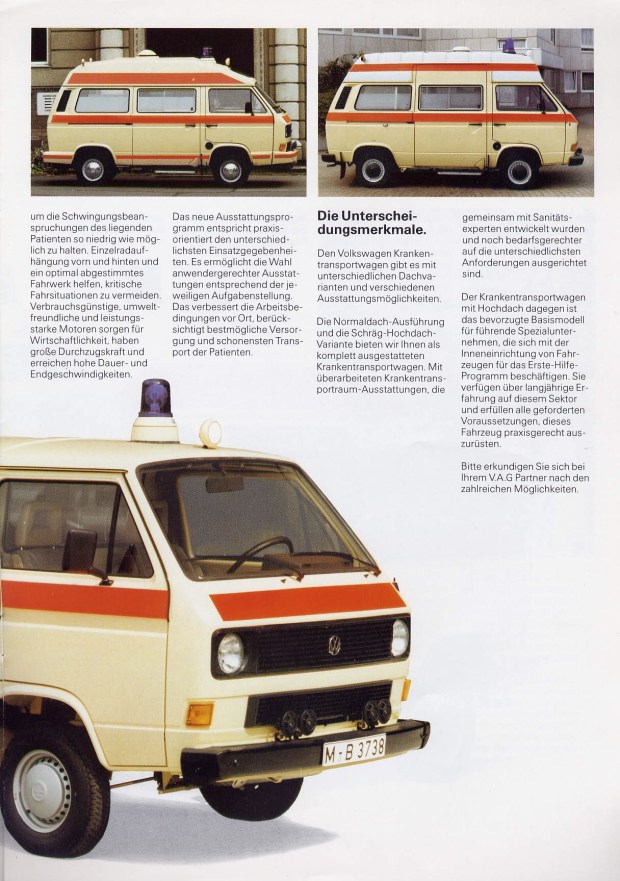

Simon is back in Graz and spotted this Syncro hightop. I haven’t seen this particular style of hightop before, it looks similar to others, but not quite. I’m thinking it might have been originally an ambulance, (but the roof is different than the factory hightop ambulance). In any case, it’s a nice looking van with interesting features. Side note, Simon says he’s seen few if any vanagon’s in Croatia with fancy wheel and tire combos. You know this hightop Syncro would be re-shod almost immediately if it came to North America.

Update:

Thanks to ZsZ in comments, found what looks like to be a match on vwpix.org. Link to the images here.

Here are a couple from that page.

Vanagon – more from Croatia

Simon hit a wrecker’s yard. And elsewhere found a hard working 2wd Doka.

LT first

Vanagon – my van and another van

The other van has 18″ rims, nice big brakes up front ( and they do have a great pedal feel ), Go Westy 2.4 wbx. And it has a list of repairs needed.

Vanagon – sightings from Dugi Otok

Vanagon – minor changes to old mods

Posted by albell in vanagon, vanagon mods on July 22, 2017

A while back I made an aluminum grill to replace the stock grill on the rear side of the kitchen unit. I made it such that it would house an USB dual outlet and a voltmeter. Later I rotated it so the outlets were in top.

It was ok, never did paint it. What bugged me was no switch to turn off the voltmeter and outlet. So with more enthusiasm than design skills I made another and this time added switches and painted. Btw I used krylon espresso brown which I was told was a good match for the brown in my older westy cabinetry. The pics don’t really show the colour well but it’s darker than stock.

That thing in the aluminum block is a digital controller I’m using for the fridge fin fan(s). More on that when I post my findings about my fridge mods. Yeah you can see a bit of sloppily applied insulation on the fridge exhaust pipe, that’s much less than originally installed. Again, more on that later.

Now I can switch on the volt meter and USB outlet. The thermo controller has its own on/off function. Extra switch thrown in there just in case.

I did make the vertical slots as long as I could, but I didn’t mean to slightly overlap the cabinet. Doh…

Also refined, ha, the “new style westy table on old style arm” mod, link and link, slimming the aluminum adapter down a tad and adding a plastic spacer, ( the red thing, don’t know what kind of plastic, might be Delrin).

Surprisingly, the plastic spacer improves the tightening action.

And back to that espresso brown paint. I painted the little indicator panel on the kitchen unit front face. Maybe you can see the colour mis match in this pic. Nothing quite like taking a picture of something to make you realize just how beat up a thing is, man, look at those dents etc. Oh and another thing, trying this and that to bring back some life to the rest of the face plate. Paint was chalky and faded.

Vanagon – spotted in Graz

Vanagon – that clunky airfoil roof rack update

Posted by albell in vanagon, vanagon mods on July 5, 2017

Last year I made a pretty clunky roof rack to hold my old Thule ski box. Seemed like a good idea at the time, using up some airfoil aluminum extrusion. But, and apart from my crappy welds, I think the end result was a bit off. Here is the link to the original post. At that time I was using an aluminum rail attached to the side of the pop top, it worked but I thought it flimsy.

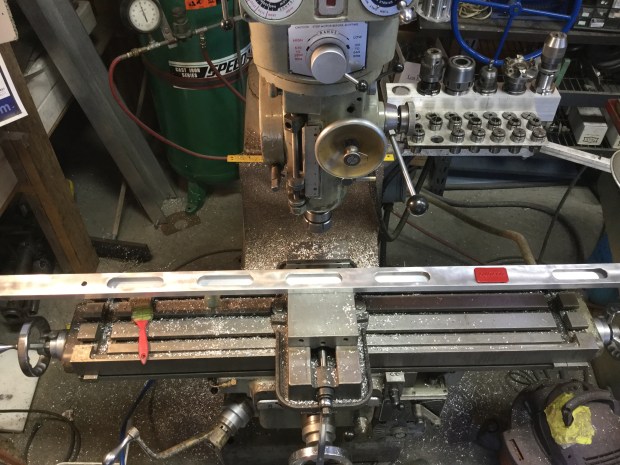

So… I made some new side rails from 1″X2″ aluminum box section. The rear Most section is bent to fit the contour of the roof, and I put in some slots for visual interest and to access the roof rack mounting system.

That red badge is from a Passat syncro station wagon found at wreckers. Annoying that even though the mounting hole for the badge is cantered on the tube, when the badge snaps on it lies off centre, grrr.

The ends of the box section are filled with section of 2″ aluminum tubing, half circles 1″ thick. Welded and blended.

I came up with a novel method of holding the airfoil rack down onto the roof and side rails.

5/16″ NC bolts drilled out and holes chamfered, 1/8″ stainless cable with swaged ends (copper). The shorter bolt goes into the underside of the airfoil, stainless threaded inserts in the aluminum. The longer bolt goes through the box section side rail and tightened and locked with nuts.

That works surprisingly well, the cable tension is good, the rack gets pulled down firmly. The ski box is bolted to the airfoils, so that ties the two airfoils together. But even alone, the rack is very secure on the roof. I’ll paint the whole lot black some day.

Vanagon – what’s this gizmo used for?

Posted by albell in vanagon, vanagon mods on July 5, 2017

Update: vanagon mailing list guesses include prop to keep loose vent window open and holding notes to metal dash. Good guesses and would work, but not the primary intent.

Good friend Stephen gave me this idea. Handy bit of wood with magnet on one end. It’s 1 1/2″ long, 3/4″ diameter. It could be another 3/4″ longer but works fine as is. Extra points if you can guess the wood (I’m looking at you, oldfussbudget). Wood hint, it’s never going to rot.

Oh and yes, can have more than one use, with that magnet and all.

Ok, the anticlimax, the reveal. It’s used to prop open the license plate hatch when checking fluids. Yeah I know you can use the oil fill cap, but I think this is better 🙂

If you want you can store it stick to the hatch. Or maybe better idea is to use it to hold down notes on the dash.

Vanagon – almost foiled weekend trip

Finally, we were able to take off for a weekend trip to one of our favourite places. Weather was to be hot and dry. Packed up Saturday morning and headed out. Alternator light started to glow before we got out of town. Shoot, it came back to me that when I did an alternator overhaul this last winter I made a mental note to replace the brushes soon. Mental note got lost. Had a spare voltage regulator in the van (used, but brushes still workable) and swapped it in. That solved that but then the van started to run oddly. Idle would drop and engine die, ran a little rough. We headed to Simons house to use driveway and I poked and prodded connections etc. Moved the O2 sensor wire away from a spark plug wire. That’s all I could do. Headed back home and the van ran fine. Took the chance and turned around and continued trip. Engine ran well for the rest of the trip. Sooner I put in a new motor the better, it’s so frustrating to trouble shoot this old engine and wiring.

I bought new tires last week. I was running Yokohama Geolandar ats, 215/70 15. New ones were the replacements for the ats, the Geolander GO15. And I went for largest ( some say to much ) that you really should put on the van with stock motor, 215/75-15. Was expecting more of a performance hit than I actually felt. Yes, I did have to downshift on hills that previously I hadn’t needed to, but this was much more apparent on the pavement, not so much in the logging roads ( travelling much slower on those roads).

The ride quality of these new tires are very much better than the old ones. Yes, a little louder on the pavement but smoother ride and on rough roads they soak up the harsh bumps way better. Great grip on loose stuff, and I didn’t notice the lugs getting cut by sharp rocks.

Shade temps were hitting 30-32 C when the breeze dropped. Sun intense, no fog on the ocean ( oh that will come in July and August), just perfect.

Brought the large westy table with us, and it works on the Swellegant™ table mod even better than the smaller table. I’m telling ya, it’s one of the best things I have ever invented.

Dinner was marinated thinly sliced skirt steak on skewers grilled on the Ecoque.

Magnets holding a reflective tarp over part of the side of the van to give the fridge a fighting chance.

If you look towards the horizon, just to the left of that awning guy line, and if you could fly in that direction, the first land you’d encounter would be New Zealand. Amazing eh?

We pretty well just sat, read, drank, ate, enjoyed the view, looked at the marine traffic. Saw no bears, elk, deer. Nighthawks were there though, and a couple of rufous hummingbirds that really liked the red campchair.

Vanagon – a couple of minor fridge mods

Posted by albell in vanagon, vanagon mods on June 19, 2017

Attention!!! Maybe some of these mods don’t work. Doing some tests now to confirm. Yes this is embarrassing 🙂

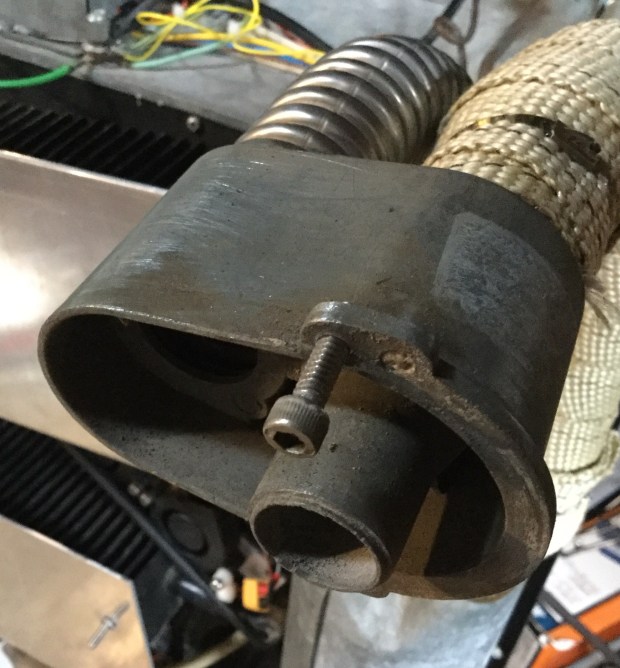

I’m going to try my best to not run down any rat holes in this post, for there are many when it comes to the fridge. I’ll try to stick to the mods that I recently made. Over this last winter I’ve had a couple of westy propane fridges in the workshop, in for some D&C ( that’s dusting and cleaning, not the other). With one of them, I tried out some ideas. First was to insulate the section of corrugated stainless exhaust pipe that really pumps out heat into the van. Just a couple of wraps of Fiberglas tape, exhaust pipe tape.

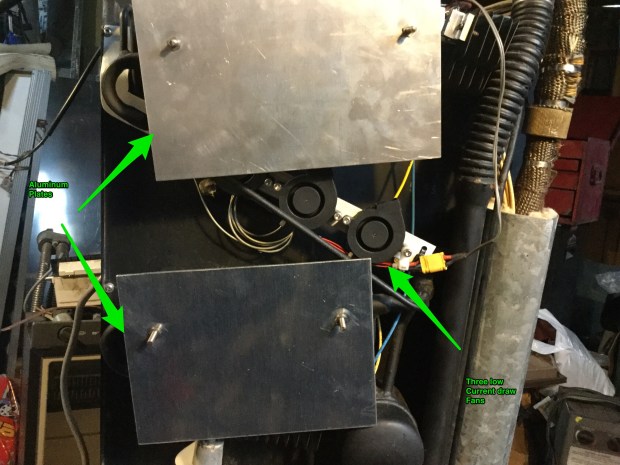

The next mod was a couple of aluminum plates clamped to the fridge cooling fins to help channel cooling air. I know others have made an enclosing shroud back there, I tried that about twenty years ago and I wasn’t very successful in getting a good fit. This time I reckoned that the plates would maybe do 80% of the job with 100% less effort.

In addition to the plates, I added a bank of three small, very quiet and low current draw, squirrel cage fans.

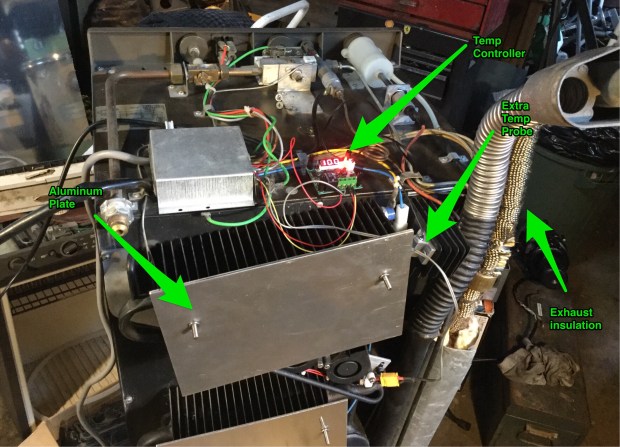

Here’s the test mule with the mods. At this time there was only one wrap of insulation on the exhaust pipe and I added a programable temperature controller and probe to control the bank of fans.

I bench tested this with propane, 120 V ac, and 12 V dc. I fiddled with a programable temp controller and finally decided that even though it was sort of fun to be able to adjust the fan set point and adjust the dead zone ( in effect, adjustable hysteresis) , it really wasn’t needed.

Also found that on propane, the exhaust pipe still gets hot. Not skin scorchingly hot as it was un-wrapped, but still a heat source. Decided to double wrap.

This weekend I duplicated the set up onto my own fridge. I had added a second fan to this fridge some time ago, and I had replaced the stock fan motor with a slightly larger unit. This was working ok, the second fan was fairly quite. Skirting round a tempting rat hole here when I say that I think the stock fan blade works as well as anything in that placement.

I removed that computer fan and installed the bank of three squirrel cage fans. The fans are wired in parallel to the stock fan. And added the plates.

Plates are held on by hooked ends, the straight ends threaded and nutted.

The fans are mounted to a bit of 1″ wide, 1/8″ thick aluminum. Little bit of a dog leg and screwed at one end, the other end cable tied to fridge tubing. It’s in there quite securely, no movement, no rattles.

Double wrap of insulation on the exhaust pipe.

I don’t think the insulation will have any adverse effect on the exhaust tubing. I think the stainless will take the additional heat.

A couple of tips on reinstalling the fridge. One thing I did some years ago was to re-thread the intake/exhaust flange for M4 bolts. The original sized holes had stripped out. The socket headed cap screws are nicer to use.

When you’re trying to line the fridge up to install the sheet metal screws inside the cupboards, a slim awl or a pin as shown is a great help.

And the propane connection to the fridge can be a little frustrating to attach. The line up might be off and the access is awkward. A short wrench is invaluable, this old family heirloom is what I use.

You know, I’m not an expert on these fridges but I’ve found that if all the components are working, the electrical connections good, and the combustion chamber ( and gas jet) is clean, then the fridge lights up easily. Believe me, I’ve struggled with the fridge at times, but I think those days are long gone.

Touch wood

Addendum, later that day…

Dgbeatty commented that I should look to the finned heat exchangers inside the fridge and re-do the thermal paste. That bugged me, I should have thought of that when I had the fridge out. I replied that I had tried to remove the fins years before but had no luck, they were stuck enough that I worried about breaking something. But I tried again and this time they came off.

That old thermal paste came off with WD40, then a rub with isopropyl alcohol.

Of course I don’t have a tub of thermal paste to re-apply, so I did what any redneck would do, I used anti-sieze. I don’t think that’s as daft as it seems. The MSDS for this anti-sieze states it contains 5-10% (by weight) aluminum powder.

And all back together. Replaced the the little CPU fan I had wired up to the top of the fins ( idea is to circulate the cold air, don’t use it that often) with one of the little squirrel cage fans. At the side of the fins. What the heck, it’s going to move some air.

Vanagon – pop top seal replacement and new decals

Posted by albell in vanagon, vanagon mods on June 17, 2017

This is, and i know there are many strong contenders, the most boring post on this site. You’ve been warned.

It’s funny, I mean funny curious, how we get concerned by things that others think trivial. What I mean is that there are so many cosmetic repairs I have to do to my van but what I end up doing is something minor. This time it’s the pop top seal which, while not completely thrashed, was getting tired.

And the the other funny thing is that I don’t like how many of the replacement seals look. I’m not saying they don’t work well, it’s just that they have a vinyl look that bugs me.

Way back in 2001 or 2002, I replaced the stock pop top seal on my old 82 westy with a bulb seal that I found at a local RV store. It had a nice rubber look and had a generous sized bulb and edge grabbing part. I kept that seal when I used the 82 westy parts to camperized my syncro tin top. The luggage seal was the original VW seal and I kept that ragged thing going with glue repairs.

But it was time to freshen things up and I found a replacement bulb seal. It’s a heavy duty seal that I discovered being used at a local boat company. It’s not cheap, and i had to buy more than needed.

From left to right, an unused portion of the old seal that was left over from the 2001 install, the used old seal, and the new seal.

Right away you can see the new seal has white grippers and a slightly deeper gripping portion. Also has that inside lip that really doesn’t have any effect in the pop top install.

My lord this is boring. Ok, So i bought new bulb seal and I put it on the pop top. Also used the seal on the luggage rack and it worked out just fine. That heavy bulb seal sat down nicely. Left the seal a little short at the rear to let water drain. Maybe I’ll need to cut a channel in the bulb at the front corners for more drainage, we’ll see.

There is one issue with this type of bulb seal on the pop top and I noticed it with the old seal. And that is there is a bit of a ledge between the seal and the pop top that collects dirt. What I might do is run a small bead of clear silicone caulk along the edge.

And the decals had really not weathered well. I don’t have one of those rubber wheels that you use with an electric drill to remove decals so I was thinking it was going to be a chore getting them off. But turned out that a plastic scraper and heat did the deed in a jiffy.

Bit of a tell left after a wipe down with isopropyl alcohol.

New decal, which btw are 3M reflective black, going on.

Looks ok, but I’m pants at this sort of thing, never seem to get the decal just right ( you’ll see that with the rear decal)

One last boring pic. The van is a daily driver and this is the wet coast of Canada and that combo means lichen on the pop top. Scrubbed the top and the interlux brightside on part poly urethane paint I used 7 years ago ( and only one coat, cheap me) cleaned up surprisingly well.

Vanagon – the aluminum obsession continues – sliding door card

Posted by albell in vanagon, vanagon mods on June 16, 2017

It wasn’t my first choice of materials, but it was given to me by Thomas and I had to use it. 2024-T5 aluminum is hard to weld as I found out with another project. That project might get some air here. I just jumped into it and didn’t pay any heed to the letters printed on the stock, I thought I was just having a bad day at welding. It’s also not happy being bent, snappingly not happy.

So I had a couple of good sized bits of 0.063″ (1.6mm) 2024 that I really couldn’t readily use. Except… my sliding door card had been mangled by the previous owner and although liked the stock vinyl and cloth cover I hated that it was warped and tattered especially at the rear end.

I got that red mist in my eyes and made a replacement card from the aluminum. Yeah I know, it’s not the best stuff for this application. It’s cold, it’s thinner than the stock cards, it’s harder to fab, and I will have to cover with some sort of fabric. Oh speaking of the fabric cover I’m intruiged by this stuff from Seattle fabrics, the link here. I’d stick on a thin layer of open cell foam before the fabric. But we’ll see what I can find, don’t worry it will be covered and slightly insulated.

I just laid the old door card on the metal stock and traced the outline. I popped in holes the same size as stock thinking that maybe the stock clips would hold, but as it turned out they wouldn’t. The aluminum was just too springy to pop conform to the curve of the door without pulling the clips. That meant I had to slightly enlarge the clip holes in the door to accept some 1/4-20 riv-nuts. And then I used 1/4-20 flat head stainless screws and finish washers to attach the panel. And boy oh boy, screwing the door card on is so much more secure than those plastic clips.

The pics follow 🙂

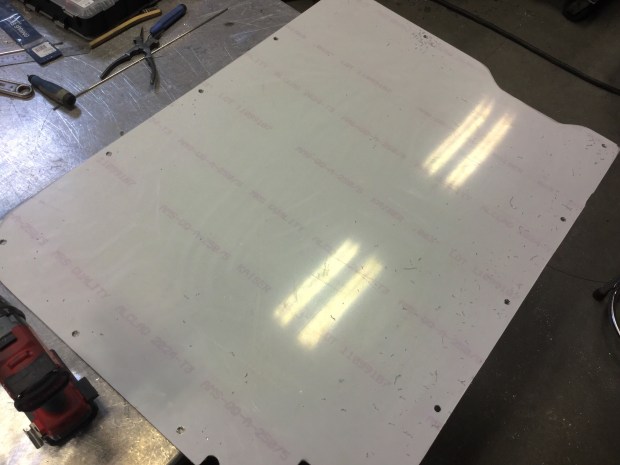

Stock cut with protective plastic film still on.

Yeah, hand cut so the wobblies show.

A bit of a “hall of mirrors” effect in the van. Maybe keeping it uncovered will make the inside of the van seem larger.

Vanagon – westy kitchen unit score

Answered local buy and sell ad and met up with ex-vanagon owner Warren. Really nice guy selling some left over parts including a later model westy kitchen unit ( the type that has the lower front end and different lid), a rear heater, home made pressure bleeder for brakes, and various other little bits and bobs. The kitchen unit does not have the stove parts nor the fridge. The space where the fridge went has some shelves installed.

The later style kitchen unit allows the driver seat back to recline a little more. I’d like to incorporate that into my earlier style unit but that mod will have to wait. But right away I could use the larger capacity drawer.

Early vs later drawer.

More room but still being used as junk drawer.

The faceplate wasn’t perfect but much much better than the one I had. So it got swapped in. But still using my black painted indicator panel. I think I’m remembering correctly, krylon espresso satin brown is a close match.

Vanagon – Semi hi top pop top in Mexico

Interating vanagin and Dutch couple Simon met during his recent Mexico trip. I don’t have many details, but I think it’s a Reimo top (and limited edition ) diesel, twin fuel tanks, syncro. I bet a few of you out there know this couple.

Multiple dope slaps for shooting this video in portrait mode, but still very much worth a look.

Oh and yes, that’s a Thule van door lock on the sliding door.

Vanagon – that westy table mod update

Posted by albell in vanagon, vanagon mods on May 30, 2017

A couple of things to say. The somewhat clunky adapter that I made to allow the newer style table top to fit the older style table leg has raised the table enough to partially block the USB outlets I put in the vent grill on the side of the stove unit.

I think there is enough meat in the adapter to take away and lower the table. The next thing is the knob that tightens the table leg to the cupboards. I bet most of you find that it’s difficult to tighten that knob enough to prevent the table from moving a bit when driving. Many have made retainers of one form or another. Maybe magnets on the van wall, maybe Velcro. You know what I mean. I did something along those lines on my old 82 westy. But this time I thought about changing the knob to something I could tighten, and equally as importantly, loosen easily. So I quickly made a knob substitute from some 1 X 1/8″ stainless flat bar. I welded a M10 socket headed bolt to it and added some “speed holes” ( as Travis would call them ). Much easier to tighten and loosen and when tight it holds the table firmly. No need for any other fix.

It’s not very stock looking, but it’s not an irreversible modification.

Vanagon – westy table, old type leg with new type top

Posted by albell in vanagon, vanagon mods on May 28, 2017

I used the interior of my old 82 westy when I converted the syncro tin top to a westy. You might know that the old style table leg to table top connection is a spigot into a tube arrangement. The newer type has the end of the leg flattened and a bolt runs up thru that and into the table top. The later style is much better, in as much as the table doesn’t have the short spigot on it and stores a little easier. In addition, I never did have the front table or table leg until a few years ago when good friend Stephen gave me the pair, but the newer style. That was around the same time the kid left home so big table when camping wasn’t needed, we just used the front table. Actually, the front table was used much more often in the Swellegant™ conformation.

But then the other day I was poking around in the first circle of hell, aka the home workshop, and found two late model large table tops. I had forgotten that same good friend Stephen had dropped them off after salvaging the edge trim. I grabbed one and cleaned it up, pulled the edge trim off my old style table, and whacked it on. So now I had a functioning late model table and I could use it with the Swellegant™ table stand and have a bigger outdoor cocktail table. And who doesn’t want that?

And then I got to thinking, why not make something so this larger table could be used with the old style table leg? I had a bit of aluminum round stock that I had machined to make shaft aligning tool which turned out not to be needed so I whittled it down to make a table adapter. Welded a bit of flat stock with holes in it to a suitable bolt and bob’s your uncle, a table adapter. It’s a bit clunky but note that’s the flat stock handle used to tighten the table top to leg is much easier to use than the stock round handle and I made it so that the handle ends up more or less above the table leg when tight. That’s just to reduce the chances of snagging something on the handle.

Oh and the old stock knob that screwed into the tube on top of the old style leg, I replaced with a short bolt which hits the flat spot machined on the side of the adapter. Don’t need to touch that again, the table top is held on by the through bolt ( the through bolt which has the holy handle).

Ad the table in place. The short front table in this instance.

Oh and just to be clear on the table leg differences between old and new, here is a new style rear table leg which I had shortened to be used up front. Completing the circle as it’s going to good friend Stephen.