Vanagon – bent syncro bash plate

Or syncro bash plate bent, or bash plate syncro bent. I was under the van the other day patching up my rotten exhaust for the umpteenth time and I noticed this part of the stock skid rail/bash plate bent. Worryingly close to the engine and I don’t recall hitting the rear end *that* hard this summer.

Lotus Elan

Posted by albell in other cars on September 24, 2012

Seen locally, another one of the dream cars of my childhood. I still want one.

Vanagon – front brake fandango

Posted by albell in syncro, syncro specific repairs, vanagon on September 19, 2012

I hope the story that follows will help someone be less stupid than I have been the last 2 days. No, that doesn’t sound right, no one would have been as dim as me notwithstanding.

Story starts with passengers complaining of squeaks from front left brake/wheel. Further development was noticing a clunk/rattle when going downhill on washboard/rough roads this last weekend. Noise seemed to be affected by brake application. Signs say examine front end and brakes. So I do that, could not find any loose or broken suspension components but did find that my brake pads were getting thin, and one pad on pass. side had a broken spring. So here is where I should have sat down and thought things through more. New pads are a good idea, but what about new rotors too? I did measure old rotors, they were within wear spec, so ADD boy here rushes out and buys some expensive Pagid pads and leaves rotors alone.

Quite a difference in thickness between old and new eh? Hint: that should have triggered a response in my brain other than “gee, look at the thickness difference”. Oh and another oversight, I mentioned that I measured the old rotor thickness, doing that I did note the ridges on the rotor (peripheral and internal) where the pads do not touch. I didn’t think that would be an issue, ha!

So I popped in the new pads. Bentley describes the procedure well, but did I do a careful reading? No, I didn’t. I removed both bolts from the caliper slider and removed slider to install pads. That is NOT how to do it. There are bold warnings not to re-use those slider bolts and the new pads came with just 2 new bolts (with pre-applied thread locker). I was puzzled by this, I thought I was shorted 2 bolts. So I used loctite and re-used the old bolts. This was both good and bad as you will see later. I finished pad replacement Monday evening and did not take van for test drive, yet another dumb-assed mistake. Next morning I had an important errand and as I drove out I noticed a rubbing/clicking noise from front right wheel. Bloody hell, drove back and popped that wheel to look. Rushed examination, pulled pads, noticed scoring on inside pad where it was hitting the un-worn area of rotor. Aha I thought, and beveled that part of pad a tad with stationary belt sander. Noise still there. Borrowed car and rushed out. I had the chance to drop by Autospiel that day and talk to Russ about this noise. I explained situation, he asked if I had checked that the rim, or balancing weights were not hitting caliper, I said no, I believed it was the pad on the un-worn part of rotor. Why don’t I listen and think? I decided to by a couple of new Brembo rotors from him (39 bucks a piece), and at same time, noticed them on the counter, a set of radius arm bushings (mine are old and worn out, I’ll post about replacement later, nothing to do with brake job). Got back home and set about rotor replacement.

This time, doing it right. First remove the pads. Undo lower bolt of caliper slider, in this pic I have 13 mm wrench on bolt and crescent wrench on flat of slider rod.

With that bolt out, the caliper body swings up and the pads exposed. Pull out pads.

Now those aneurism inducing 22 mm bolts (2) that hold caliper body to suspension upright. They are on tight (200 ft-lbs) and not much access for the lift deprived driveway “mechanic”. Shoot, forgot to state the usual warnings, ie support van SECURELY on jack stand/good wooden blocks during this procedure. You are really putting a lot of grunt into the van when loosening and tightening those bolts.

Ok, caliper off and hanging on breaker bar stuck in suspension. The slider part came off and is sitting to the right in this picture.

That hex socket bolt need to be removed, 5 or 6 mm? can’t recall.

Then the rotor should slide off the hub. Well, it started to but then hung up on something. At this point I really was not sure of anything, I consulted Bentley again, and again, finally used a puller.

I think it was this rust that was making the rotor difficult. Look at the state of it! What in the name of all that is holy was I thinking when I first decided to leave the rotors alone?

What it looks like with rotor off.

New and old.

New rotor on. I must say that it did give me a warm fuzzy feeling to look at it.

Caliper body re-installed and 22 mm bolts torqued back up to, ugghh, 200 ft-lbs. Pads installed, caliper slider swing back down into position and new bolt used in bottom position. You may find that you have to press in the brake piston to get the caliper to fit over new pads. I used a C-clamp to push piston in.

Other side done, wheels back on, tools put away, brow wiped. Ok, test drive…. rub, rub, rub. Son of a gun (or words to that effect), the noise is still there. Noise goes away when braking, that is a clue. On passenger side I had installed a no-name (drivers side is a Girling) caliper a couple of years ago when I broke the nipples off both calipers. I cannot recall why I got a Girling for one side and a no-name for the other side, but that is the way it is. I looked closely at the caliper. Oh yeah, scoring. So it seems that the added thickness of the new pads pushes the slider outboard enough to hit the rim (stock 14″ steelies yeah, yeah, I know I need bigger wheels. It is on my to do list)

And one of the curious little tits on the rim that is hitting.

Allright! Time to do some real work. Blending disc.

Grinding disc.

Caliper modified.

And yes, happy ending. Rubbing noise gone, and as a bonus, the brakes work.

Summary time:

– read the manual closely, don’t be a dolt like me and skim.

– replace rotors if replacing pads. Don’t screw around, the rotors are so inexpensive it is not worth having them turned. I suppose if you liked experimenting with different pads rotor replacement would get expensive. I have read that for good pad break in, the rotors (if not new or turned) should be scuffed to remove any old pad compound. But after all I went through, I’d recommend just buying new rotors and be done with it.

– be careful with those 22 mm bolts holding caliper on upright. The buggers are awkward to get full force on, don’t let wrench slip and for god’s sake support van well.

– think before and during doing this job. Please don’t be like me.

– Russ told me that the Pagid pads I chose are excellent, the only downside is that they make more dust than the stock pads. That might be a concern if you had alloy wheels.

Trip – yes, once more to Camper Creek area

Octopus

Good friend Dave remembered me saying that I’d take an octopus if his commercial prawn fishing friend had any to spare (a by-catch that is frozen and used as halibut bait) and brought over 8 of them – frozen. I’ve never cooked a Pacific Giant Octopus before, and all the recipes I have, and that I could find on the net, were for cooking smaller octopus. I gave one method a try and I took pics along the way.

The octopus, not fully thawed, in the sink. The slime on the skin rinses off easily and after rinsing I cut the tentacles off. Forgive me, but for this first go I didn’t use the head.

In the stock pot.

Water, onions, pepper corns, bay leaf. Simmered for an hour or so, scum removed as best I could.

As I said, about an hour or so or until paring knife could poke into a tentacle. Pot dumped into colander and at this point I was disappointed to see not only the skin but the suckers falling off.

And this was the result. Lots of shrinkage and with no skin or suckers, it really didn’t look at all like what I wanted.

I made a provencal style tomato sauce (onion, garlic, tomatoes, parsley, capers, olives, etc) and popped the cut up tentacles in at the end, just to heat them up.

It wasn’t bad, but not great. I’m going to try again, different approach.

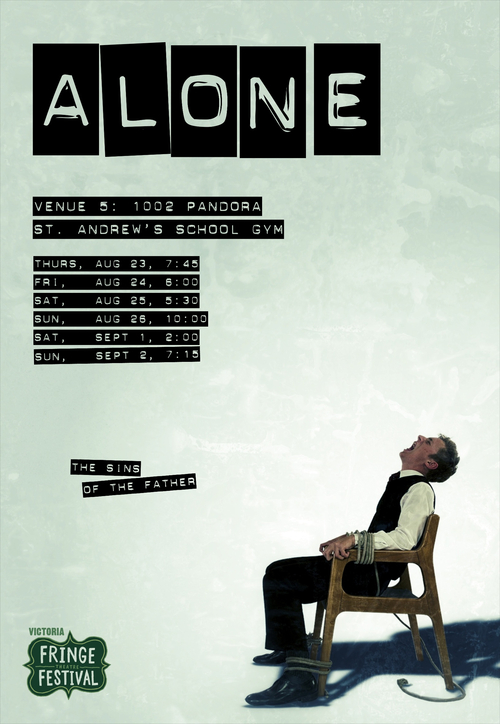

Victoria Fringe Festival – “Alone”

I have to plug the Fringe play my son Michael is acting in, Alone. Here is a link to a review, and another.

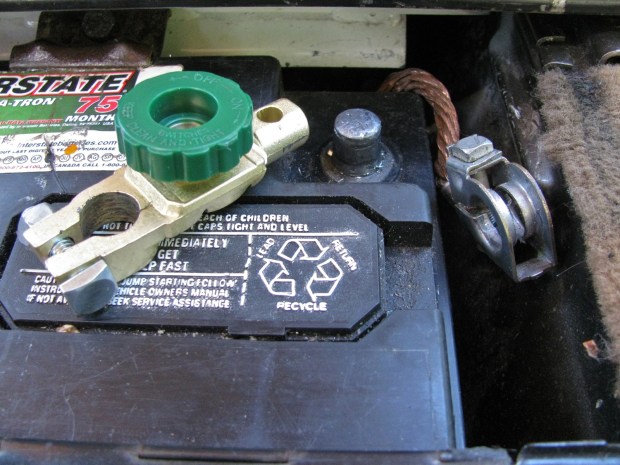

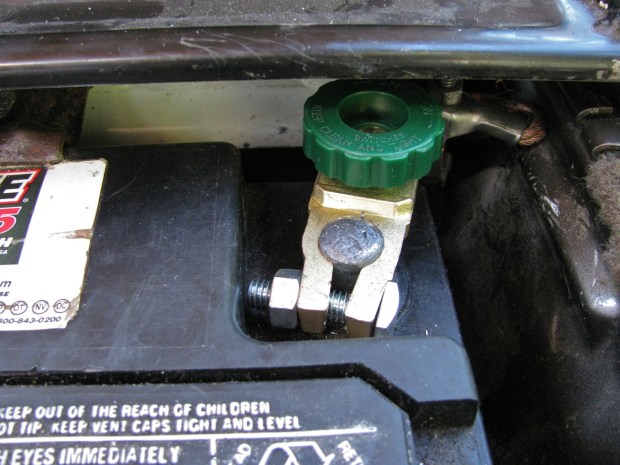

Vanagon – main battery kill switch

Posted by albell in vanagon, vanagon mods on August 24, 2012

There have been a couple of disturbing posts recently on the Samba and on the Yahoo Syncro mailing list about Vanagons moving on their own and or catching fire due to massive electrical faults. A short somewhere in the ignition wiring causing the starter to engage etc. It’s enough to make even the most happy go lucky owner shiver. A recent post to the Yahoo Syncro group mentioned this kill switch – Amazon link and how it was possible to mount it on the negative pole of battery (starting battery under front passenger seat of gasoline Vanagon). I happened to be out Langford way today and dropped in to Princess Auto and found what looks like the exact same switch ($9.95).

It is a squeeze to get it on the negative post of the battery (I installed the Westy swivel seat base on that side, that does not help matters at all), and the taper on the switch is designed, I think, for the positive post so you have to be sure to tap the switch down to the base of the post.

It works as advertised, a turn of the green knob connects/disconnects the ground. I have a house battery under the driver’s seat (and a fused distribution box) that supplies power to the circuits needed during camping i.e fuse #3 circuit (which powers radio, interior lights, cig. lighter, clock) and power to the kitchen. The kill switch will be used when van is parked for a time, or if I feel especially paranoid. The battery compartment lid does fit over it ok.

Vanagon – sliding door quietening hack

Posted by albell in vanagon, vanagon mods on August 23, 2012

As seen here on this Samba thread and I got the tape from Lee Valley, (link to product page). I’ll cut to the chase and answer the question “Is it worth it?” – yes. It really does make a difference in the noise made by the sliding door as it is opened and closed. This is on my ’86 syncro which has the improved sliding door set up that started in ’85. That improvement in door design is one of the nicest mods VW made to the van over the years. Ok, on to the hack.

First I pulled the track cover off the side of the van. Two screws at either end of the cover and then some wrestling to get it off. I’m not going to tell you the exact motions needed to get the cover off, but for goodness sake’s don’t pull the bottom of the cover out towards you. That is not the way it goes. It comes off straight up but you do need to clear the tabs that the attachment screws use and that does mean you have to ease the cover out a little towards you then back to the van. Sometimes grime and crap glues the cover to the van, so be careful.

Cover off and this pic shows the track one of the rollers rides on. You have to clean and degrease. And this is when I realized that I would only be doing a half assed job. You see the paint is worn off the track, and when I stick on the tape there will be no grease to keep that track from rusting. The best thing to do would be to paint on some POR15 or something similar before sticking the tape on. But I have a really annoying summer head cold right now and I just didn’t have the energy.

The forward end of the track. Two rollers there, and four surfaces to be covered in tape.

The lower track covered in tape. The tape is folded over the top edge of the track. It stuck on pretty tight. Both vertical inner surfaces of the track above this one was covered too.

I did this mod to my old ’82 years ago – a bit of self adhesive bitumen impregnated fabric to try and stop the track cover from acting as a sound board.

I put the cover back on and tried the door. Much better, really, I’m not joking. But still not as quiet as I thought it should be. I could hear noise from the upper track above the door opening. A roller bearing here as well, not the old plastic block of the pre ’85 doors. Tape applied to the outboard vertical surface (the only surface that showed sign of wear).

And I cleaned up the lower track surface, the one at the foot of the door. The track that is often dirty and greasy and rusty. Now I have my share of rust on the van, but fortunately the track surface was good and it got the tape. And now some proof. Note that the last clip that is titled “tape added to upper track” , the lower track had been taped too. God I have to deal with the rust on that door.

Austin Seven Chummy

Posted by albell in other cars on August 14, 2012

At the local Brit car goldmine, Owen’s, a true classic (the Healey and the Syncro are too). First time I have seen one in the flesh, I want it, really want it.

Trip – Camper Creek watershed again

My wife and I revisited the Camper Creek watershed that we went to a month ago. We had it in mind to see if we could find the trail down to Camper Creek, near the park boundary. So we set of on Thursday afternoon and arrived at our campsite around 3 pm. Funny thing about my stitched panoramas, the centre portion of the pic ends up narrower than it appears in real life. A bit of fog on Juan de Fuca strait, Neah Bay is over there on the other side, close to the middle of the picture and some smoke from (I think) slash burning up the hillside to the right of Neah Bay. Cap Flattery to the far right.

This fog evaporated as the afternoon wore on and we could see some of the marine traffic in the strait.

Neah Bay is behind the leftmost ship.

I’m guessing you get the idea that we didn’t do much once we got to the campsite, not much except sip cocktails, look out over the strait, and read mystery novels. Oh and then before you know it, it was dinner time.

And three Nighthawks appeared, diving and buzzing. Very hard to get a picture of them.

A bit of an apocalyptic sunset.

Next morning the fog was back.

I took us half the day to pry our selves out of the chairs and stop reading long enough to do some exploring. We found what we think is the trial down to Camper Creek, but the dogs were acting excited and we decided not to go down it for fear of running into something that the dogs would chase. There are lots of bears around this area, no shortage of bear poop, and our dogs have a history of going after them. So we decided to drive as far northwest as the logging roads would allow, heading to where Walbran/Carmanah Park “T’s” into Pacific Rim National park. It is a logged area between Cullite Creek to the north, and Sandstone Creek to the south. Interesting area but no great campsites so back we headed to the original spot. On the way back we had a dip in a nice pond in a gravel pit (often find blasted areas at the side of the roads. The rock used for logging road construction). I’d give this pit 4 out of 5 stars.

Back to the book. I was reading “Voices” by Arnaldur Indridason. The fog never did lift form the straits that day. We wondered about the number of fog days Neah Bay must have. Here is a link with some weather data. Seems that Neah Bay has at least 14 days per month of fog.

As the sun set, the fog crept up towards us.

But then the wind changed to a land breeze and the fog was pushed back a little.

Following morning was pretty darn nice.

We packed up around noon and headed back out towards Port Renfrew. We did explore some logging spurs, nothing much to report except to say that expect some bugs when going down dank, alder lined roads like this.

There was one productive side trip, up Braden main a few kilometres. A couple of female elk trotted across the road, finding and fumbling with camera got me this “Bigfoot spotted in PNW” class picture.

Then we found a nice spot where a bridge crosses Braden Creek.

We had a dip in the (cold) water then headed home. The van ran fine throughout the trip, but I’m really starting to get tired of the front springs – I still have the originals (tin top) on, and they are just not up to the task of supporting a westy conversion. I’d like a little more lift up front and I had been thinking about spring spacers, but now I’m wondering if those 2wd westy springs I have might be worth a try. I’ll need to look over the spring data again.

Vanagon – my inattention one year ago bites me

Posted by albell in vanagon, vanagon mods on August 7, 2012

So I notice the seal on my luggage rack was detaching from front rack, damn 3M weatherstrip adhesive failed me (see here for glue on pics). So I pulled off the luggage rack to re-glue the seal and I was shocked, shocked I say, to find some rust spots on the roof under the seal. Pic below is after I scuffed with Scotchbrite pad.

Was it just abrasion by the seal on the metal roof? No, looking at the seal I could see bits of rusty metal embedded in the rubber. Bloody hell, looks like metal filings trapped between the rubber and the roof. A lot of filings were created when I was cutting up the roof to add the pop top, and I thought I had cleaned them all up before installing the luggage rack. I’m sure I did, perhaps some fell through the drain holes in rack and lodged themselves under the seal. In any event, it was my fault .

I masked off and painted some POR15 over the affected parts. I scrubbed the embedded rusty bits from the seal and re-glued it back on the rack, this time using clear silicone caulk.

While I had the rack off, I glued on some stainless mesh on the underside of the (5) drain holes. Some have used little stainless filters that you find on some garden hose connections, but as I had the stainless mesh… I used “Automotive Goop” to glue the mesh onto the fiberglass and that glue worked very well.

But that rust, what a pain.

Vanagon – roof rack mounts

Posted by albell in syncro, vanagon, vanagon mods on August 5, 2012

A bit of a kludge, but I wanted to get some racks up on the van to carry my son’s kayaks and perhaps a Thule roof box. My old towers that I used when the van was a tin top would have been pretty tall on artificial rain gutters mounted to the pop top. We had another Thule rack, used on my wife’s Subaru and is one of those “sits on the roof and clamps to door frame” types. I decided to use it but swapping in the longer bars from the tall tower set.

Ok, to the scrap bin for this bent bit of 1/8″ stainless and away I went with the angle grinders.

I must have been hepped up on goofballs, this was the result for the rear most bracket (to be attached via pop top hinge bolts)

I drilled them for mounting and put them on. They looked, in a word, ass. Ok, back to the pile o’ metal and out with some 3/16″ (!) stainless flat. Cut, drill, grind, etc. and got something a little better. The first attempts were cut down to make the forward mounts and here are the results.

The racks are pretty firm, even with the forward pads not 100% in contact with roof.

Garlic and shallots

The larger ones hung individually are the main crop (hard and soft necked). The bundled small bulbed ones are volunteers from another part of garden. The volunteers are nice tasting purple hard necks we planted years ago. Next season we will give some of them a better chance.

Some shallots hanging up there too.

Trip – Nitinat and Klanawa

A few days exploring the Klanawa river watershed, this general area – from Nitinat falls on the upper right, to Blue Lake on the lower left.

First night spent on Nitinat river, near the falls. It was raining on and off, plus their were other campers 300 metres downriver, we headed off next morning to find a better spot.

We had brought along the GoPro Hero 2 cam, and the only even close to worthwhile vid we shot was this less than exciting “vanagon in puddle” sequence on the road out of the campsite.

We headed northwest, over into the Klanawa watershed, and followed the river downstream. We stopped here and there, looking for a nice spot. An example of a side track – grey skies but it was mild and not raining.

My son trying “logging parkour”.

And at last we found a spot, secluded lake, not logged.

Nice big bear poop close by.

Next day was sunny.

And off we went again, further west, looking for a spot on the Klanawa river and no, we didn’t want to camp under the bridge. We did swing past the spot on the Tsucowis that we camped at 2 years ago, but it was occupied. We went part way around Darling main loop, and took one spur that led down through an old (1960’s?) logged area and found a skidder. I’m thinking that someone took it down there to salvage cedar logs for shake block cutting.

We didn’t find any nice spots, so back east to the bridge across Klanawa and then west again on south side of river. Finally found an OK spot west of Blue lake. Slash camping again, but a nice view.

Plenty signs of elk.

And bear, of course. Dogs are tired out.

As the sun went down, the marine cloud formed. That’s the west coast trail way down there in the cloud.

The moon was pretty, sky red with smoke from Russian and Alaskan fires?

The lads slept in the tent that night.

Nice sunny morning.

After breakfast we packed up and made a concerted effort to find a trail down to the Klanawa. Some false leads and a lot of bushwhacking later, we got there.

It was a lovely spot, virgin forest and clear water. At five pm we headed back to van, and then home. Van ran fine, but we were heavily loaded and the stock tintop syncro springs are not stiff enough for this sort of thing. Perhaps my old ’82 westy springs might be installed in the front and coil over shocks to help the rear?

Vanagon – syncro front spring removal without spring compressor

Posted by albell in syncro, syncro specific repairs, vanagon on July 19, 2012

The other day while replacing the upper control arm bushings on the van I wondered if the spring could be removed without using a spring compressor (Bentley shows compressor being used). I asked on the Yahoo syncro group and a couple of listmembers said it could be done, and they have done it. So today I had a go at it, and at the same time try out the spring spacer I made.

I have to warn you, while this procedure does not expose you to the same dangers as using a compressor , there are dangers to life and limb. That might sound like hyperbole but it isn’t. Please take care if you do what I am about to describe, take it slow, think, be cautious.

Also, what will be described was done on a van with stock springs and with a modest spring spacer. I do not think that it will work with longer springs or thick spacers.

Ok, on with the show. Van jacked up and supported by some solid 8X8 shorts, wheel off, sway bar drop link disconnected, radius rod/arm removed (inner adjusting nut not moved). The lower shock bolt loosened (22 mm socket).

Upper ball joint disconnected, those 2 socket cap bolts.

At this point I was not sure how this was all going to work, seemed like the spring perch would hit drive shaft.

Plastic cap removed from shock shaft end, 17 mm nut loosened but not removed.

Bottle jack supporting shock through hole in lower control arm.

Shock bolt was driven out easily.

And look at how clean that bolt is. I’m lucky, while I have some nasty rust on body, most if not all of the “mechanicals” are in great shape.

When the bolt was driven out and the bottle jack released, the lower control arm fell down. I did not expect this, of course in hindsight I should have.

The 17 mm nut was removed from top of shock and then shock and spring fell out.

Slight digression here, comparing the orange spring (2 white stripe code) from my ’82 diesel westy with the newly removed syncro spring. 20 mm difference between them. Confirms IG16 Wiki data.

And what do you know? The spring pads are different after all. Same part number (although writing this now I recall the syncro spring pad part number has an “A” suffix).

Shock fully extended with syncro spring.

Shock fully extended with orange spring. I would say a shock shaft extension would be need to use this spring in the syncro.

Side by side comparison.

I had to make some slight adjustment to the collar of my spring pad spacer to make it fit the syncro spring pad. Needed to reduce collar diameter a few millimetres

My T-handled tool in through access hole under seat to engage and guide shock shaft up through hole in shock tower.

The shock spring combo needed to be drawn inward to allow shock shaft to go up through hole in tower. I used a ratchet strap.

Here it comes, I’m using the bottle jack to push against the bottom of the shock. Lower shock bolt is installed.

You have to guide the shaft so that the step on the shaft does not get caught on edge of hole.

There you go, installed with spacer. You can see “shadow” line on spring pad that shows how much was in tower without the spacer. I did not re-attach sway bar or radius rod, but did put on wheel and drop van to ground. I bounced van as best I could and measured hub to fender distance. It looks like the spacer did the trick, now 19.25″ at front, 19.125″ at rear. Very preliminary measurement, probably will be a little different after driving.

So then I took it all apart again and removed spacer. I only have one spacer made, but the exercise was worthwhile – I can remove spring without a compressor and I refined my spacer to fit right.

And a bonus, I think I found my pesky squeak – it might be the bushing between sway bar drop link and the sway bar. I had made my own bushings from polyurethane skate board wheels, I greased them during this work and now squeak is gone.

Vanagon – syncro front spring pad

Posted by albell in syncro, vanagon, vanagon mods on July 17, 2012

I think I mentioned in my post about upper control arm bushings that I was considering further tomfoolery with the front suspension. What I have in mind is a modest front ride height increase – 1″ at the most – to compensate for the weight that the camperisation added to the original tin top. Currently I have approx. 19″ from wheel centre to fender edge on the rear (one extra stock spacer above rear spring) and 18″ from wheel centre to fender at the front. You probably know all the approaches to ride height adjustment, and no doubt have your preferences. I’m going to have a go making some spring pad spacers, similar (but not identical to) what Futbus in the UK sells.

I discovered that the spring pad is the same for both 2WD and syncro, so I could make a spacer to fit the 2WD stuff I have on hand. Here is the spring pad, underside that fits onto end of spring. Yup, that orange paint is there again. BTW, the spring (from ’82 westy diesel) had 2 white paint marks in middle of coils. The closest match I have found is the 2 beige mark one listed on the IG16 Wiki page about springs here. Do you get the idea that I am tempted to try these spring out on my syncro despite the 20 mm or so longer length? I am, but I want to have springs side by side on bench to confirm length differences. IG16 chart says it’s 20 mm diff, and that would translate to a 33 mm ride height increase (all things equal, ie spring rate). That is a tad more than I am shooting for, but so close as to worth trying.

Oh BTW, “x” amount of lift at spring translates to approx. 1.66 “x” at wheel. Slightly different multiplier at rear. The IG16 Wiki explains more.

You can see how the spring fits into spacer and the remnants of the tape that holds spring to spacer during installation.

So back to the additional spacer idea. I had this doughnut shaped bit of aluminium, was going to make some other goofy thing out of it, but never did.

I wish it was thicker stock so that I could have had a longer collar.

As is, I made the spacer 16.75 mm thick, and the collar 8 mm. The stock was originally nominal 1″ thick. I made a little bit of an effort to radius the top corner to mimic the stock rubber pad.

And the rubber pad pushed onto the collar of the aluminium spacer. This pic could be a little confusing, there is an aluminium disc under the spacer, more salvaged scrap.

Whoa! There’s that orange spring.

Pad and spacer on spring.

I probably will use some adhesive between the pad and the spacer. Seeing as I am just trying to bring ride height back close to stock tin top specs, I don’t think I will need to extend the shock shaft at threaded end. More on this to come later.

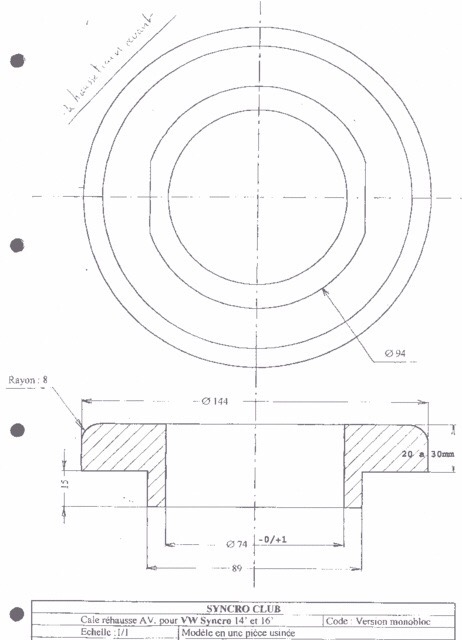

Addendum may 2017

Here is drawing I found in my files for Beau, pretty close to my estimates I mentioned in comments. Thickeness can be altered to suit of course. Don’t forget the multiplier effect of shim to effective lift.

Vanagon – syncro – VW tool 3141 substitute

Posted by albell in syncro, syncro specific repairs, vanagon on July 17, 2012

As I am planning on fiddling around with my syncro’s front springs and shocks I thought I might need a tool to guide the top of the shock back into position when re-installing. Bentley calls for VW tool 3141, the best pic I could find with a quick search is this Snap-On one. I had some 1/2″ diameter aluminium rod handy, and a M10 X 1.00 tap (same thread as used in pressure sender on engine, I needed one to make my sender relocation manifold). The lathe made making the tool easy, shaft is a press fit into handle and is pretty secure, but I probably still need to blob on a bit of weld on the joint.

End of shaft.

End of old 2WD front shock – it has the same thread.

Tool screwed onto end of shock.

I hope to be able to show you how it is used when I pull the front springs from the van, but I need to borrow a spring compressor before I get going with that.

Vanagon – syncro upper control arm bushing replacement

Posted by albell in syncro, syncro specific repairs, vanagon on July 15, 2012

So on our last trip I noticed a squeaking when suspension moved, noise coming from front driver’s side. I suspected upper control arm bushing so I set about replacing them on that side. It is a pretty straight forward job, and here are a couple of diagrams illustrating where the bushings are.

I jacked up and supported driver’s side front of van and removed wheel. When I detached the upper ball joint I could move the control arm by hand, and the squeak was there. 19 mm nut on one end of camber adjusting bolt, other end is 14 mm socket. Arm off and in the workshop.

Close up of one bushing.

Other side of bushing. There is a good chance these are originals.

Here is one of the new bushings. Vaico brand, I don’t know where they fall in the quality line up, but I got them in trade for some used vanagon parts. There is a great Samba thread on UCA bushings here.

I wondered if an O-ring would help keep any grease in.

Then I tried some silicone over the O-ring, a variation of what Tencentlife did in above mentioned Samba thread. I ended up removing the silicone and adding a second O-ring.

Now getting the old bushings out. I don’t have a press so I used a bit of aluminium tubing, a biggish socket, and an old 2WD control arm bolt, and a heavy hammer to drive the bushing out.

Look at that clutter. Workshop is in a real sorry state.

Old bushing out.

Bore of UCA where bushing fits. On the syncro it is a simple press fit, no spot weld needed.

Using a vice to press new bushing in.

Part way in. Ok, you’ve noticed that I painted the UCA. A very casual crap job and wasn’t needed (original paint still good), but I had a can of orange paint and I thought it might look cool. Overnight drying time was not enough, paint still soft, came off here and there. Perhaps I should lock up the paint.

A bit of pop can in UCA to keep a large socket in place while bushing driven home.

And the other bushing pressed in.

Out at the van, rear of support where bolt goes through and eccentric washer sits.

Front of support.

Rear eccentric washer in place. It was a fiddly job offering up the UCA into correct position and not have the washers fall out.

But in it went finally. Everything re-assembled. Guess what? I still have a squeak!

Next post will deal with camber adjustment and perhaps finding the squeak.

Vanagon – pop top hinge bolt replacement

Posted by albell in vanagon, vanagon mods on July 15, 2012

File this under “design elegance – fail”.

Quite a while ago I fooled around with homemade substitutes for the truss head bolts used on the pop top. The bolts which invariably end up rusting and staining the fibreglass. However I never did get around to replacing the hinge bolts, I had this notion that I was going to incorporate some sort of clever plate that would double as a roof rack mount. Well I never did do that and this morning I set about to make some simple washers. I used some aluminium round stock and some phillips head M6 X 1.00 stainless machine screws and produced clumsy, but effective, truss head substitutes. I suppose a good excuse is that I needed to make 8 of them and I really could not be bothered beveling the washers. Perhaps I still can make a roof rack mount and incorporate these clumsy things.

Important note: one has to be careful that the bolts/screws used are only long enough to just go through the 10 mm nut on the backside of the hinge. If too long, the bolts will hang up on the hinge when the pop top is lowered.

Trip – Camper Creek watershed

Just back from a couple of days exploring the area NW of Port Renfrew. My wife and I made a trip there back in May but bad weather limited how much exploration we did. This time it looked like our summer had finally arrived so we headed out there to see what was what. Turned out the gate on Grierson main was locked so we could not make it up to the nice view point we camped at back in May, so we headed west on Camper main and found a spot just on the southern edge of Walbran Provincial Park. Yup, another campsite on a logged off area – we joked about writing a book “Slash Camping on Southern Vancouver Island”.

But the view was magnificent, looking over the logged area of Camper Creek watershed, to the south and west the virgin forest of Pacific Rim National Park (West Coast Trail), and Juan de Fuca Strait and Washington to the far south. This panorama doesn’t show the park boundaries, but just to orient you, Port Renfrew is pretty well behind that dip on the left.

I’m not going to go on and on trying to defend our habit of camping on logging spurs, we’re just different, ok?

A bit of haze was coming in over the straits as the sun set.

Next morning, thick marine cloud had arrived.

We packed up and headed down the slope and further west, exploring spurs and dead ends. All the way to the Pacific Rim National Park boundary. On the way we found another logged view point. You almost can see our first night spot back up on the ridge to the left, middle of pic, narrow vertical grey logged area.

About 950 metres further west is the National Park boundary, it is logged right up to it.

I don’t know why I take pictures of giant stumps without some object in frame to give an idea of size, but I do. This cedar stump really is bigger than you think.

Had a look at Sandstone creek.

And then back up to to the previously scouted campsite.

It really wasn’t that bad. See the cloud still on the deck in the background?

The low cloud made the sunset quite spectacular.

The cloud started to form around us after the sun went down.

And in the morning, we got the cloud full on. Damp and chilly.

On our way back home, we stopped at a spot on the Gordon River, a few km upstream of the marina.

All in all a pretty good trip. No one got hurt, no van problems, no run ins with bears (plenty of bear poop around), and plenty of food and drink. What more can you ask for?

Addendum: some more pics from trip.

We often came across signs of cedar shake block cutting, folk salvaging something from left over wood. On this trip it was all Red Cedar, on our previous trip in the area we saw Yellow Cedar shake block cutting too.

Apart from locked gates (mostly to restrict access to active logging areas – protecting machinery), many roads are “decommissioned”. Can take the form of large ditches and gravel berms across road, or taking out bridges. The latter shown in this pic, and a tree across the road to stop folk before they go over the edge.

My quick and dirty levelling ramps worked fine.

One of our two dogs looking noble. We don’t usually have any problems with them and the local wildlife but they have chased off a bear on another trip.

And here he is, dog tired.

As I mentioned before, lots of bear poop around. I think the bears are feeding on Salmon Berries.

Another shot of the marine cloud and West Coast Trail boundary. Where I took the pic the temperature was in the mid to upper 20’s C. Next day when we were in the cloud it was around 14 C. We were sympathetic for the hikers on the trail, they probably had no idea it was so nice and warm 150 metres higher.

Not the biggest slugs in the world, but pretty big.

Some of the sandstone outcrops.

Sunny day brings out the TR6

Posted by albell in other cars on July 5, 2012

Chrysler Royal Coupe

Posted by albell in other cars on July 5, 2012

Found at a family get together. I think it is a ’48, to tell you the truth I forgot to ask.

Vanagon – oil pressure sender relocation

Posted by albell in vanagon, vanagon mods on July 5, 2012

Been fooling around with relocating the high and low oil pressure switches so that I could add an oil pressure gauge sender and an oil temperature sender. There are commercially available kits to do this, but once again as I am cheap and keen to use the lathe, I made my own version (heavily influenced/inspired by Tencentlife’s work, shown here). A bit of aluminium rod, machined some flats and tapped some holes, some 1/4″ soft copper, compression fittings and a bit of fuel line to cover the copper. I used my spare motor to mock up install, probably needs more tweaking in the line, and will perhaps have to make a hole/slot in the rocker shield. Relocating the rearmost (is it the low pressure or high pressure? Can’t recall – ok, low pressure sender on left side, between pushrod tubes, high pressure sender on rear, below and to right of oil filter mount boss) sender frees up that spot for a temp sender.

ATA – Sikorsky S61N

Posted by albell in aircraft, around the airport on June 30, 2012

Been a while since last aircraft pic, but spotted this one for first time today. Owned by VIH, but not painted in their colours.

Vanagon – another use for scrap aluminium

Posted by albell in syncro, vanagon, vanagon mods on June 25, 2012

This time a bit of aluminium grating and it couldn’t have been easier to make – I cut it into two sections. Looks like it might work out in the field using rocks or wood to raise one end. BTW, my transmission bash plate seems to have generated a lot of chatter about increased transmission temps due to reduced air flow over the transmission. As with most internet chatter, no data given to support opinions but I hope to be able to do some temp measurements using IR gun (yes Simon, I’m going to ask to borrow it).

Vanagon – syncro bash plate project finished

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on June 24, 2012

Well the transmission protection part anyway. I decided to leave the plate mostly rectangular, but I did have to curve the front corners for no other reason than I thought it looked better. I also drilled some drain holes at the rear of the plate. Instead of using the drill press, I used the wrist buster, aka Van Dorn drill.

I made rather ugly holes with it, but I rationalized that (and other goofs) with the “it’s only a skid plate” mantra. I cut out slots for the stock skid bars and bent up the leading edges slightly. You can’t bend up that middle section too much or it will hit the nose cone of the transmission. I also gave the bottom of the plate some DA love.

I found it a real pain in the arse installing the stock skid bars by myself, but installed they were. See how exposed the transmission appears? Like having your goolies hanging out.

And same view with the plate installed.

Front view.

I think the extra width will help protect the inner cv joints and the fuel pump. Note to Simon, will also protect the speed sensor and that big electrical plug on driver’s side. But not sure about fitment around exhaust on your 2.5 Subie.

Next job will be to add some 1/4″ aluminium plate between the propshaft protection bars, and perhaps to extend that protection out sideways and attach to frame rails. That will help protect shift linkage and coolant hoses.

Damn. just occurred to me, forgot to paint the stock skid rails where I ground off the paint for welding the tabs on. I guess the project is not quite finished.

Vanagon – syncro bash plates project

Posted by albell in syncro, syncro specific repairs, vanagon, vanagon mods on June 22, 2012

I left the entire syncro drivetrain protection bars off my van after the propshaft business with a mind to installing some bash plates. The transmission is left pretty well fully exposed in the stock set up, and today I started doing a bash plate in that region. I had some scrap yard sourced 5/16″ aluminum plate to use.

Here are the stock skid bars/rails, transmission end. See the added tabs?

I had my first go at TIG welding…I still have a long way to go.

A real welder (good friend Dave) did the stainless to plain steel weld (609 rod).

Pretty heavy gauge aluminum, but it was cheap.

I match drilled and countersunk holes in the plate to match the nuts on the rails. The tabs with nuts were not located with any special measurement in mind.

Other side view. I’ll offer the assembly up to the van and see how much of the plate I’ll cut away. Rough sketches on plate sort indicates my thinking, “wings” towards the rear to provide a little protection to the inboard cv joints.

Project finished, blog post here.

Vanagon – radiator replacement (mine)

Posted by albell in syncro, syncro specific repairs, vanagon on June 21, 2012

Not really much to add to the previous rad replacement expect that it is my van (’86 syncro) and I thought I’d make it a post just for my documentation/memory aid purposes. I suspected my rad needed replacement for no other reasons than I think it is the original rad and that I noticed the rad fan coming on more often when idling after a hwy drive. The replacement is a Behr unit, made in South Africa. The old rad still had the a/c condensor rad attached in front, probably not helping heat escapement. The new rad did feel lighter than the old one, whether this is due to deposits in old rad or construction details I can’t say. No real details to note except that it is a pretty easy job. I clamped off the coolant lines so a total coolant replacement was not done, I glued on the little rubber washers on the spikes on top and bottom of the rad (so that they didn’t fall off during installation, and I sprayed Fluid Film on exposed fasteners in the general area. After install and bleeding, I have only idled van long enough (took 20 minutes) to get first stage of fan to come on, no road test yet.

Workshop find – Pug with a Pipe

Another discovery made whilst cleaning up my stepfather’s workshop, a pug with a pipe! Both my mother and my stepfather did not want it, so I snagged it before they changed their minds. Some folk have no taste eh?

It’s hard to get a good shot of it, size and glass working against me, but here is one attempt.

Interesting stuff on the back, label indicating it was purchased in England?

But the paper glued down to seal backing to frame appears to be from an American newspaper, fashion and automotive sections!

My prime evidence of it being at least a North American newspaper.