Archive for category vanagon

Vanagon – minor transmission work.

Small stuff. First off, I changed the transmission oil from the Castrol gear oil that I put in back in 2011. This time I’m suing Swepco 210. Lots of discussion about gear oil on the Samba, Swepco gets a good rap, many are running 201 and more recently more are using the moly containing 202 or 212.

So after 6 years and over 100,000 km the transmission plug magnet looked like this. Not too much swarf.

The second thing I did was to add more holes to my homemade transmission skid plate. Blog post about original install here. Yes, the relative lack of ventilation holes finally got to me. Even though I live in a very temperate climate, and I don’t do many long distance hot weather high speed trips, I knew I should have more air going over the transmission. Drilled more holes ( and didn’t measure spacing, but no one is going to see that are they?) and also put in some slots. And as I am always game for a questionably valid idea, I put in a bit of plastic hinge material art of the slots and infront of the holes.

Here’s my thinking. The plastic strip will create a little bit of high pressure in front which will help direct air flow up into slots, the strip also will trip the air flow and make a lower pressure area directly aft of it. It’s all pretty shaky fluid dynamics but what’s the harm in trying?

Green is air flow, gray is skid plate.

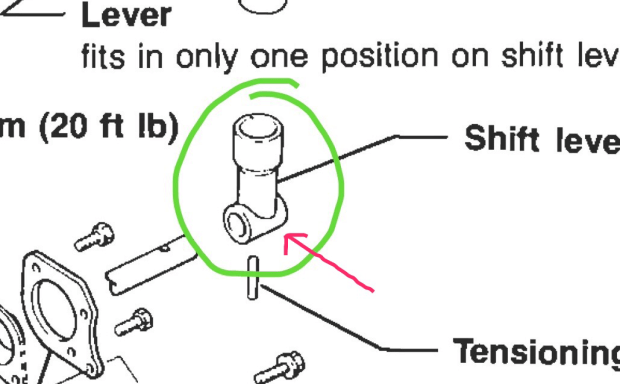

The last thing I did was adjust the ball and cup part of the gear shift linkage. The parts circled here.

But what adjustments can you make with that assembly you ask? I didn’t think there was any, I was thinking the fit of the ball into the cup was worn and loose. This supposition was a little bit of a Hail Mary wish, I had been having some shifting issues. The first to second, and the third to second shifts had been getting harder over the last few months. It felt like the linkage was hitting a stop rather than anything internal with the transmission itself. The low hanging fruit was this part of the linkage and I thought I’d have a look before working forward with adjustments to the rest of the system.

I think the specs for the ball and cup are that the cup has an ID of 30mm and the ball OD is 29.6mm. I was wondering if things were worn out and the fit sloppy. You can buy replacements. And also I was wondering if the splines on the ball part, where it fits in the splined shaft in the transmission, were worn.

Going at it I remembered that a previous owner had made a modification. The lower part of the cup lever had been cross drilled through the horizontal shift rod and tapped and nutted. The stock method of securing the cup lever to the shaft is a small roll pin coming up from the bottom. The red arrow approximates where the cross drilling was done.

Took the parts off and the cup and ball fit wasn’t that loose at all. But without the added cross bolt the fit of the cup lever onto the shaft was very wobbly. When I tightened up the cross bolt the fit became very secure. And miracle of miracles, tightening that bolt cured my shifting issues.

It would be a little bit of a chore to drill and tap the connection on the van. I think this was done when the transmission was rebuilt ( the previous owner mentioned, but had no paperwork proving, that the transmission had been rebuilt). Maybe this mod could be of use to some of you out there. It’s something to be aware about if you are putting on a new cup lever, check the fit on the shift rod.

Vanagon – the ignominy, the shame, the wages of procrastination (ball joint)

A few weeks ago I replaced an upper ball joint on the van. This was not preventative maintenance, this ball joint was dead.

The boot was ripped, and you can see the grease had long gone. I have no excuse for this lack of awareness of the joint failing. (You know, I think it might even be the original joint)

I replaced the other side’s joint some years ago, blog post of that here. Good god, it was back in 2009. It was a real chore to get the tapered part of the joint out then and I expected more of the same this time. But apparently god smiles on fools, and the tapered part practically fell out of the steering upright. Back in 2009 I used a Lemforder joint, which I think are pretty darn good. But couldn’t get hold of one quickly this time and went for the Febi version. I don’t think I would have touched any other brands, those two are the best. So do you think the Febi is actually made in Germany? Says Germany, but not made in Germany 🙂

Yeah so that all went fine, no drama in the install.

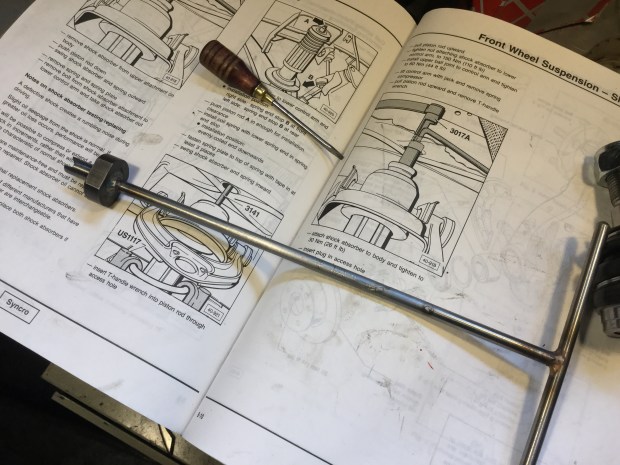

But I made life harder for myself. That strange looking tool in the picture of the new joint on Bentley may give a hint. The too was my quick effort to make something to hold the shock shaft while the nut is turned. There is a neat VW specialty tool for this.

And during my previous spring removals I’ve not needed to hold the shock shaft, the nut came off land went back on easily. But this time there must have been some damage to the threads and the nut was not cooperative. The tool was made from scrap hence the unusual shape at the business end. Really just amounts to a rod with a slot in the end to hold the flattened end of the shock shaft.

Yeah I was swapping springs again. Back in 2013 I installed 2wd westy front springs. They are a few cm longer and the wire diameter was ( and I remeasured) only about 0.5-0.8mm smaller than the syncro springs. I can’t give you better measurements than that, the paint thickness muddies things up. Back then I thought they were really the same wire diameter. But now I wonder. Anyway, the post about that is here. Over time I started to think maybe the syncro springs were stiffer or that the 2wd springs had sagged. Maybe they are, maybe they aren’t, but I had my old syncro springs sand blasted and I repainted them. Here is the shorter syncro spring beside one of the 2wd westy springs I removed.

Well I don’t know. Probably should have left them in. But I didn’t and I had the fun struggle of spring swap. The other two tools I find useful, if not essential, in the spring swap are a ratcheting strap clamp to pull the shock into alignment and a guide tool to screw into the shock shaft to lead the shaft up through the shock tower. I made the latter years ago with a wooden knob for a handle. After I conked my forehead with the knob when I pulled up hard, but the rod was not screwed on securely to the shock, I changed the knob for a T handle.

Here’s the original at work.

And the highly recommended T handle version. Just a bit of tubing welded to the end.

And… I finally, after a year, got around to replacing the driver’s side lower control arm inboard bushing with a polyurethane version. The original was just thrashed. All distorted, the control arm pushed forward in the mount . Hard to see in the pic, sorry.

This pic shows it better, you can see rubber bushing in the aft end but not on the forward end. Forward end of bushing all worn off.

Getting the rubber bushing out of the arm requires some threaded rod and bit of this and that to make a little press.

The polyurethane bushings are two part with a common sleeve, so it’s quite easy to push them in the arm.

Well that sums things up. But it doesn’t convey the agony of an old man on a gravel driveway working, again, on the van 🙂

Vanagon – Thule ski box lid struts

Hey you know the strut I used to support the westy kitchen lid? This blog post. I had three left over looking for a home. Got to use two today in my old and venerable Thule ski box. Phil is wrong when he says it’s a clunky, ugly, and heavy old thing. Its a classic, and it’s strong with double wall construction.

But it has one annoying feature when used on the van, the stock support strut doesn’t hold the lid open enough for loading some things.

Gas struts to the rescue!

Vanagon – awning guy line tensioners

Posted by albell in vanagon, vanagon mods on May 21, 2017

Catching up on blog posts, some little things…

I have a Shady Boy awning on the van. Gosh, it must be well over ten years now and it’s worked well for us. But I never liked the plastic tensioners used on the guy lines. Came across some nice tensioners online, made by MSR and called “Camring Cord Tensioners”. Here’s a link to Mountain Equipment Coop listing. They looked pretty cool, thought I’d make some knock offs.

But whoa, you say, why bother making them when they are only about 11 bucks for four? Good question, I have no good answer. And to be honest, a little bit of me dies when I copy a good idea.

Ok, enough of that. Here’s a pic from the MEC link of the originals.

Nice aren’t they? Nicely finished and anodized. I just guessed about the dimensions and used the stock I had on hand to come up with these.

Thicker wall tubing and not as nicely finished. I replaced the old Shady Boy guy lines with some paracord and the tensioners.

I suppose if you are going to shamelessly copy a design make sure you copy a good design. And this is a good design, tensioner slides up and down on the guy line easily with a twist of the ring, and holds firmly when set.

Shoot, forgot to give approx dimensions for my copies. OD is 1.25″, 1/8″ wall, 1/2″ long. 1/4″ holes, 3, drilled 90 degrees apart.

Vanagon – Sexy Simon’s van in Guerrero Negro

With the paint fresh and fragrant, the vanagon heads north up the peninsula.

Vanagon – It’s a delicious spangle!

Just got the pics from Simon in Mexico, and the van is painted. Its Honda sunburst orange with black strip on window line and rockers. Simon says the colour really changes with the light and you can see that in the pics. I think it looks great, almost lickable 🙂

Addendum May 12, 2017.

Trevor commented that it reminded him of the new Air Canada livery. Yeah, I can see that .

Vanagon – Simon’s hightop primed

Maybe more bits and bobs should have been taken off the body? I’m guessing the next pics will show the colour choice.

Vanagon – Simons update from la Paz

He’s doing it, he’s getting the van painted, no turning back now.

Also, he saw the Go Westy entrant in the 2017 NORRA Mexican 1000.

Simon writes: I met Lucas of GoWesty fame there, he mentioned that the rig has the new GoWesty 2.7L bored-out WBX (hadn’t heard of that, forgot to ask him if it was ‘super-duper’). 🙂

Cheeky Simon.

Vanagon – Simon’s trip continues

Making his way to Baja, where some surprises for us are in store. Yeah, he’s getting a paint job in La Paz. Before the stuff hits the fan here are some recent pics.

It’s a bit of where’s Waldo?

That last pic is another study in contrast with the hulk to the right. Yes

I think the van looks fine as is, but the heat is getting to him and he’s thinking of a colour change. Heat is not a problem up here in B.C.

Vanagon – AA rechargeable LiPo battery

These are new to me and I think the idea is great. Don’t need to pack a separate battery charger, just pop the cap (cap has short elastic lanyard) and plug into USB port. Little led light on the cell goes from red to green when fully charged. The mAh rating, 1200, is less than an alkaline (not sure how it compares to NiCd or NiMH) and the discharge profile is different. That discharge profile is flat with a sudden drop at end, so the cells may not play nice with the battery life indicators on some devices. Ie, your camera may show close to full battery then suddenly empty.

I’ll give them a go and see what’s what.

Vanagon – campsite at San Miguel de Allende

On this side, the friendly multi-generational line up.

A bit of a Spike and Chester thing going on

Link to the campsite

Vanagon – update about minor mods

Posted by albell in vanagon, vanagon mods on April 10, 2017

I’ve been kinda quiet in the last few weeks about minor vanagon hacks and mods, my weekend time has been taken up with other chores. But I have a few things percolating in the workshop; some propane fridge modifications, yet another led strip for interior lighting, and a “new to me” connector for the solar panels.

I think the fridge mods will be the first finished. I have this extra fridge in the workshop that I gave a complete R&R. Having it on the bench let me try out some ideas around enhanced cooling of the fins. I just have to hook up power and propane and give it go.

Oh and I’ve been playing around with the already tried mod of a PWM motor controller for the ventilation/heating and rear heater fans. It works well and would be a reasonable fix if the resistors in the stock system fail. I’m dithering about whether it’s worth installing in a functioning system.

Vanagon – kitchen unit lid strut support

Posted by albell in vanagon, vanagon mods on March 30, 2017

I have the older type kitchen lid ( because I used 82 westy kitchen unit in my Syncro tin top to westy conversion), I think it changed post ’88 but not sure. The change was to the leading edge of the kitchen unit, lowering it which allowed a little more reclining of the driver’s seat back.

Anyhoo, I think both versions use the annoying “broken leg” style support strut to keep the lid up. I really didn’t like the strut. Finally today I changed it. Used a gas charged strut bought from banggood, the listing is here. It’s a small strut with 100 N (around 10kg force). I wish I could have used at least some of the screw holes from the stock strut but hat wasn’t possible.

And how does it work? I’m telling you Simon, ITS THE BEST MOD EVAH!!!

It is good, i was concerned that 100 N was too strong, but the placement of the strut in relationship with the hinge etc turned out to be perfect. And as a bonus, and this wasn’t planned explicitly, there is an “over centre” force from the strut when the lid is closed which gives a satisfying positive latching force. But I do I wish the old screw holes were gone.

Addendum May 2017

As requested, some measurement pics. Enough there to give you a start.

Vanagon – led rear side marker light prototype

Posted by albell in vanagon, vanagon mods on March 26, 2017

i took the mock up circuit described in my post the other day and rewired, sealed, shrink wrapped, connectores added etc,etc, and installed the led lamp with an unpainted aluminum guard onto the van. Pics show the lamp lit as running light ( as normal).

Looks fairly ok right? But I have to confess that I misled you in the last post about the led lamp size. Yes it’s not as tall, and just slightly less wide. But side by side comparison with the stock unit makes it look very much smaller overall.

Bet you didn’t think it looked that much smaller in the first pics. The flasher function works well.

I’m fairly pleased with it, and if I paint the guard black I think it will look better.

Vanagon – trivial little things

Posted by albell in vanagon, vanagon mods on March 25, 2017

Maybe I’m scrabbling for content. Content as in copy, not the state of peaceful happiness. In any case here’s some dross.

First up is a Syncro badge. It’s from the same 91 Passat Syncro that gave me one of the instrument clusters I posted about a few weeks back. Kinda nice little thing and it’s interesting that the date of manufacture is February 1990 and it’s marked made in West Germany. Wasn’t until August of that year that the two states officially merged. I find it so hard to believe that someone born then will be 27 this year.

Next are led lights for the front turn signal/running light. So many choices for this light, I ended up with this unit from Banggood. Supposed to be a “switchback” light, well that’s what I thought. I was expecting the running lights (the white led elements) to go out when the amber turn signal elements are powered. And if you read the reviews you’ll see that at least one buyer had a bulb that worked that way. But both of my bulbs don’t waltz to that tune. The white elements remain on while the amber elements flash.

On the van, the bulb in the holder, by switching the positions of the two power wires ( one the flasher signal and the other the running light power) I could decide if I wanted the white led elements to be the running or turn signal lights. Decided on amber led elements for running lights and the whites for turn signal. Hey they work pretty well but jeeze I wanted that “switchback” effect 🙂

And finally a preview of another silly project I’m working on. A while back I discovered a rear side marker light replacement for the stock vanagon unit. It’s a little narrower than the original but the length is okay and the screw holes are right on. Trouble is that it’s rated as 24 volt. So I ordered some cute little 12 to 24 volt boost converters. Well it turns out that the lights work fine on 12 volts, certainly bright enough to be used as is. But then I had an idea. How about if I tap into the rear turn signal power so that the side marker would light up brighter with the turn signal power. Simply put, the side marker gets 12 volts as usual, but the turn signal power goes through the boost converter. I set up a crude set up and it works out fine. In the video you’ll a spot light to provide some load for the regular flasher unit ( I have an electronic flasher unit installed in the van and that plays nice with the led front turn signals), and you might notice the two diodes in the circuit to stop power going the wrong way. I’ve got some aluminum guards to paint before I install this in the van. I’ll show you more later.

Vanagon – extinguisher holder

Posted by albell in vanagon, vanagon mods on March 12, 2017

It’s already March and only now do we get the first entry for the “Silliest Vanagon Mod of the Year Award”

I decided to relocate my fire extinguisher from behind the front seat to the stock westy location at the sliding door. Here’s an old pic of the behind the seat location.

It’s just a bit of pvc tubing mounted to the cabinet and really it worked quite well for years ( originally in my 82 westy and transferred to the syncro). But with the solar panel charge controller on the same cabinet face, making the connections to the portable panels was more awkward with the extinguisher there.

But the harebrain fairy must have visited me during the night, I ditched the pvc tube style mount and and went leather.

I’ve got a bunch of full grain leather off cuts, all different colours and none very large. So silly things like this use them up.

Vanagon – high top syncro at Joshua Tree

Simon is making his way south. Up here is has been sitting around 4C and rain, he’s hitting 37C and dry. The bugger 🙂

Check out that bike rack.

Vanagon – alternator remix and a real surprise

Posted by albell in vanagon, vanagon mods on March 5, 2017

Back in January I had to do an emergency bearing replacement on the old wbx alternator. The local NAPA store had the bearings in stock (no name bearings, sigh) and the job went fast and worked. While I had the alternator apart I cleaned up the commutator but I noticed the copper was getting very thin and probably wouldn’t last much longer. I don’t know how to replace the commutator, or even if it’s possible to do that at home.

Yesterday when I picked up the Passat gauge clusters at the wrecker yard I also grabbed a Bosch al34x alternator ( also from a Passat), suffering from a brain fart thinking it was a direct swap into the wbx. Of course it ain’t, the bodies are different.

The al34x is on the left, a broken ( severed wires from stator to diode pack )a parts wbx alternator on the right. Note the different mounting.

So today I tore the al34x apart and mounted its rotor, bearings, diode pack, and stator into the wbx housing. The biggest chore when working on alternators is the fekkin hard to loosen machine screws. The long ones that hold the body together and the short ones on the bearing retainer plate and the diode pack. I’ve seen both slot and Phillips head in these, either way you have to use all your guile to get them loose.

First the brush pack get pulled (you all know how to do that ) then the plastic on under the b+ and the “blue wire” (damn I forget the number designation ) terminal. The handy 1/4″ drive tool shown, I’ll talk about more later. And the pic shows that the alternator was a “premium ” rebuild. Premium, ha!

The 1/4″ drive tool set I’m using has screwdriver bits.

And even being a cheap set the bit was up to the task of removing the long machine screws holding the housing together. That is after I used a regular screwedriver and hammer to give each machine screw a good rap. Then same rapping and grunt to remove screws from bearing retainer plate ( plate is internal but you have to remove the four screws before you can get housing apart).

After all that and some love with the soft hammer, the housing comes apart.

Then you pull the rotor out.

Well it looks like I struck out hoping that the commutator would be relatively fresh. It’s not, it’s more worn than I hoped. But that’s not the surprise mentioned in the blog post title. Remember this is a Bosch “premium” reman.

See it? The machine screw? It’s supposed to be in the hole just down and to the left, in the diode plate. I mean really, it came loose? Does this alternator actually work with that screw up there doing who knows what sort of mechanical and electrical mischief?

It’s bent.

Well I’m in so deep, time and money, so I might as well finish things. The rest of the diode pack screws were not easy to remove. Too late I’m telling them, you can’t make up for your weak buddy. You can move the stator around a bit, careful not to stress the copper wires, to get at the screws. Then pull the diode pack and stator out of that housing and pop it into the wbx housing.

If you’ve made it this far you’ll know that putting it all back together is just the reverse 🙂 just keep an eye on the alignment of the two parts of the housing.

And there we are, guts swapped. Maybe it works but too late in the day now to test it. Man, I can’t get over that loose screw.

Hey, the 1/4″ drive tool I used a lot on this job is a cheapo set I bought a couple of years ago at Princess Auto. If you’re Canadian you know what that store is. I found it on sale, I think under 20 bucks and I have to say I really like it. It’s actually very well made, the ratchet could be finer of course, but jeepers for the money it’s great.

Addendum March 6 2017

Both for my education and to clear up any incorrect terms used above (and a nod to david B.) I submit this cutaway labelling the parts in the alternator

Vanagon – anticipation of new wiper washer nozzles

Posted by albell in vanagon, vanagon mods on March 5, 2017

I’m on the list for a set of new wiper washer nozzles designed and built by Forrest Whitmore. His samba thread about the nozzles can be found here.

I don’t know of anyone who is really happy with the stock nozzles and the spray pattern they make. And over the years I’ve been less than happy with the washer pump performance. You sort of suspect some amount of voltage drop at the pump making the motor less than perky. I toyed with the idea of adding a new power feed and a relay but I got enough improvement by cleaning the contacts right at the washer switch up on the steering column.

Then the other week I was digging around the mess in the workshop and found a spare washer pump. So I says to myself, “go on, plumb it inline”.

Yeah but… if I was worried about voltage drop in the stock un-relayed circuit with one pump won’t having two pumps in that circuit be pushing things?

Yes.

But I did it anyway. Maybe I’ll put in a relay later, but for now I tapped the G10 terminal on the back of the fuse panel ( its hot when washer switch activated. It’s a feed for the headlight washer system, an option we didn’t get here in North America).

I simply cut the washer fluid tubing right behind the driver’s side headlamp, heated up the cut ends and slipped them over the inlet and outlet of the spare pump. Oh and luckily I had the plastic connector with pigtails so making the electrical connection to pump was easy.

That black boot ain’t quite pushed on enough in the pic below.

So how well does this work with the stock nozzles? You’ll think I’m exaggerating when I say it works twice as good. More volume and force ( it will shoot over the top of the luggage rack if not aimed right) and I’m going through fluid fast. Fast enough that I checked for leaks today. When I get the new nozzles I’ll post some vid comparing things etc.