Archive for July, 2024

Vanagon – rear seat molle panel

Posted by albell in vanagon, vanagon mods on July 31, 2024

This is not something I needed. But was just an idea I thought I’d like to explore . My front seat back molle panel I made and showed a while back is great, and useful. But one on the rear seat… well maybe. I have played with shock cord loops and shoes, sandals, boots before I had it powder coated … and that does work so I think that’s what the main use will be .

Anyway…

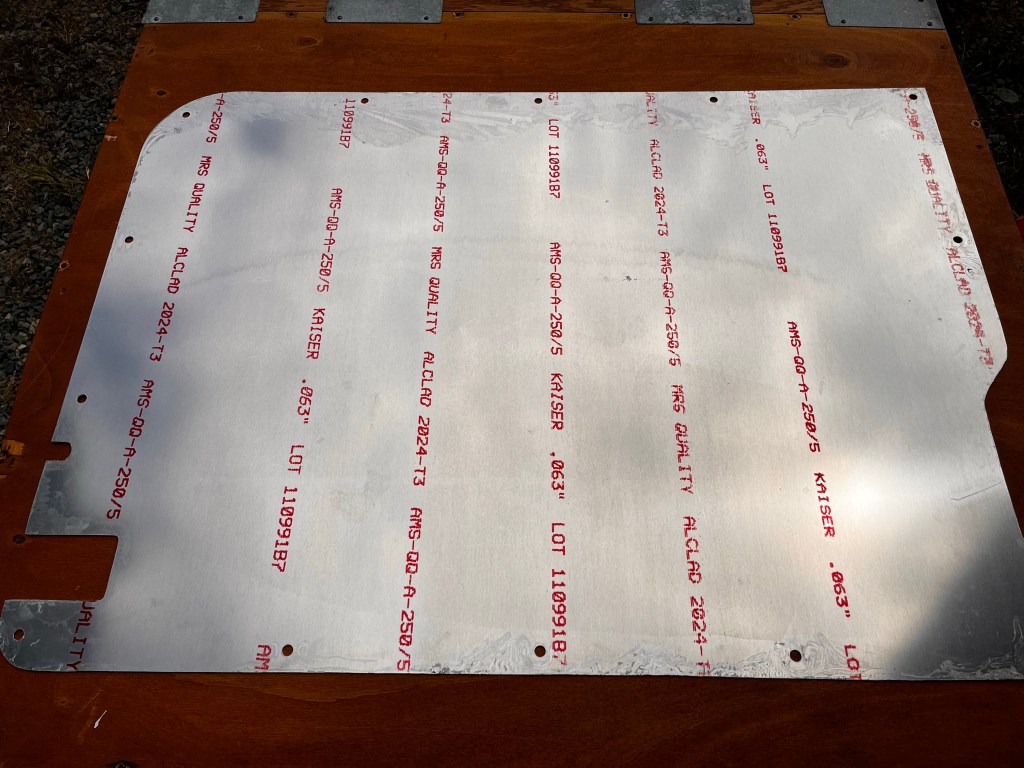

It’s 0.088” thick aluminum , powder coated slight texture satin black. I made some spacers with locating bosses to put in spot where I thought it need some more support. Bit of sticky pad ( not double sided tape) on those spacers just to conform and support better.

Mounting screws to stock bolt locations, countersunk and with support spacer there too.

Update …. Shock cord crudely attached… full house of foot wear

Vanagon – over the top slider door latch cover

Posted by albell in vanagon, vanagon mods on July 12, 2024

Update: Aug 2024

Finally powder coated and installed . Yeah not the best door card recovering, it’s a slightly waxed canvas.

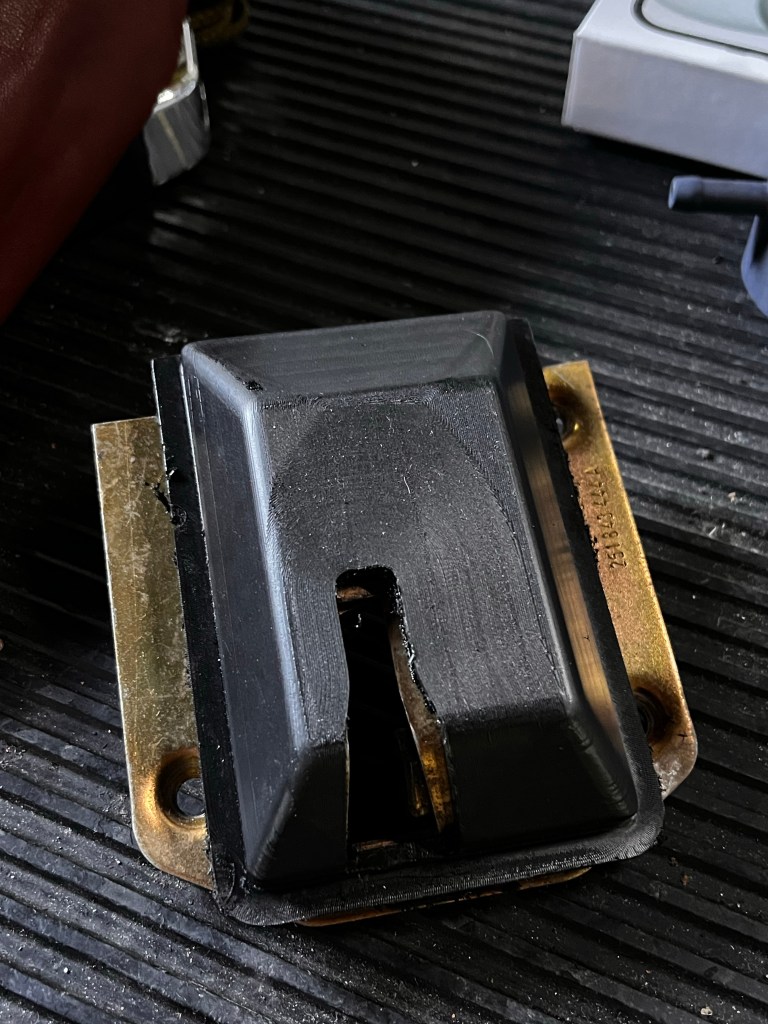

My stock plastic one is degrading . My spare is degrading . Degradation all round.

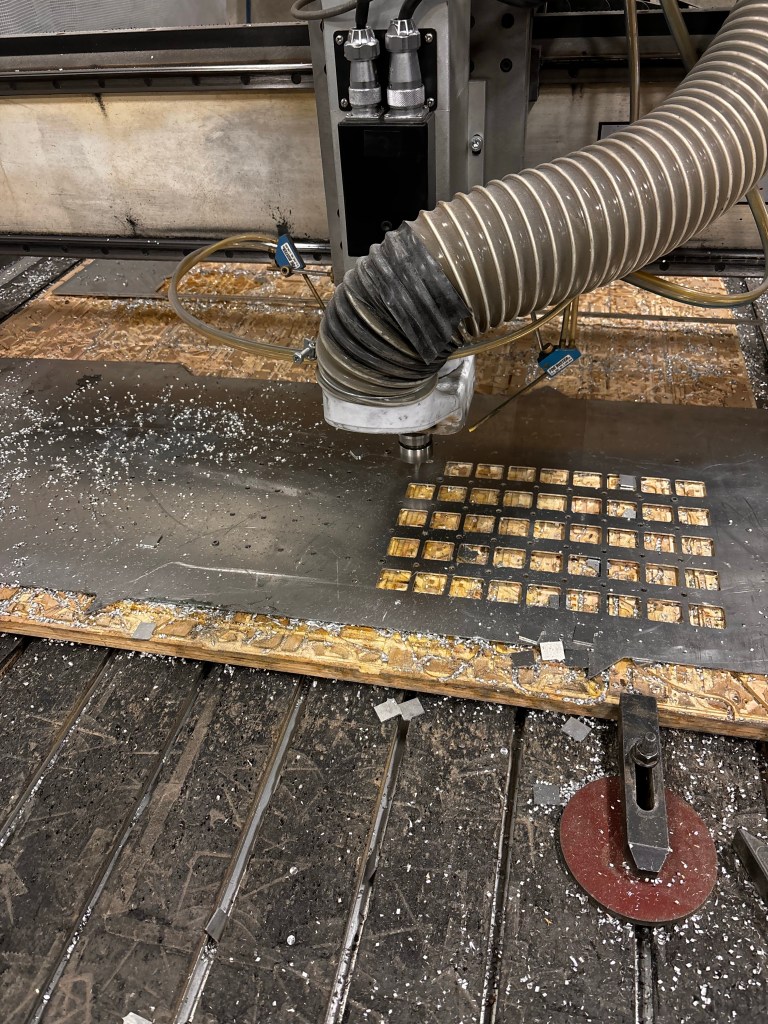

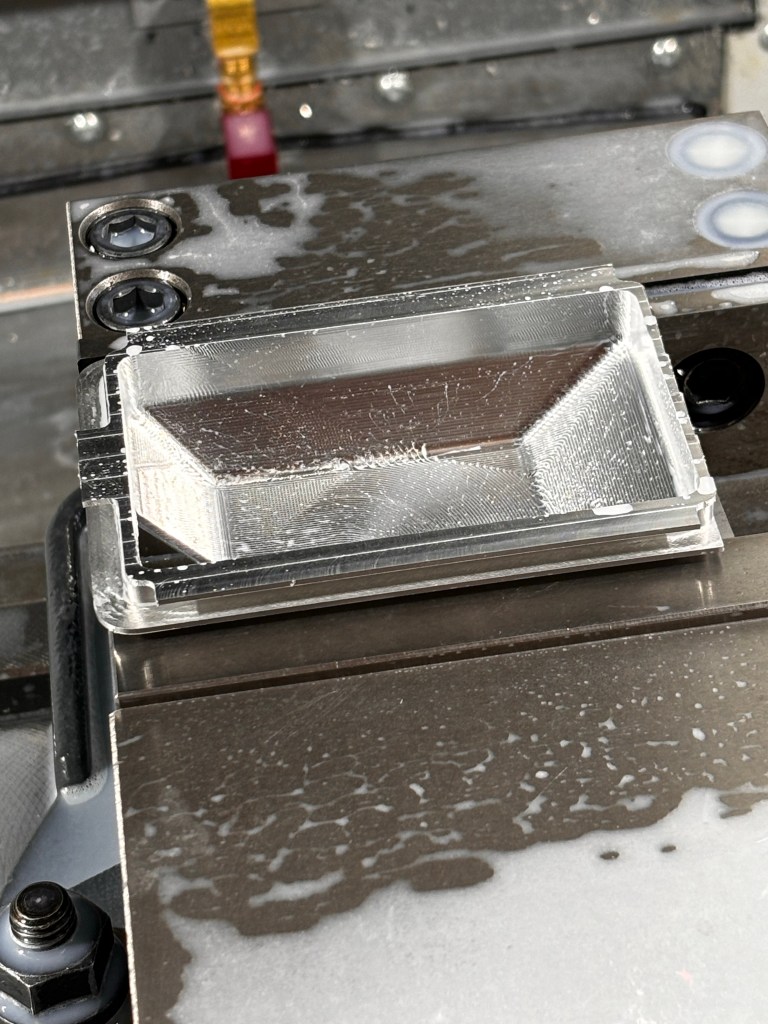

So I took one of my crappy stock plastic covers and really just measured up with calipers. Made a computer model and tried that out in hdpe. That plastic didn’t cut cleanly and I adjusted model cos the latch opening wasn’t right. Didn’t get that correction correct , but ok, good enough .

Went ahead with a block of aluminum , adjusted the shell thickness via stock to leave on the programming of cut . Turned out good enough .

Sandblasted it . I’ll powder coat black

Damn, forgot to add. If it fits I’ll post the step file of the model . you can 3d print it

Tools – sewing machine

Got this old singer 331k4 to do the canvas work I wanted to do on van. It’s a straight stitch industrial , clutch motor ,very fast.

I got it working ok, and learning to use it. Did I say it was fast? You that know, know that many convert the clutch motor to a more controllable dc servo motor. Or use jack shaft pulleys. Maybe one day, right now I have enough low speed control to do what I want.

Will punch through 1/8” leather even with fabric needle. Low speed control will be very very advisable if I’m going to do more leather. No second chance with leather.

Vanagon – kinda crazy recovering project

Posted by albell in vanagon, vanagon mods on July 2, 2024

A few years ago I made an aluminum door card for the slider door. 1/16” 2024 , I traced the stock card and cut the aluminum by hand. No cnc 🙂

Been using it naked for all this time. But I had bought some olive drab water repellent canvas ( pic says 15 oz, but I recall now that weight was out of stock and I bought 12oz), and the crazy plan was to cover it with that.

Now I say crazy, as why would anyone do interior trimming in olive drab lightly waxed canvas?

Well I wanted that look, and I don’t mind the slight odour the fabric has. Yes, it has the waxed canvas smell.

Oh btw, I made my tintop syncro into a Westy 11-12 years ago using the parts from my ‘82 Westy.

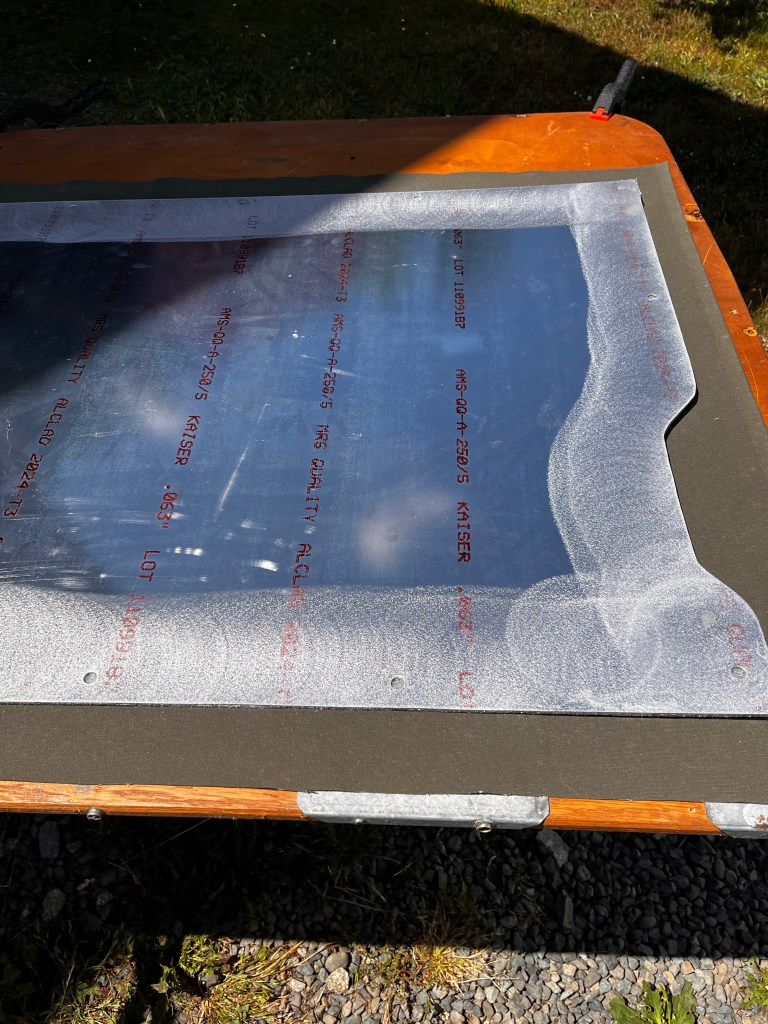

I glued some 1/8” closed cell foam to the panel and then glued the fabric to the foam and wrapped it around the back. I had tested my contact cement a while back, how well would it glue the canvas to the aluminum. I was surprised that it really did glue it well.

The pleats you see in the corner in one of the pics were trimmed flat. Used some fasteners I found online to attached panel to door, they worked well and for the most part reusable (90% removed without damage from the naked panel )

Next day I refoamed and recovered the rear bench. Was way overdue. The stock foam was degrading. I had some 4” foam , but not quite enough to do it properly. Should have 1/2” or so of foam sticking out from the plywood base. I had enough foam to be exact match with plywood , I added quilting stuffing material to pad things out .

Oh and I don’t have an electric carving knife to cut the foam, but a hand held hacksaw blade worked very well

Corners sewn, fabric stapled to back of ply as in the stock 82.

Oh and I used 4” thick foam. I don’t know the density but it’s close to stock. The stuff I took off was about 3.5” thick. But it was old and compressed a bit. But… I think 4” foam might be a tad too thick. It’s tight between the seat back and the base. That’s not a problem sitting, or deployed as bed, but it’s impeding lifting the seat base fully to get to storage . I’m thinking of what to do.